Non wire drawing type electronic throttle control method

An electronic throttle and control method technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of short service life, easy damage, affecting the reliability and safety of the electronic throttle control system, and improve safety. and comfort effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

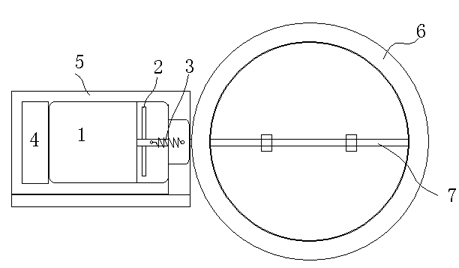

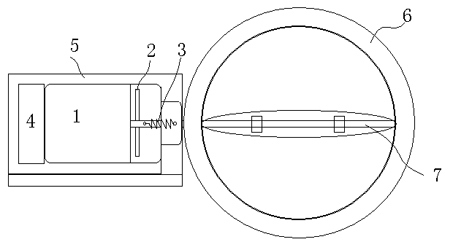

[0020] Such as figure 1 As shown, the cable-free electronic throttle control method includes at least: a motor 1, an angle sensor, a return spring 3, a controller 4, a throttle valve 6, a throttle control shaft 7 of the throttle valve 6, and a throttle valve of the throttle valve 6. The control shaft 7 is connected coaxially with the output shaft 10 of the motor 1, and the differential capacitive angle sensor 2 is connected between the throttle control shaft 7 and the output shaft 10 of the motor 1, and the two fixed electrodes of the differential capacitive angle sensor 2 The sheet 9 is fixed to the housing 5, and a moving electrode sheet 8 of the differential capacitive angle sensor 2 is fixed to the output shaft 10 of the motor 1. After the controller 4 receives the throttle control command, it The capacitance control motor 1 of the capacitive angle sensor 2 makes the throttle control shaft 7 rotate, as figure 2 shown.

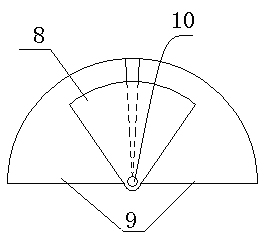

[0021] Such as image 3 with Figure 4 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com