Speed changer for full-automatic colorful carton box production line

A fully automatic, production line technology, applied in transmission boxes, instruments, transmission devices, etc., can solve the problems of inability to solve the relationship between the speed of the color carton production line, large cutting errors, and inability to determine the precise position of cutting, saving raw materials and fewer operators. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment for invention further description:

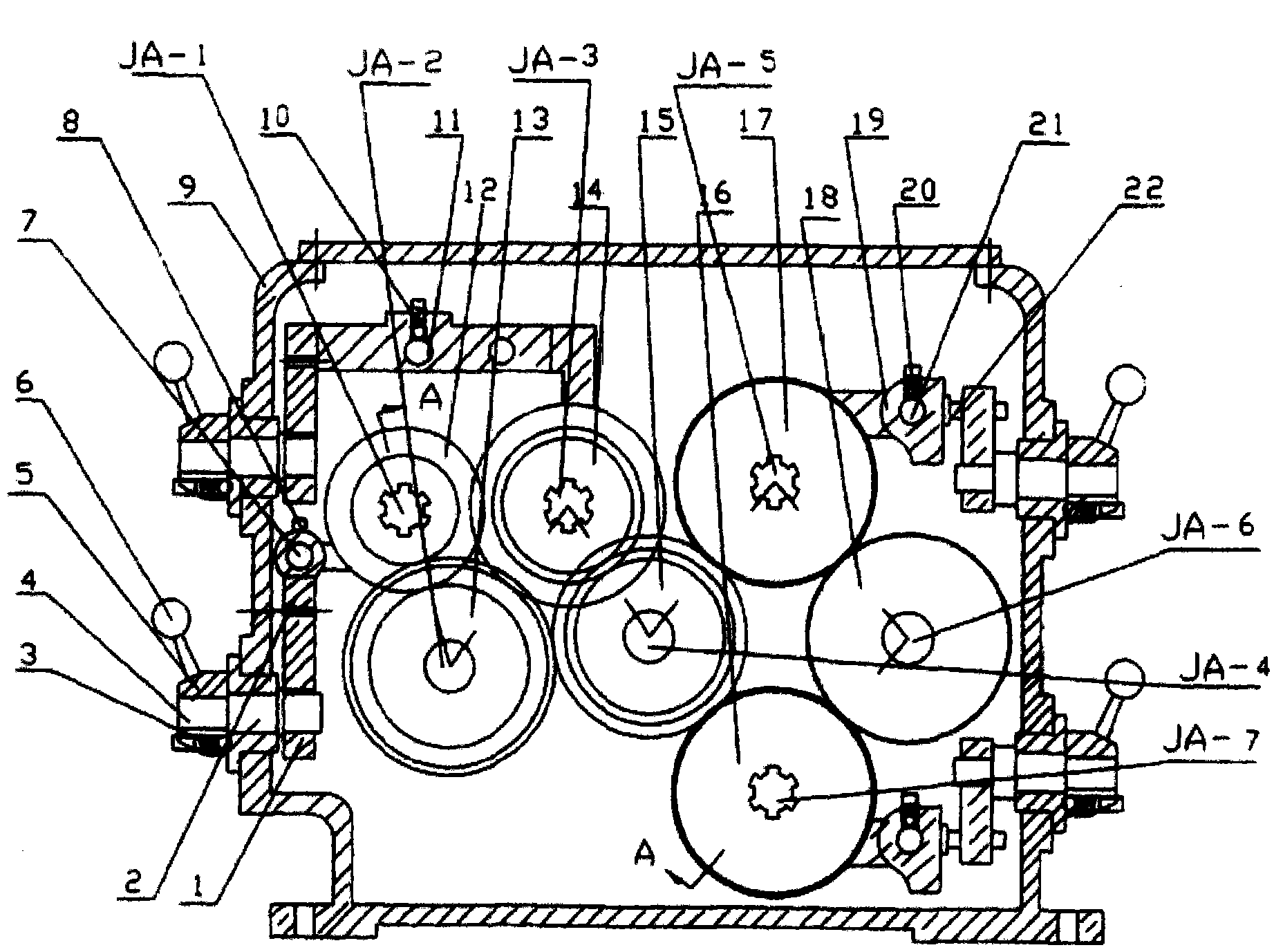

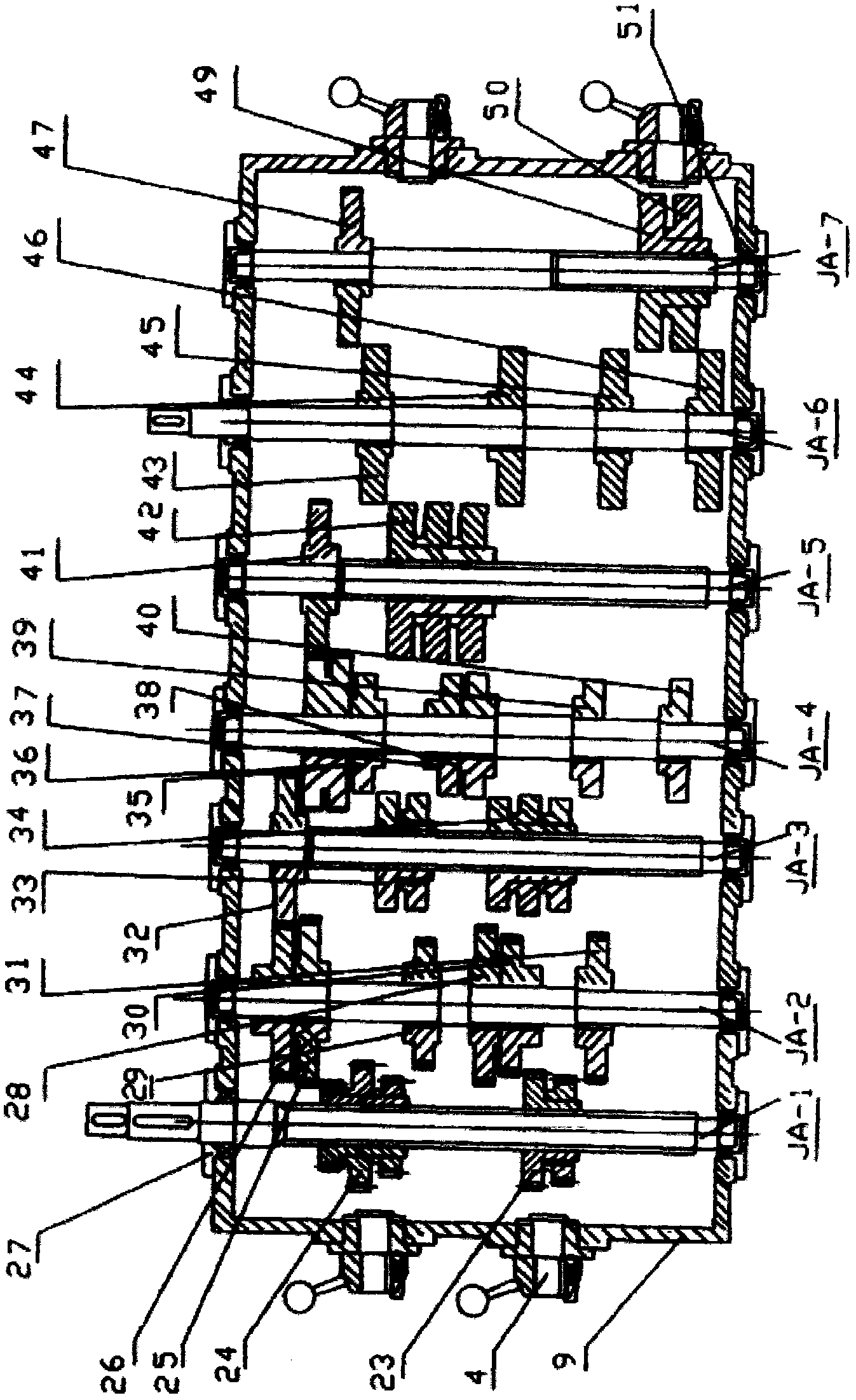

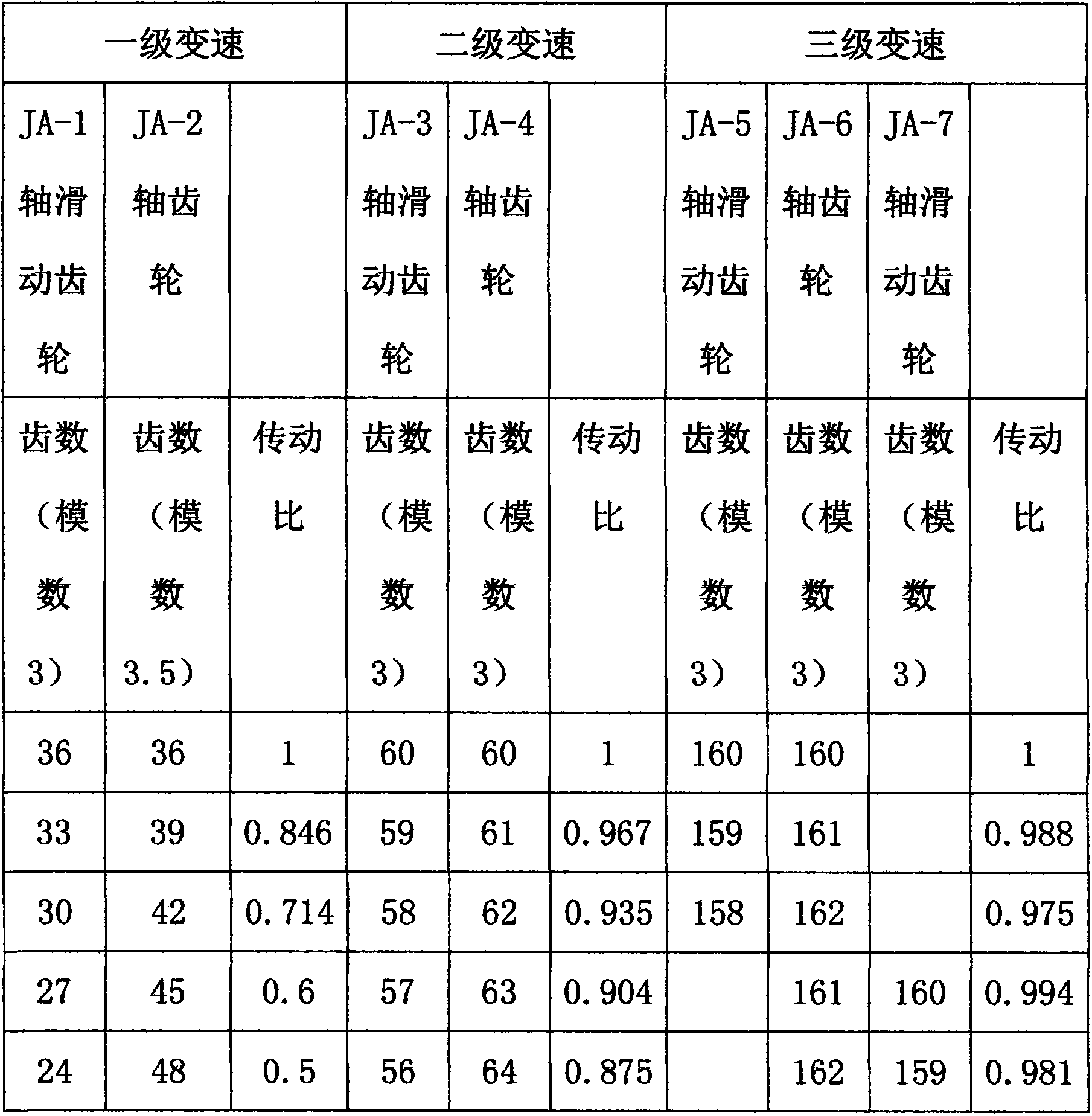

[0015] combine figure 1 , this embodiment includes a box body 9, a fork mechanism arranged on the outside of the box body, a positioning transmission mechanism connected to the fork mechanism arranged in the box body, and a speed change mechanism connected to the positioning transmission mechanism, wherein the speed change mechanism includes The tooth soft wheel shaft and the gear set, the gear sets 12-18 are arranged on seven shafts, each shaft is installed in the box body 9 through the bearing 51 and the bearing gland 27, and the seven shafts form a three-stage speed change, and each stage speed change includes Five groups of gears, one-stage speed change includes JA-1 and JA-2 shafts, two-stage speed change includes JA-3 shaft and JA-4, and one-stage speed change includes JA-5 shaft, JA-6 shaft and JA-7 shaft. There are four groups of the fork mechanism and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com