Material stirring system for old five-steamer wine-making process

A process and technology of distiller's grains, applied in the field of mixing system of Laowuzhen winemaking process, can solve the problems of high dependence on raw material ratio, slow development of winemaking process, uniform and unstable mixing materials, etc. Achieve cleaner production, reduce operation difficulty and work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with examples. In the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

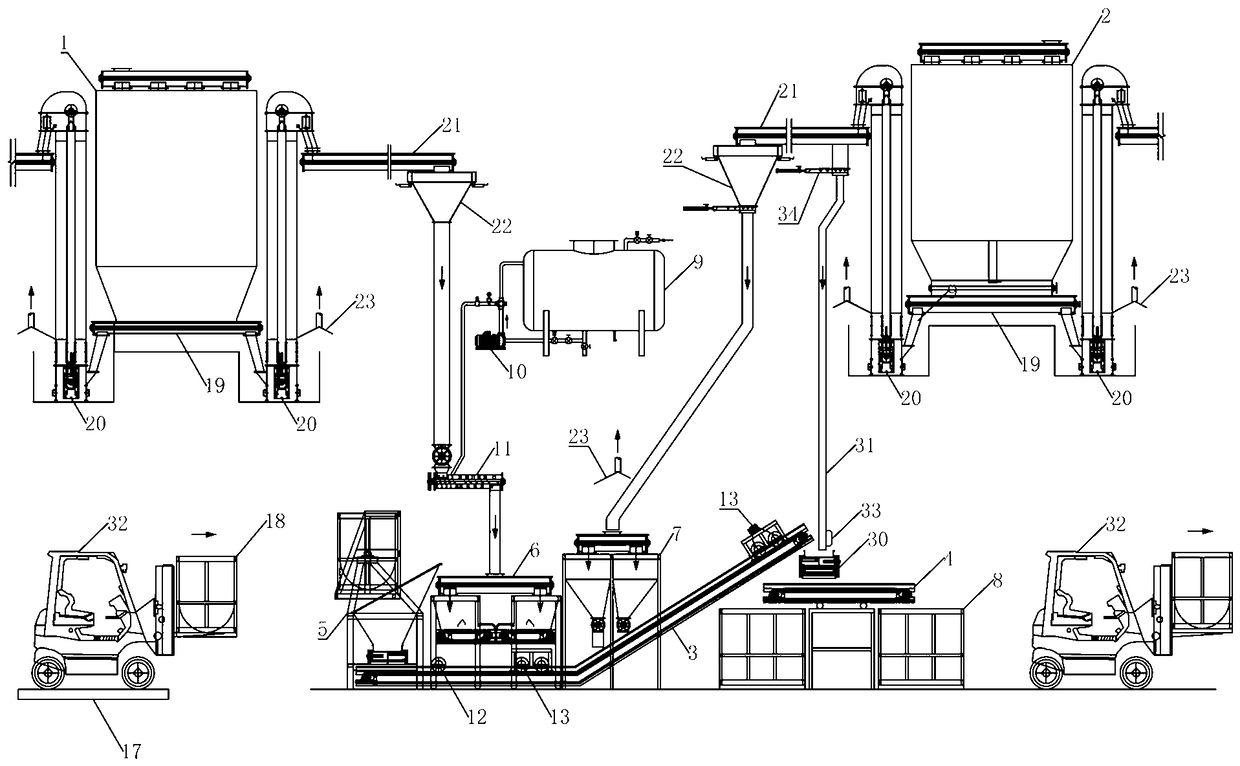

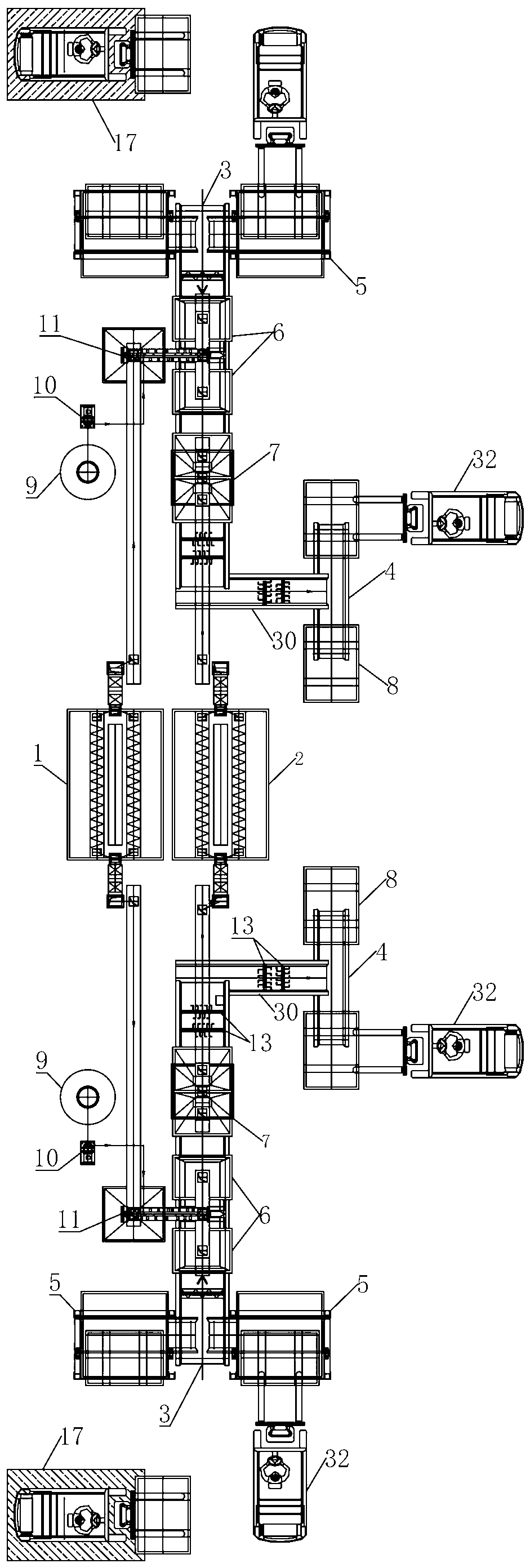

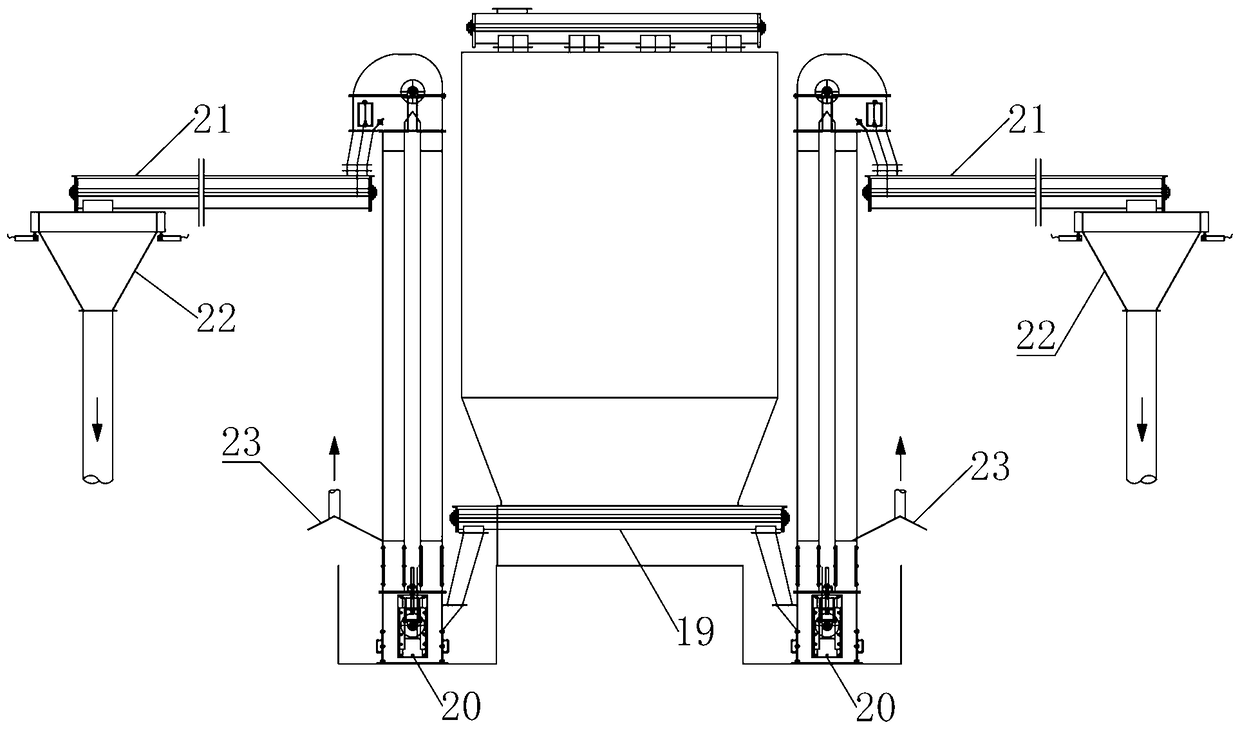

[0038] Such as Figure 1-9 Among them, a material mixing system used in Laowuzhen wine-making process, including a grain buffer warehouse 1, a rice husk buffer warehouse 2, a hydrolysis device, an ingredient mixing chain plate 3 and a distribution chain plate 4, along the top of the ingredient mixing chain plate 3 The conveying direction is provided with distiller's grains feeding device 5, grain feeding device 6 and rice husk feeding device 7 in sequence, and distiller's grains, grain and rice husk are added to ingredient mixing chain plate 3 respectively. The feeding device 6 is connected, the grai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com