Electric tool

A technology of electric tools and tool heads, which is applied in the direction of manufacturing tools, metal processing equipment, portable drilling rigs, etc., can solve the problems of complex structure and high cost of the gearbox, and achieve the effect of simplifying the rear gearbox and reducing the number of stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions and other beneficial effects of the present invention will be apparent through the detailed description of specific embodiments of the present invention below in conjunction with the accompanying drawings.

[0021] The following will combine Figure 1 to Figure 3 Embodiments of the present invention will be described. Understandably, the electric tool of the present invention may be an electric drill, electric hammer, electric saw, electric planer, electric wrench and the like. To simplify the description, an electric drill is taken as an example below.

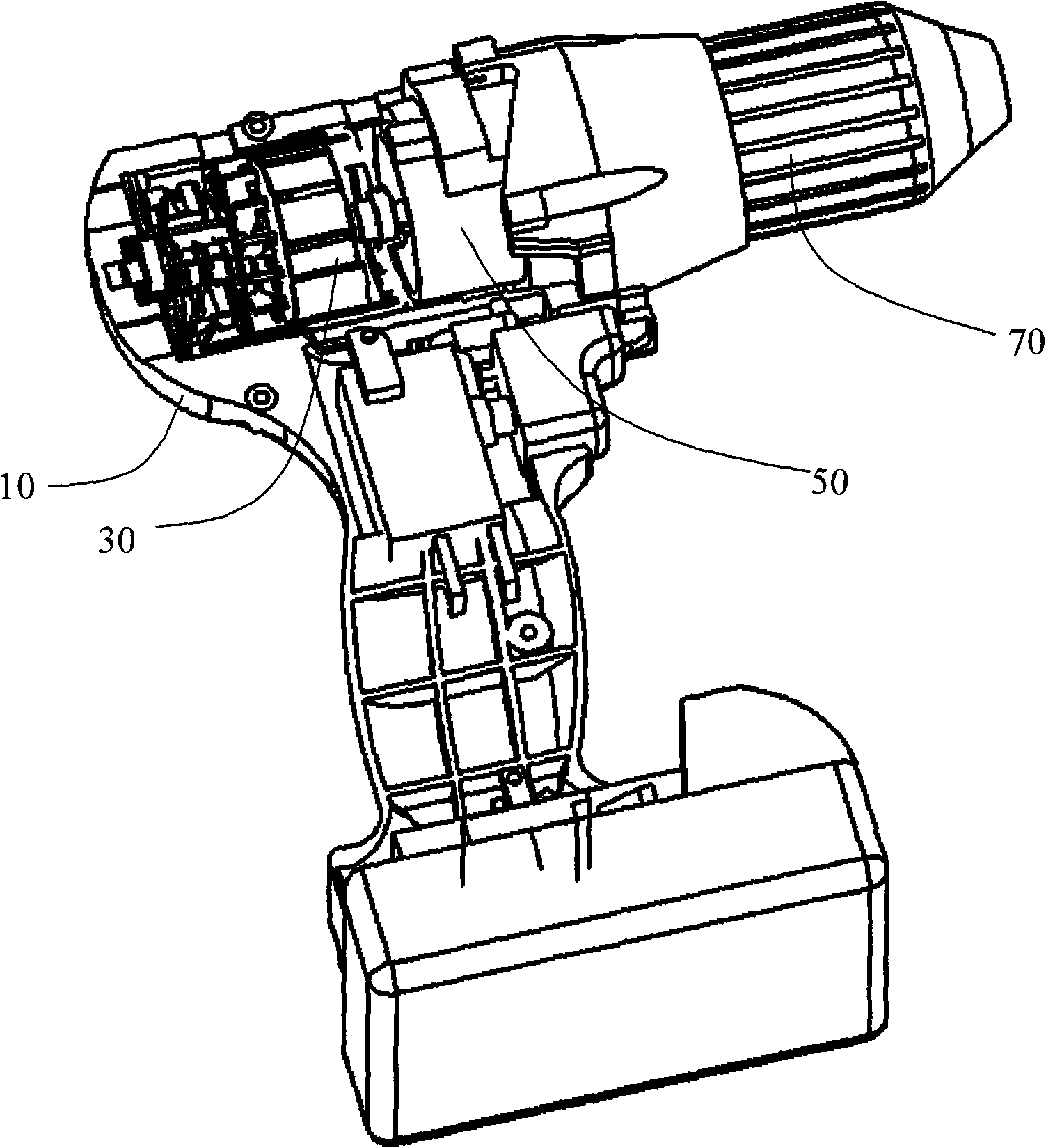

[0022] see figure 1 , the electric drill includes a housing 10, a motor 30 installed in the housing 10, a reduction mechanism 50 connected to the output shaft 32 of the motor, and a drill bit 70 driven by the reduction mechanism.

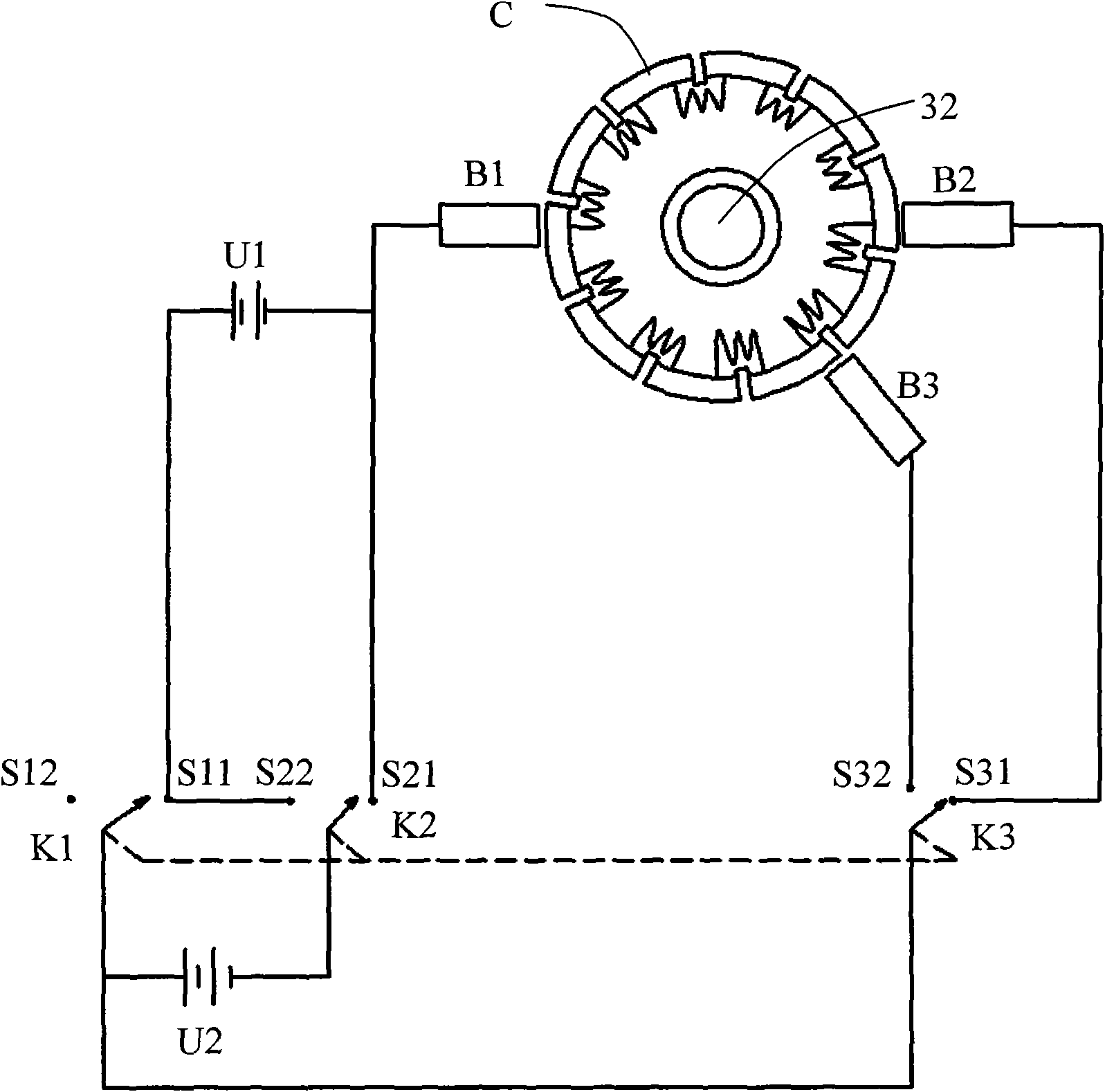

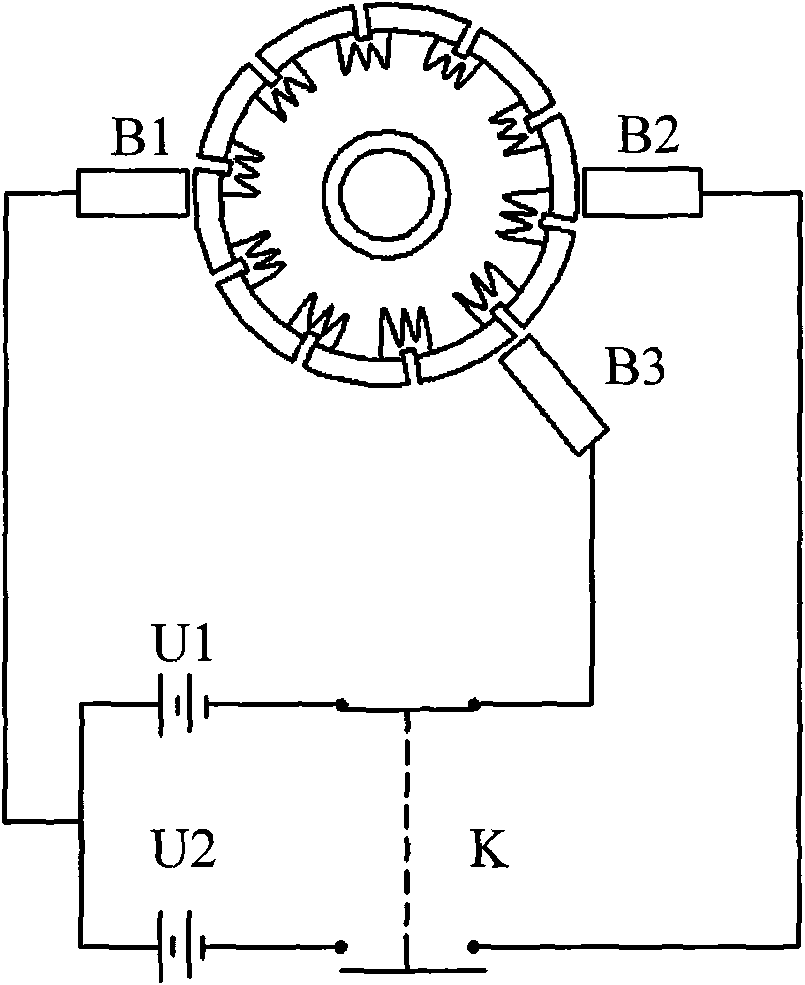

[0023] see figure 2 , the motor 30 is a DC motor, including a commutator C installed on the motor output shaft 32, a shared carbon brush B1, a low-speed carbon b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com