Etching device and etching method

An etching device and etching technology, applied in the field of etching, can solve the problems of fast flow speed, fast update, uneven etching of circuit substrates, etc., and achieve the effect of consistent etching speed, same update speed, and avoiding pool effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The etching device and etching method provided by the present technical solution will be described in detail below in conjunction with the drawings and embodiments.

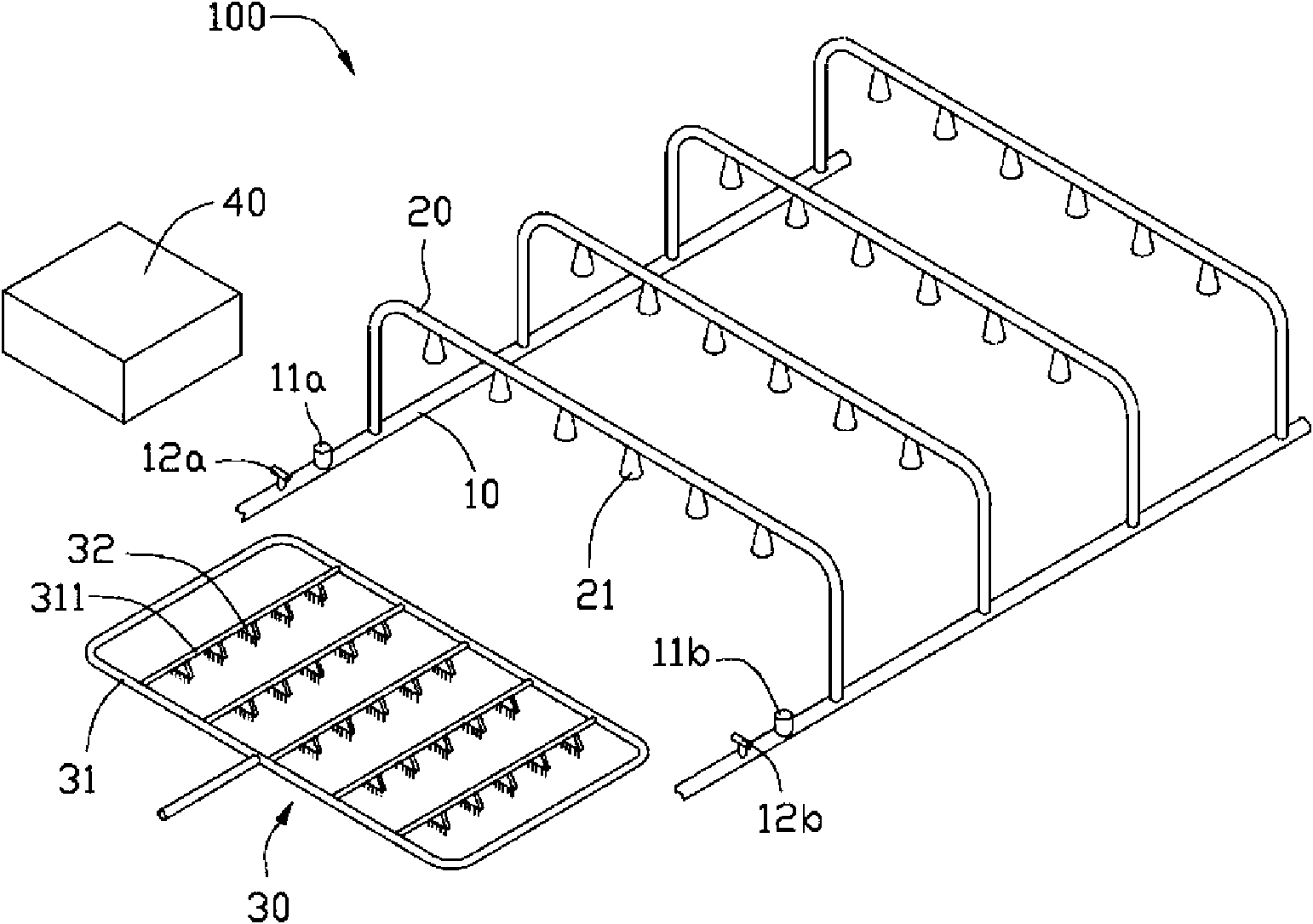

[0016] Refer to figure 1 The etching device 100 provided in the first embodiment of the technical solution includes two liquid infusion pipes 10, four nozzle pipes 20, pumps 11a, 11b, valves 12a, 12b, a liquid scraping device 30 and a control device 40.

[0017] The two infusion tubes 10 are opposite and arranged parallel to each other. Each liquid infusion tube 10 communicates with a liquid storage tank (not shown), and the etching liquid is delivered to the four nozzle tubes 20 through pumps 11a and 11b, respectively.

[0018] The four nozzles 20 are arranged parallel to each other, and the two ends of each nozzle 20 are respectively communicated with an infusion tube 10, so that the etching liquid can flow from the nozzle 20 through the infusion tube 10 from the liquid storage tank. Each nozzle 20 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com