Trigger and tablet regulating mechanism

A technology for adjusting mechanisms and triggers, which is applied in the direction of nailing staple tools, nailing tools, manufacturing tools, etc., can solve the problems of difficult assembly and large accumulated errors, improve assembly efficiency, reduce assembly cost, improve work accuracy and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

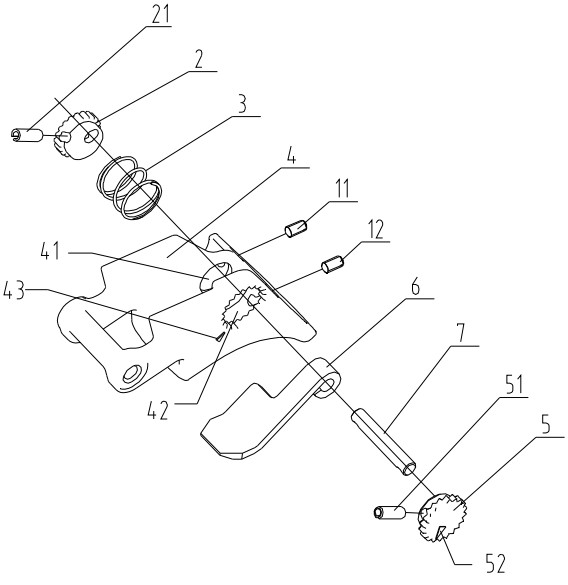

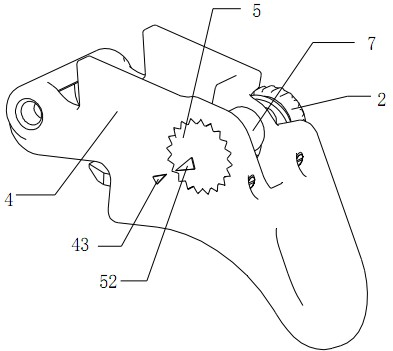

[0026] With reference to accompanying drawing, further illustrate the present invention:

[0027] The trigger pressing piece adjustment mechanism includes a trigger 4 and a pressing piece 6, the trigger 4 is hinged to the pressing piece 6, and the pressing piece 6 is located inside the trigger 4;

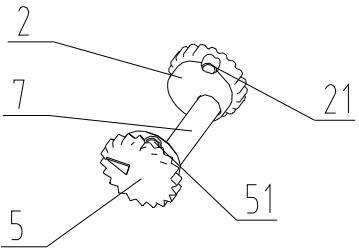

[0028] The two ends of the hinge shaft 7 between the trigger 4 and the pressing piece 6 are fixed respectively with an adjustment knob 2 that can drive the rotation of the hinge shaft 7 and an adjusting disc 5 that rotates with the hinge shaft 7 to adjust the height position of the pressing piece 6 ;

[0029] The connecting portion between the hinge shaft 7 and the adjusting knob 2 deviates from the center of the knob 2, and the connecting portion between the hinge shaft 7 and the adjusting disc 5 deviates from the center of the adjusting disc 5;

[0030] An elastic member 3 is provided between the adjustment knob 2 and the pressing piece 6; the trigger 4 is provided with a first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com