Method for preparing axminster carpet yarn

An Axminster, yarn technology, applied in the field of Axminster carpet yarn preparation, can solve the problems of low competitive advantage, large yarn loss, low production efficiency, etc., to avoid low production efficiency and reduce yarn production. loss, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

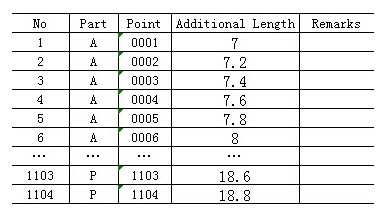

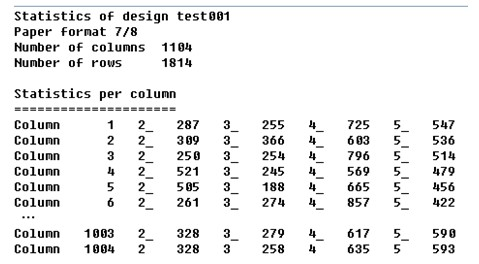

[0013] Embodiment 1: with reference to attached Figure 1-6 . A method for preparing Axminster carpet yarn, which comprises an Axminster carpet loom, computer software for pattern recognition and analysis, and an automatic winding machine for computer-controlled fixed-length winding. Computer software for pattern recognition and analysis is used to analyze and organize the patterns produced by Axminster carpet looms in PAT or BMP format with index colors, and output the yarns required for each color and each position according to the production process settings. Length and related information; use computer-controlled fixed-length automatic winding machine to automatically wind the yarn length at each position, and paste identification labels with yarn length, position information, etc.; in Axminster The corresponding position of the creel on the loom is used to hang the yarn, which can minimize the yarn loss during the production process.

[0014] Axminster carpet loom creel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com