Vanadium dioxide (VO2) phase change material with beam-shaped nanostructure and preparation method thereof

A technology of nanostructures and phase change materials, which is applied in the direction of nanostructure manufacturing, heat exchange materials, nanotechnology, etc., can solve the problems of disordered arrangement of dimensional and nanomaterials, harsh preparation conditions, high cost repeatability, etc. Novel appearance, resource saving and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation bundle VO of the present embodiment 2 Nanostructured phase change materials, the specific steps are as follows:

[0023] a. Prepare the reaction solution: dissolve 2.5g of oxalic acid crystals in water, add 8mL of n-butanol, then add 1.5g of vanadium pentoxide powder, and stir until completely dissolved;

[0024] b. Pour the above solution into an autoclave, seal the autoclave and put it into a blast drying oven, keep the reaction at 260°C for 48 hours, after natural cooling, filter and wash to obtain a black powdery material;

[0025] c. Under a nitrogen atmosphere, calcinate the obtained black powder material at a temperature of 550°C for 60 minutes to obtain VO with a bundled nanostructure 2 phase change material.

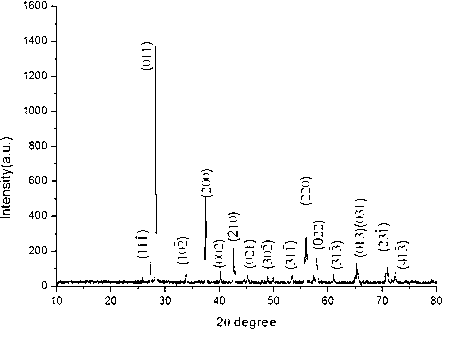

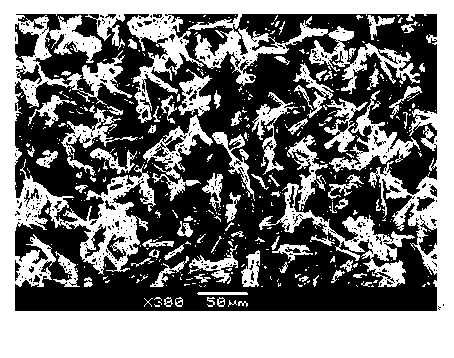

[0026] The bundled nanostructured VO prepared in this example 2 Phase change material, its X-ray diffraction pattern is as follows figure 1 shown. After scanning electron microscope detection, its SEM picture is as follows figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com