Substation equipment appearance abnormality recognition method based on substation inspection robot

An inspection robot, anomaly recognition technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve problems such as large impact on image quality, human injury, inconsistent position, etc., and achieve the effect of robust illumination changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

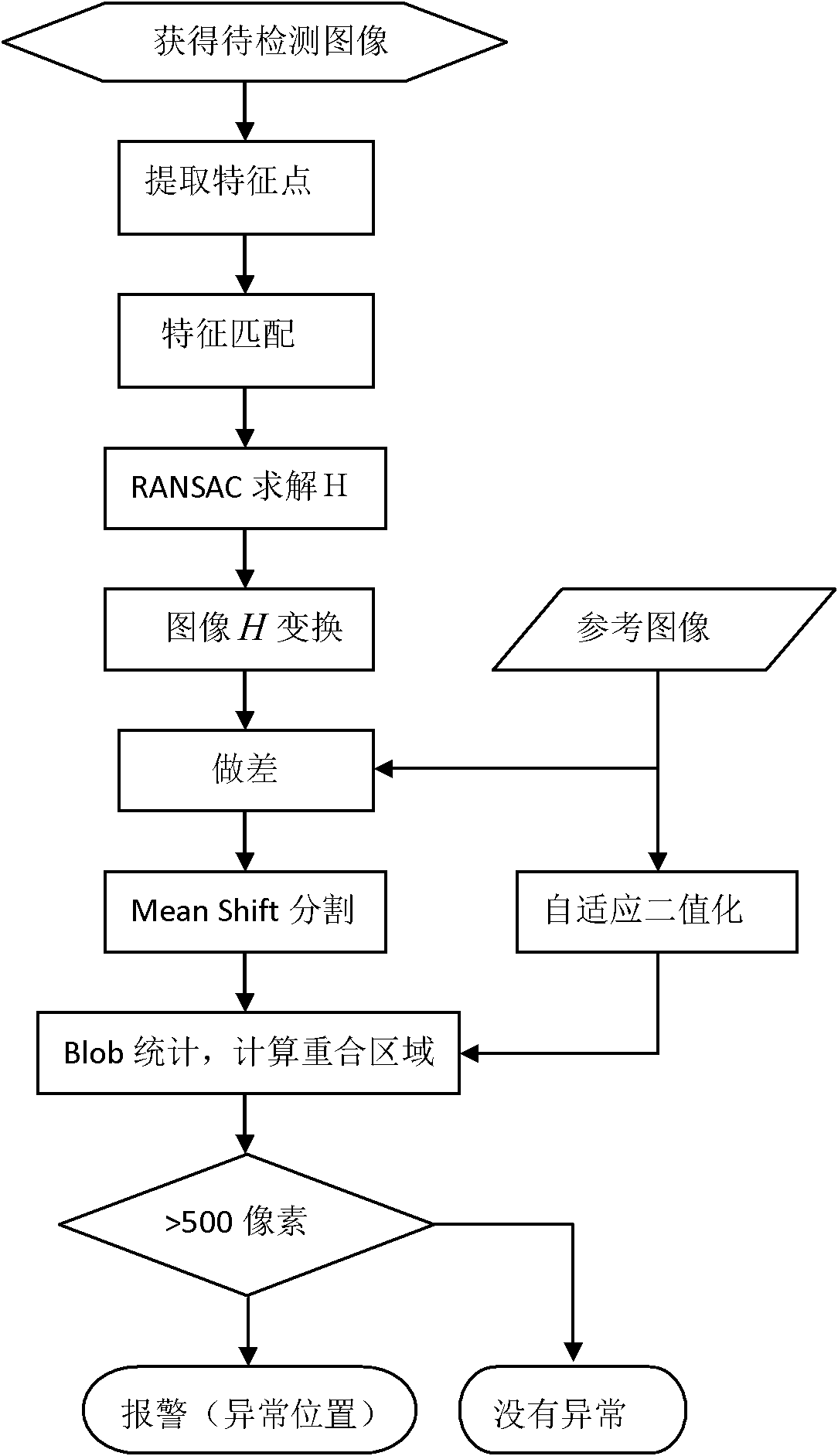

[0036] Figure 1-Figure 8 In, the steps of the present invention are:

[0037] 1) The power inspection robot collects the images of each equipment on the inspection route;

[0038] 2) Register the processed image with the corresponding device reference image stored in advance;

[0039] 3) After image registration, according to the difference between the two images, detect the abnormal region;

[0040] 4) Anomaly classification, classifying the anomalies according to the characteristic parameters of the detected abnormal regions.

[0041] In the step 1), the power inspection robot collects the current image at a fixed point on the option line, and stores it; as figure 2 , image 3As shown in , the images of the current transformer (CT) taken at different times are given, which are different in location and lighting conditions.

[0042] In the step 2), aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com