A kind of flexible pressure sensor and its manufacturing method

A technology of a pressure sensor and a manufacturing method, applied in the field of pressure sensors, can solve the problems of high cost, high technical difficulty and high equipment dependence, and achieve the effects of low cost, improved sensitivity and reliability, and simple and convenient manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

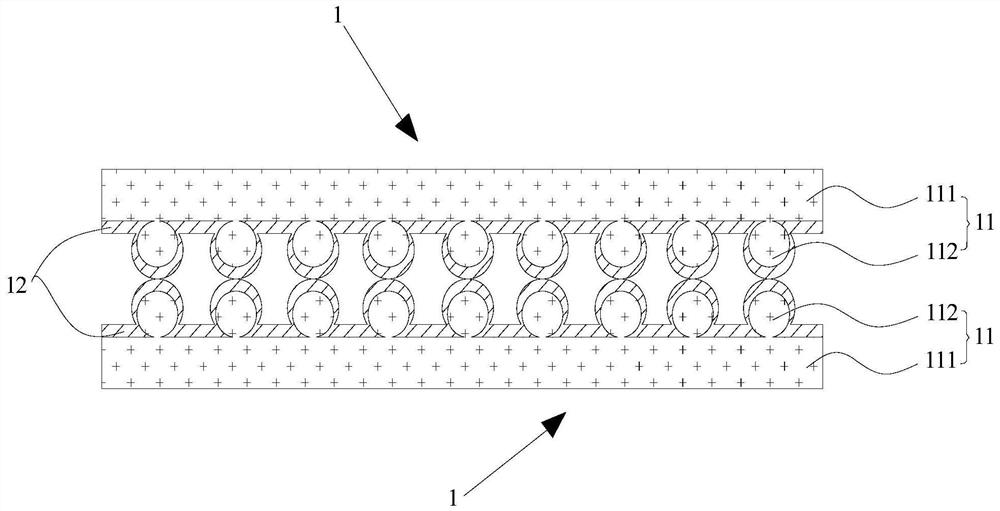

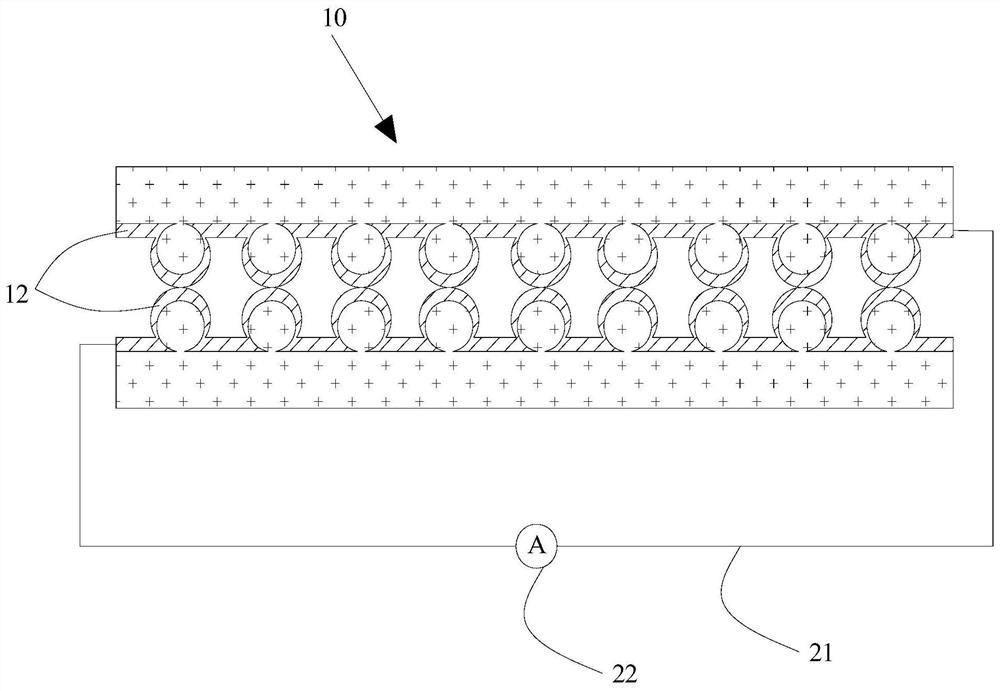

[0029] figure 1 is a schematic structural view of the flexible pressure sensor according to Embodiment 1 of the present invention.

[0030] Such as figure 1 As shown, the flexible pressure sensor according to this embodiment includes two electrode structures 1 oppositely arranged, each electrode structure 1 includes a flexible substrate 11 and a conductive layer 12 arranged on the flexible substrate 11, the two electrode structures 1 The conductive layers 12 are connected against each other; each flexible substrate 11 includes a substrate body 111 and a plurality of convex structures 112 disposed on the substrate body 111, and the conductive layer 12 covers the flexible substrate 11 On the surface with multiple convex structures 112, a complete flexible pressure sensor is formed.

[0031] In each flexible substrate 11, a plurality of protruding structures 112 are preferably integrally formed with the substrate body 111; at the same time, the conductive layer 12 completely co...

Embodiment 2

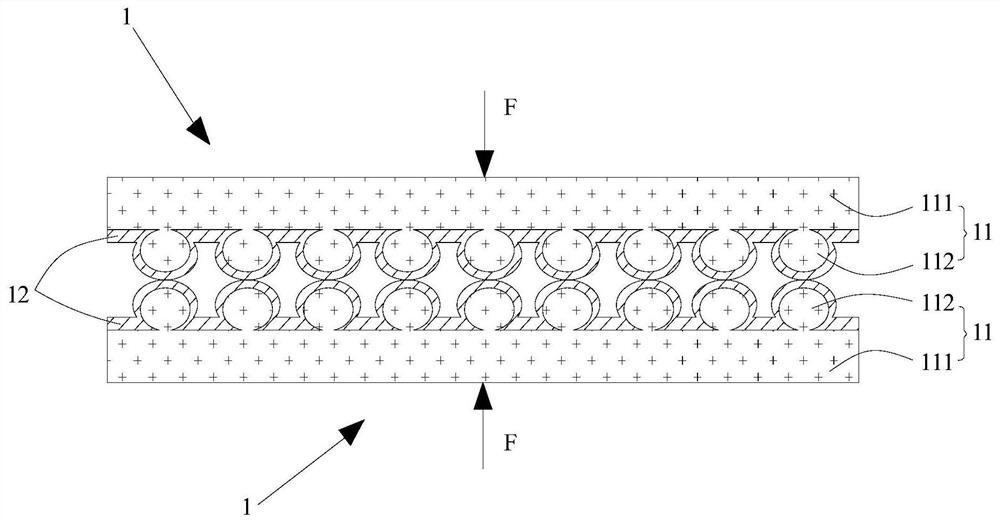

[0040] In the description of Embodiment 2, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. refer to Figure 4 , the difference between embodiment 2 and embodiment 1 is that the arrangement of the plurality of protruding structures 112 in the two flexible substrates 11 is different; in this embodiment, the protruding structures 112 in the two flexible substrates 11 are mutually Cross arrangement. For the rest, referring to the structure and materials in Example 1, another flexible pressure sensor was obtained.

[0041] The flexible pressure sensor of this embodiment is tested by the same test method as in the above-mentioned embodiment 1. When the plurality of convex structures 112 in the flexible pressure sensor of this embodiment are subjected to an external pressure F, the following Figure 5 deformation shown. from Figure 5 It can be seen from the figure that although the convex structures 112...

Embodiment 3

[0043] This embodiment discloses the manufacturing method of the flexible pressure sensor in the above-mentioned embodiment 1, specifically refer to Figure 6-Figure 11 , the manufacturing method of the flexible pressure sensor according to the present embodiment includes the following steps:

[0044] Q1, select a substrate 41, and prepare a plurality of bumps 42 on the substrate 41; wherein, the shape and arrangement of these bumps 42 are the same as the shapes of the plurality of convex structures 112 in the flexible pressure sensor in Example 1 and arranged in the same way, such as Image 6 shown.

[0045] In this embodiment, the material of the substrate 41 is glass, and the material of the bumps 42 is polystyrene (abbreviated as PS); the shape of the bumps 42 is preferably spherical, and its particle size is controlled to be 100 nm to 1 mm. Preferably it is 20 μm.

[0046] Of course, the material of the substrate 41 can also be a silicon chip or a smooth plastic produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com