Continuous multiple sputter coating chamber atmosphere isolation system

A sputtering coating and isolation system technology, which is applied in the field of vacuum coating, can solve the problems of increased manufacturing cost, mixing of working gas, and affecting the quality of coating, and achieve the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] The present invention will be described in further detail below with reference to the accompanying drawings.

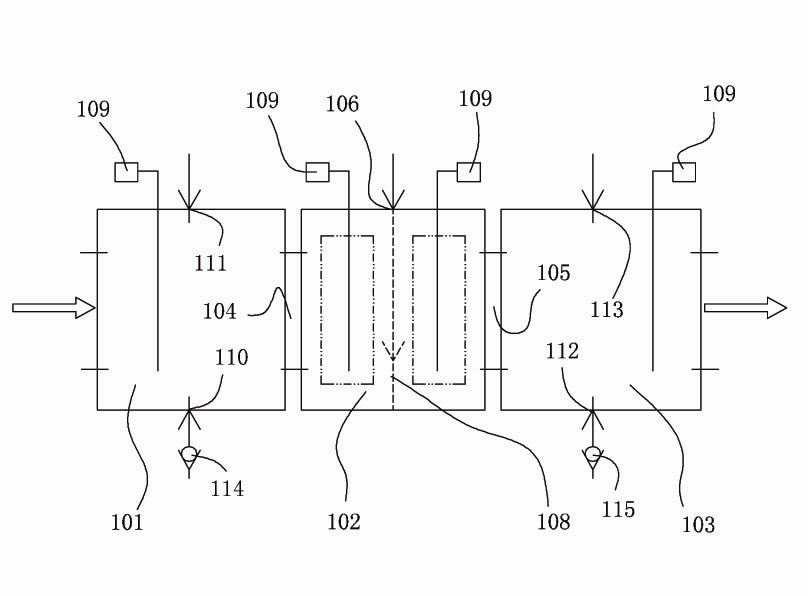

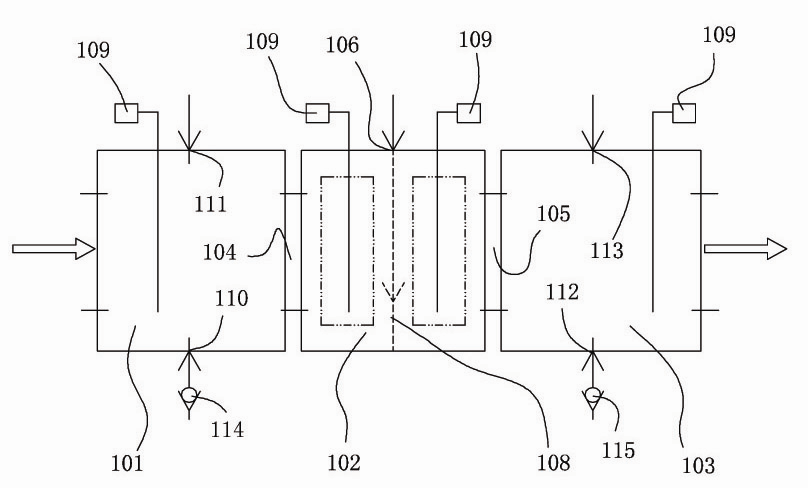

[0022] reference figure 1 , The first embodiment of the present invention is a continuous multi-chamber sputtering and coating room atmosphere isolation system, including two sputtering chambers, namely the first sputtering chamber 101 and the second sputtering chamber 103; The transition chamber 102 is arranged between the first sputtering chamber 101 and the second sputtering chamber 103; between the first sputtering chamber 101 and the transition chamber 102 is provided for plating The first channel 104 through which the object continuously passes, the transition chamber 102 and the second sputtering chamber 103 have a second channel 105 for continuous passage of the object to be plated; the transition chamber 102 is connected to a vacuum generator 109, so The vacuum degree of the transition chamber 102 is greater than the vacuum degree of the first sputtering ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap