IC shearing bending forming machine

A technology of forming machine and bending mechanism, applied in shearing device, shearing machine equipment, metal processing machinery parts, etc., can solve the problems of unstable bending and forming production quality, affecting the formed quality, etc., and achieve good product consistency , The effect of convenient connection and combination operation, and the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

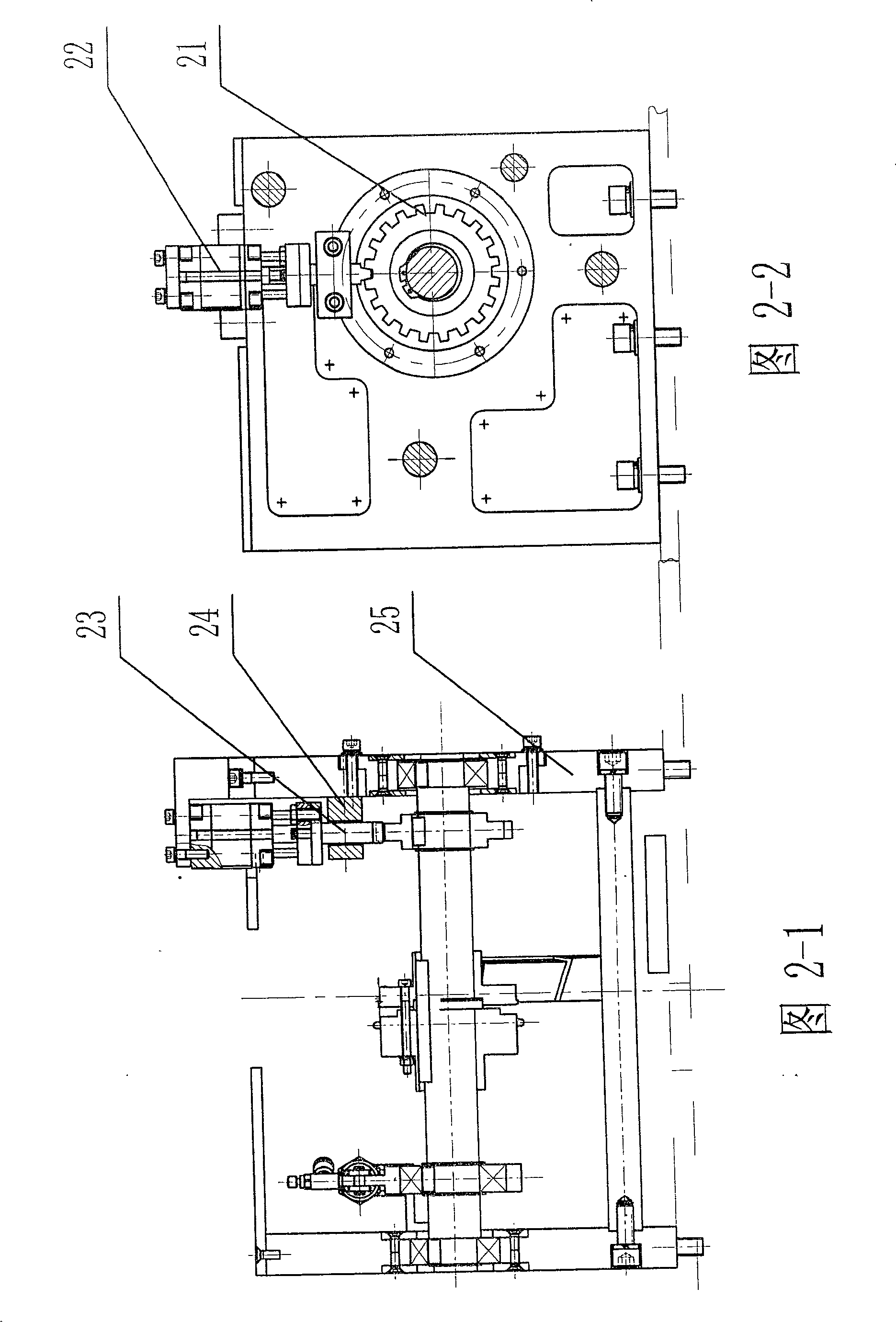

[0021] As shown in Figure 4, the present invention consists of a box material feeding device 1, an indexing positioning mechanism 2, a shearing and bending mechanism 3, a compression mold and a forming pressure wheel 4, a forming bottom knife 5, and a workbench 7, wherein:

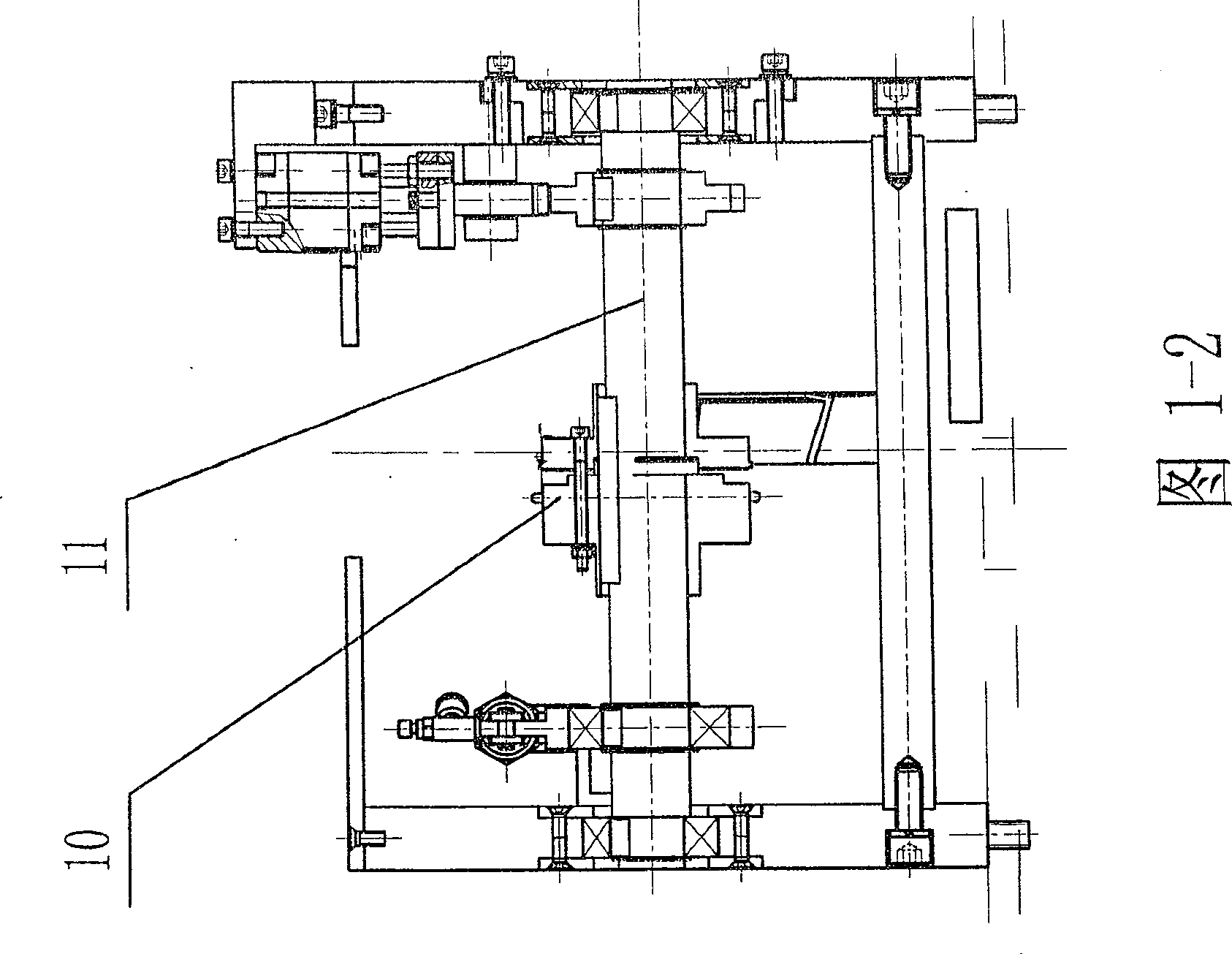

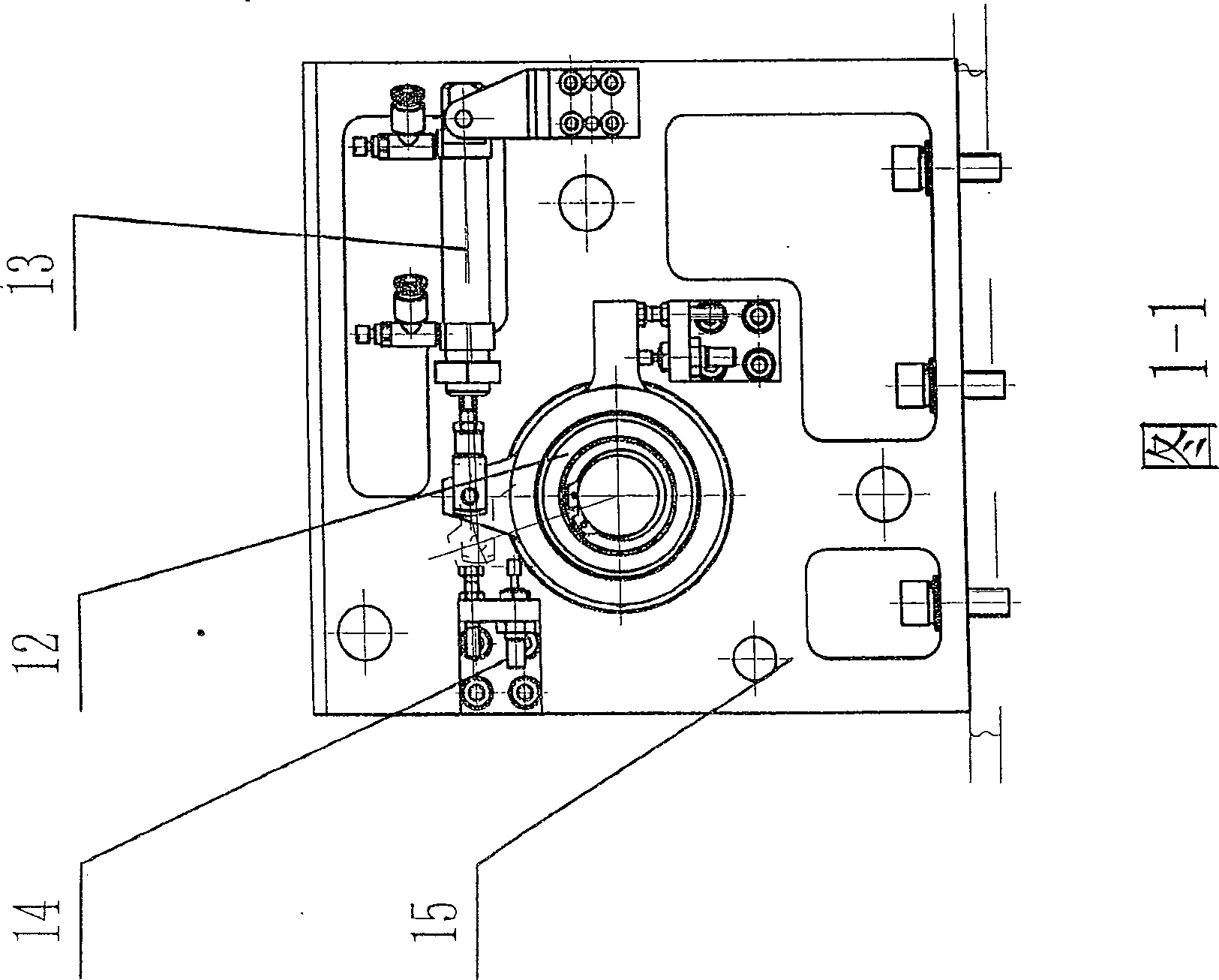

[0022] As shown in Figure 1-1 and Figure 1-2, the box material feeding device 1 is composed of a feed pulley 10, a main shaft 11, a one-way clutch device 12, a feeding cylinder 13, and a limit mechanism 14; The one-way clutch 12 fixes the hinge connection of the outer ring, the one-way clutch 12 is keyed to the main shaft 11, the limit device 14 is installed on the support plate 15, and the buffer and the limit screw on the limit device 14 can be adjusted to fix the outer ring. The circle defines the swing position of the one-way clutch device 12; the feed pulley 10 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com