Constant-speed universal coupling

A technology of universal joints and shaft couplings, which is applied in the direction of shaft couplings, elastic couplings, mechanical equipment, etc., can solve the problems of small angle, complex structure, large radial size, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

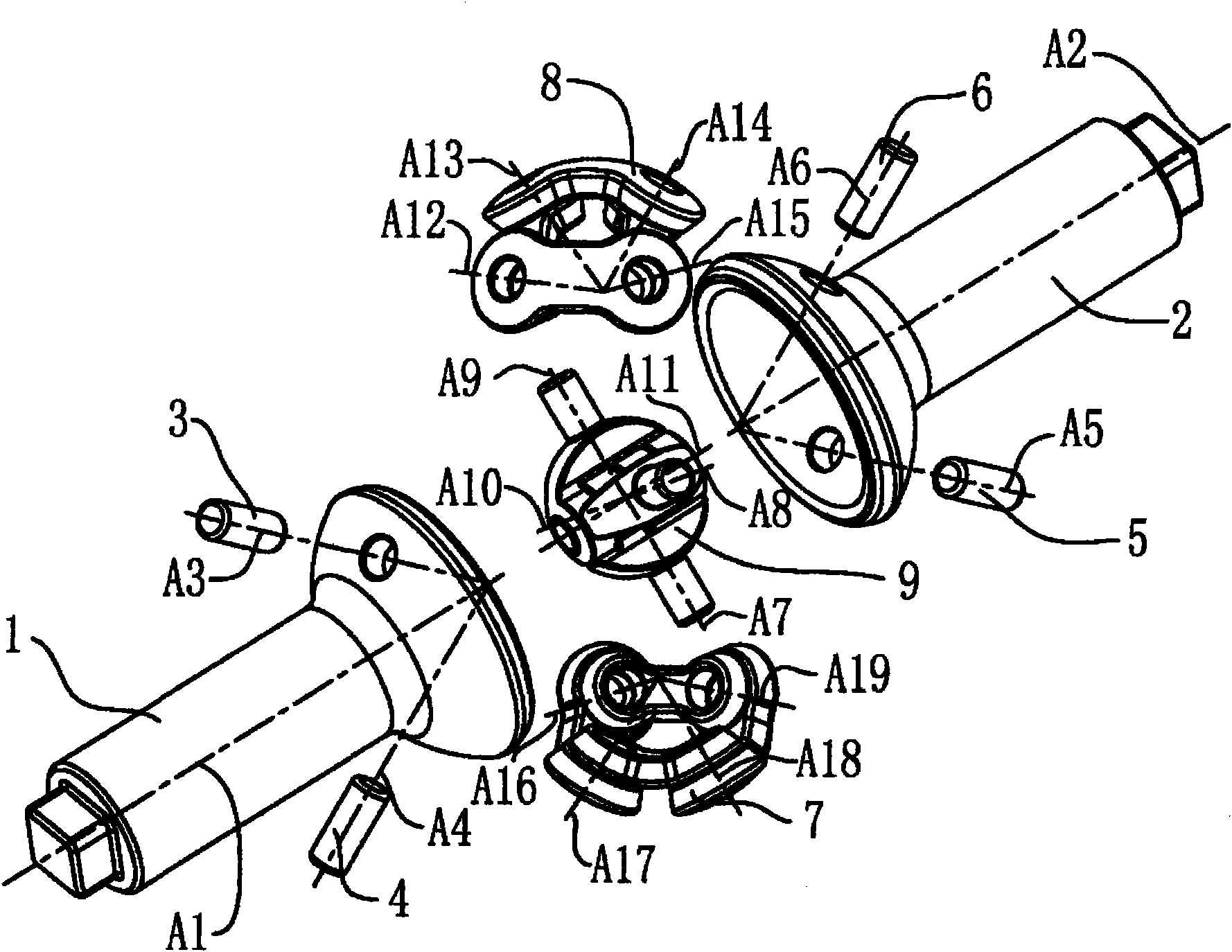

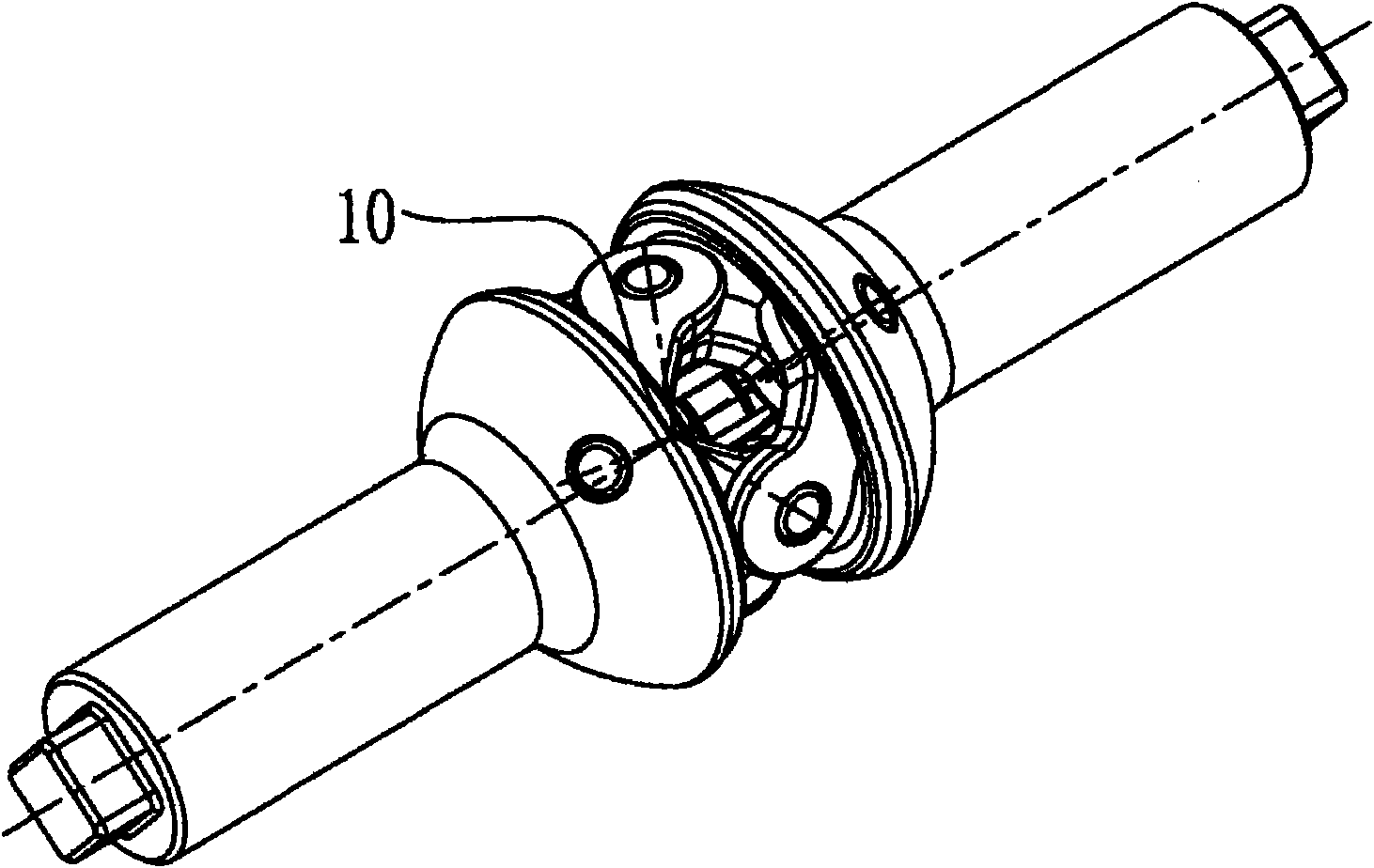

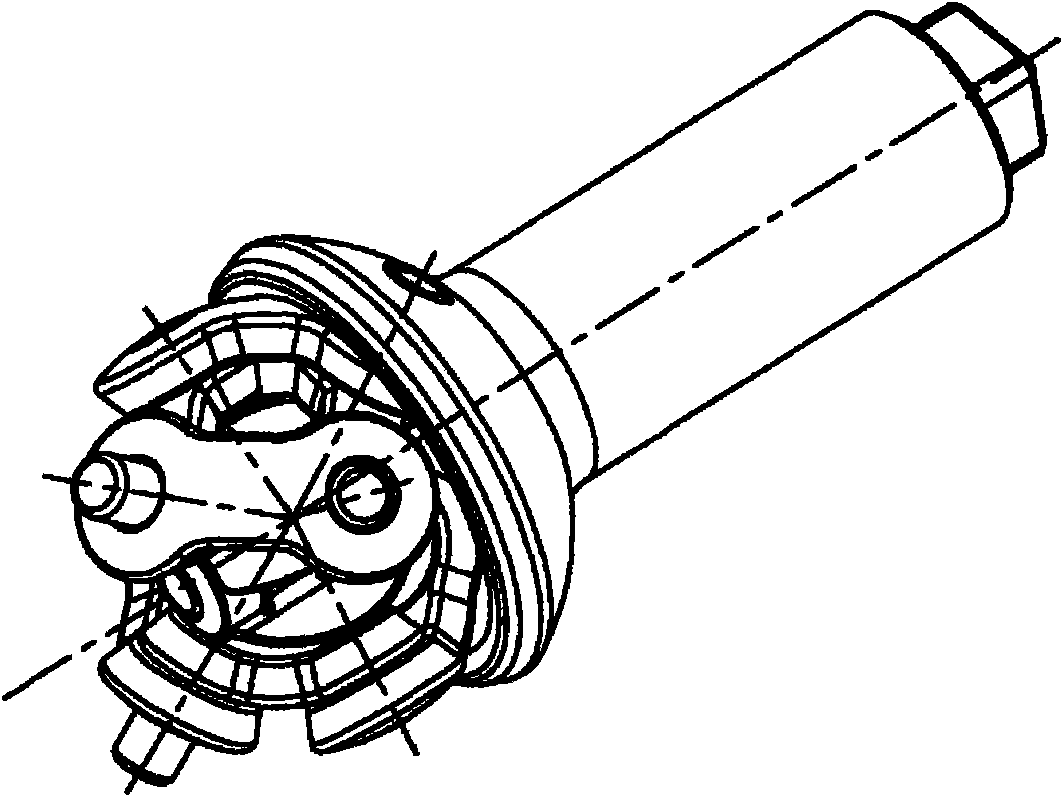

[0050] Four embodiments of the present invention will be described below. The constant speed transmission referred to in this manual means that the instantaneous rotational speed of the main and driven shafts of the coupling is equal at any moment. Figure 5 It is a brief diagram of terms related to the present invention, wherein the supplementary angle bisector (83) between the driving shaft (80) and the driven shaft (81) is defined as: between the driving shaft (80) and the driven shaft (81) The angle bisector of the supplementary angle (85) of the included angle (84). The plane of symmetry (82) between the driving shaft (80) and the driven shaft (81) is defined as: the plane that can make the driving shaft (80) and the driven shaft (81) symmetrical. The slewing pairs of all embodiments in the accompanying drawings in this specification are sliding friction. In order to realize pure rolling transmission, rolling bearings can be used in these slewing pairs, such as ball bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com