Hand trolley

A truck and wheel technology, applied in the field of trucks, can solve the problems of difficult steering operation, high labor intensity, inflexible operation, etc., and achieve the effects of easy and convenient steering control, reduced labor intensity, and flexible control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

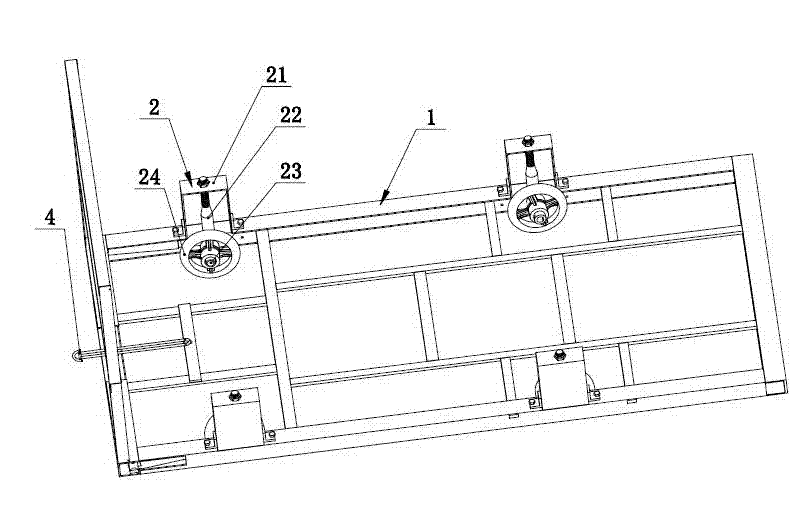

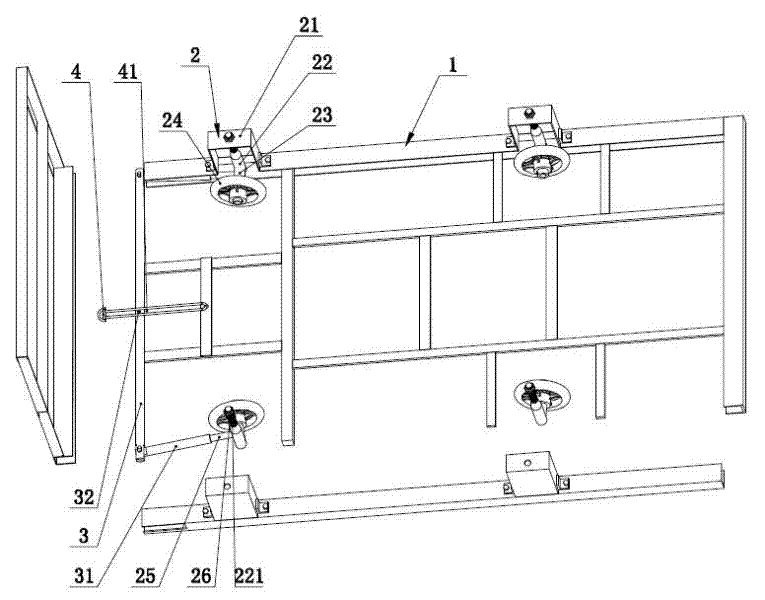

[0017] Such as Figure 1-2 The specific embodiment of the present invention shown includes vehicle frame 1, and described vehicle frame 1 is provided with four wheel mounting frames 2 distributed in a rectangular shape at four points, and each wheel mounting frame 2 includes a top beam 21, so The above-mentioned top beam 21 is liftably provided with a wheel elevating rod 22, and the wheel elevating rod 22 is fixedly provided with a wheel rotating shaft 23, and a wheel 24 is rotatably mounted on the wheel rotating shaft 23. In addition, in the present embodiment, any two left and right relative wheel mounting frames 2 are selected on the four wheel mounting frames 2, and the wheel rotating shaft 23 on the wheel mounting frame 2 is fixedly provided with a Inserting rod 25, the vehicle frame 1 is provided with a left and right moving rod 3 movable left and right, the length of the left and right moving rod 3 is adapted to the distance between two left and right relative wheel mou...

Embodiment 2

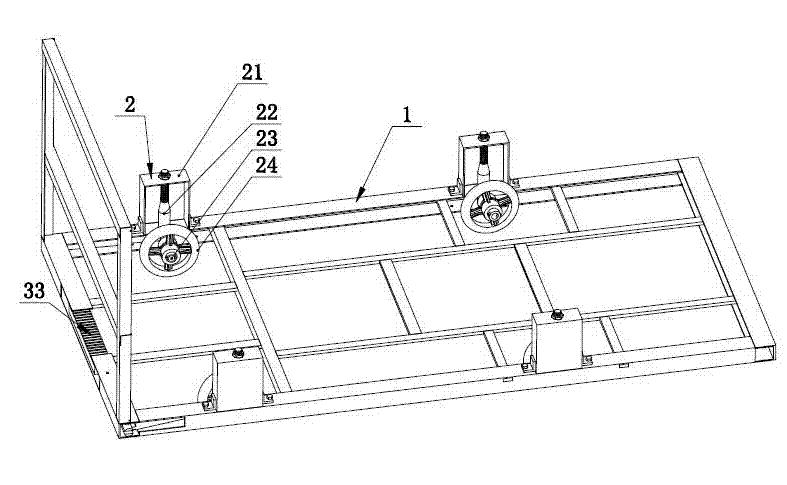

[0022] The difference between this embodiment 2 and embodiment 1 is that the left and right movement control of the left and right moving rod 3 is realized in this way: the left and right moving rod 3 is provided with bar teeth 33, and the described vehicle frame 1 is provided with There is a steering control wheel interlocked with the bar teeth 33 . Through the meshing transmission of the steering control wheel and the bar teeth, the left and right moving rod 3 is driven to move left and right, thereby conveniently controlling the steering of the truck. In practical applications, the steering control wheel can be coordinated with mechanisms such as motors, so as to realize the electrical control of the present invention. Since the meshing of the steering control wheel and the rack teeth 33 is a conventional technique well known to those skilled in the art, it will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com