Valve plate driving mechanism of sealing cavity

A technology for sealing the cavity and driving mechanism, which is applied in the direction of engine components, sliding valves, valve details, etc., can solve the problems of complex parts processing, operation and maintenance, complex structure of the worm gear valve plate driving device, and high equipment configuration costs, and achieve The effect of low equipment configuration cost, easy implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

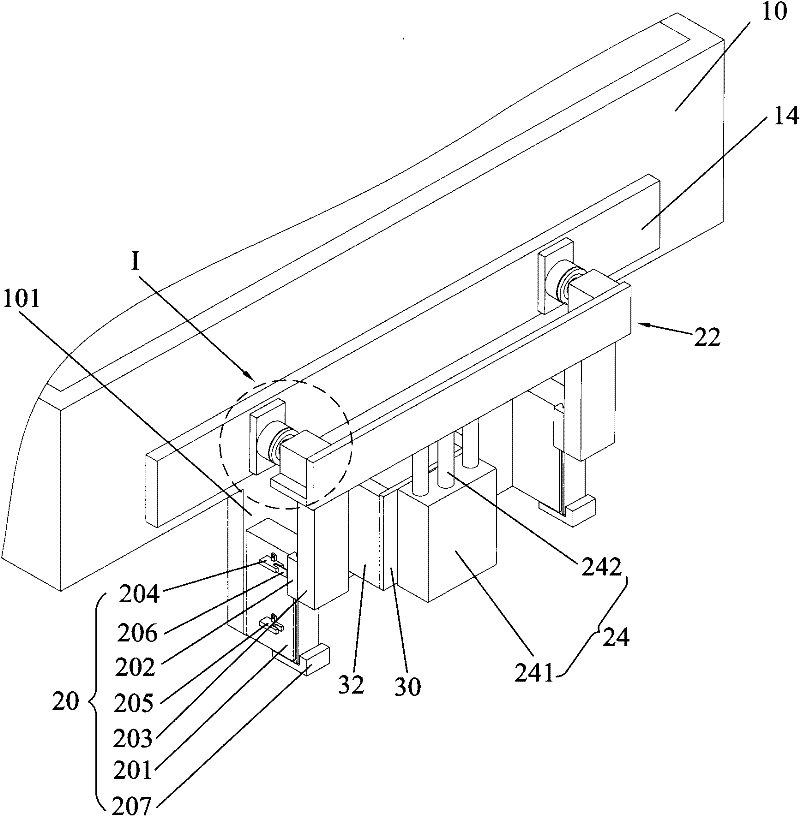

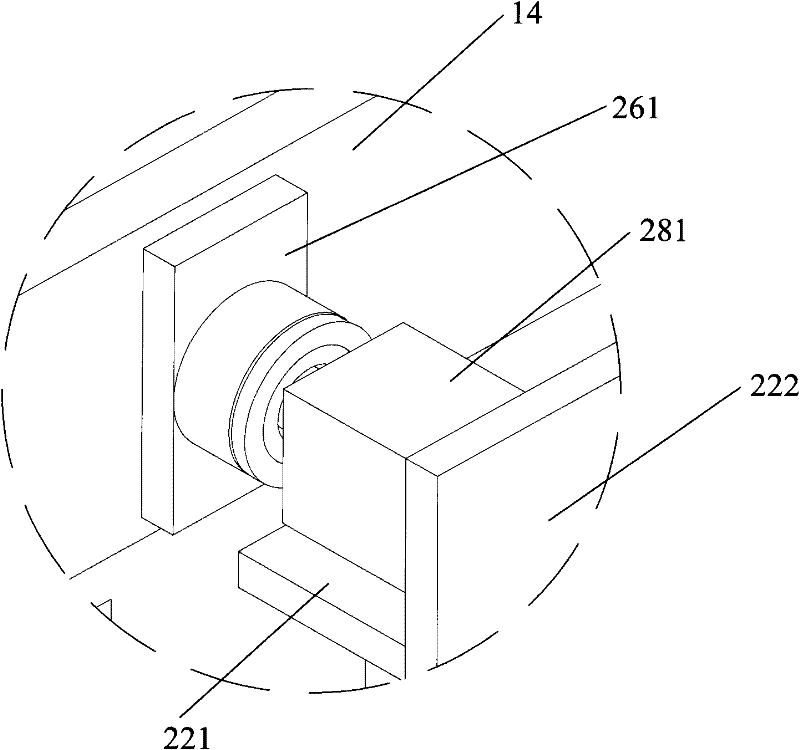

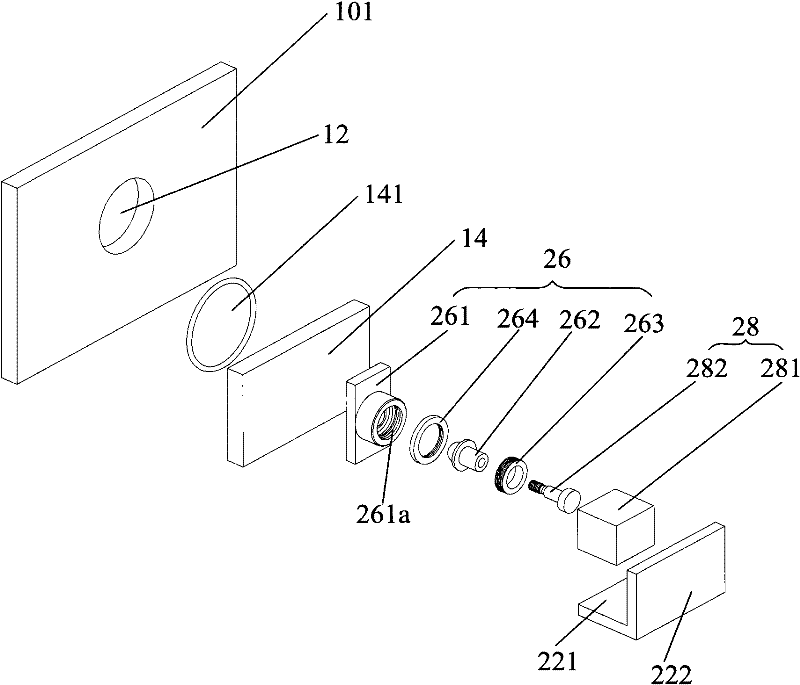

[0024] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a valve plate driving mechanism for a sealed cavity. Since the first driving device of the valve plate driving mechanism for a sealed cavity of the present invention drives the valve plate to perform longitudinal linear reciprocating motion through the mounting plate, The second driving device drives the valve plate to perform horizontal linear reciprocating motion, thereby realizing the process of the valve plate opening or closing the transmission window of the sealed cavity. The structure is simple and compact, and the movement is flexible and light. The processing, operation and maintenance are relatively simple, easy to implement, and the equipment configuration cost is low.

[0025] Please refer to Figure 1-3 , the sealing cavity valve plate driving mechanism of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com