Method for blanking two-sided oblique head structural steel

A type of steel and double-sided technology, which is applied in the field of double-sided oblique head section steel blanking, can solve the problems of not being able to obtain double-sided oblique heads, and achieve the effects of large butt joint gaps, improved production efficiency, and accurate angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

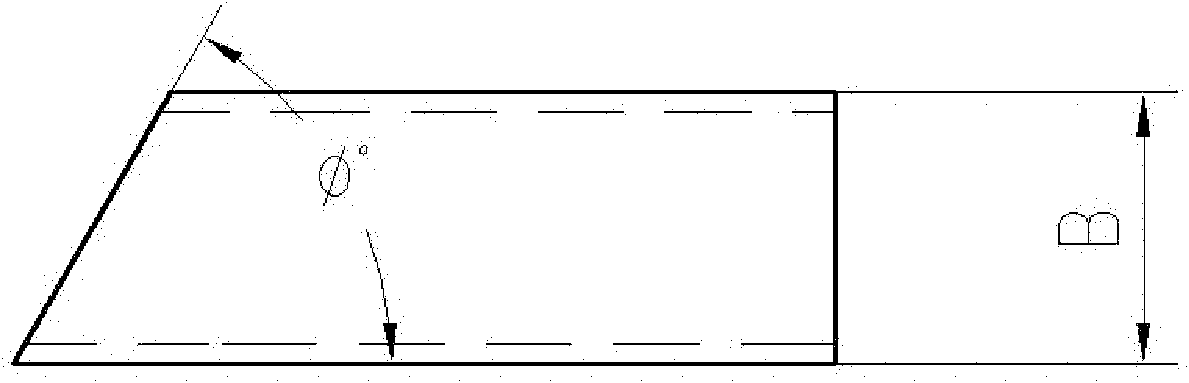

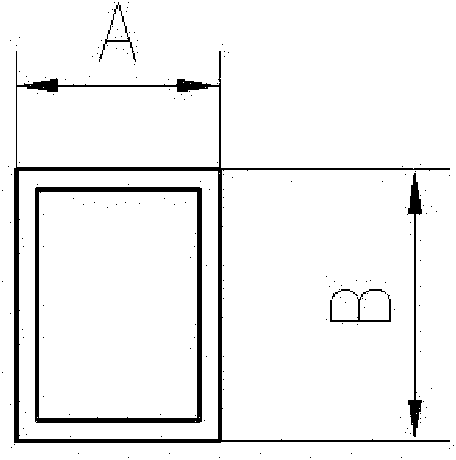

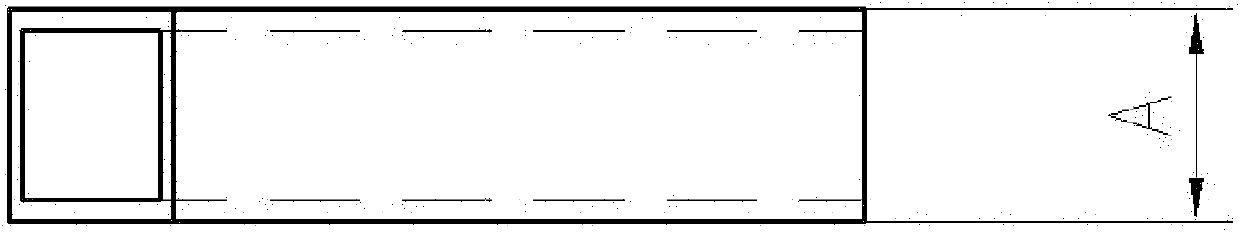

[0026] Such as Figure 4-12 As shown, a is the angle between the inclined plane of the profiled steel and the vertical plane, b is the angle between the inclined plane of the profiled steel and the horizontal plane, and both a and b are known quantities during actual processing, A is the height of the profiled steel, B is the width of the profiled steel, and X is the rotation of the profiled steel angle, is the rotation angle of the saw blade, and endpoint I, endpoint II, and endpoint III are the three endpoints of the spatial bevel head.

[0027] The blanking method of double-sided oblique head section steel includes the following steps:

[0028] 1). According to the rotation angle x of the profiled steel, the profiled steel base 5 is made; the profiled steel base 5 is made by opening a V-shaped groove with an included angle of 90° on the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com