Blowing tube material returner used for circulating fluidized bed boiler

A circulating fluidized bed and blowing pipe technology, which is applied in the field of circulating fluidized bed boilers, can solve the problems that fine ash cannot reach the dense phase area of the bed, increase the oxygen content of flue gas, and deviate from the scope of economic operation, and reduce the The effect of particulate pollutant emissions, lower production costs, and obvious competitive advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

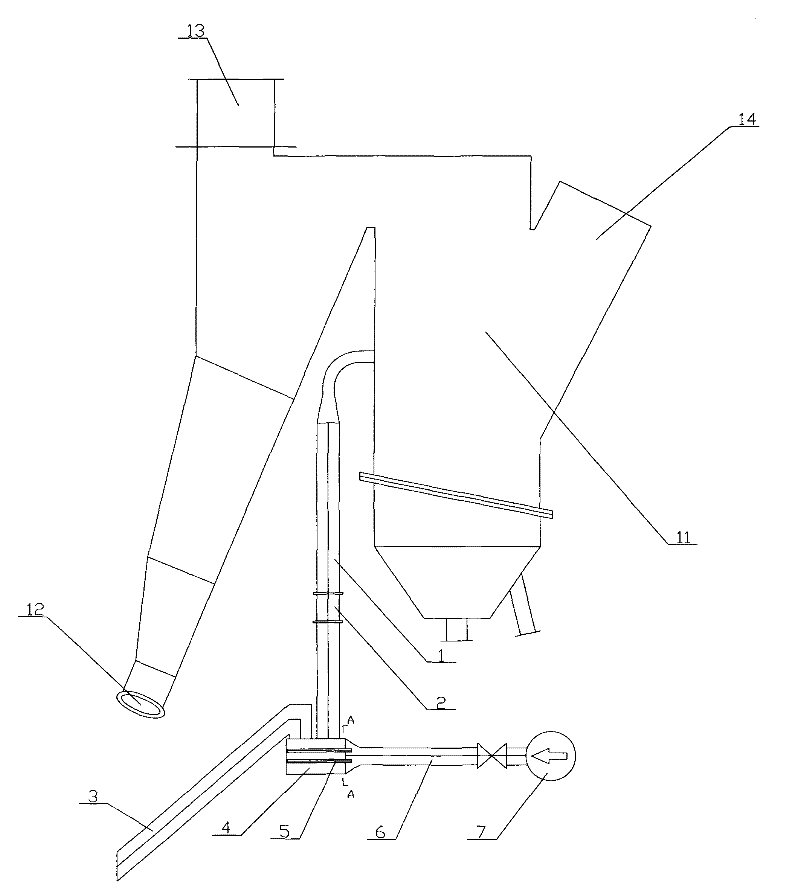

[0027] The structure of circulating fluidized bed boiler is as follows: Figure 9 , including boiler furnace 17, air cap 16, air chamber 15, separator 18, boiler flue 19, feeder 11 and scraper coal feeder 20, boiler furnace 17 is provided with air cap 16 and air chamber 15, separator 18 The upper part communicates with the boiler furnace 17 and the boiler flue 19 respectively, the lower part is connected to the return feeder 11 through the ash inlet pipe 14, the upper part of the return feeder 11 is connected to the scraper coal feeder 20 through the coal inlet pipe 13, and the return feeder 11 is also passed through the return feeder 11. The discharge pipe 12 of the feeder is connected to the furnace 17 of the boiler.

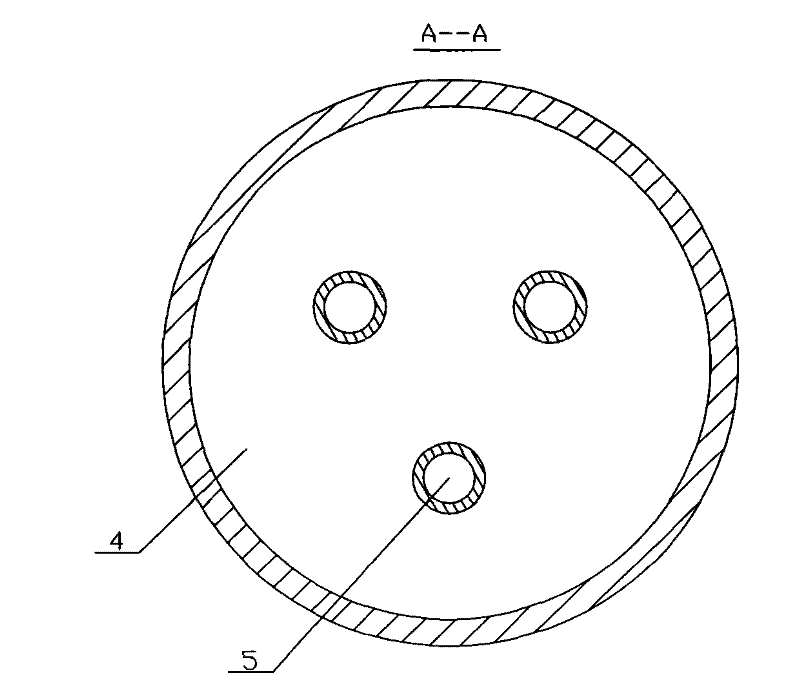

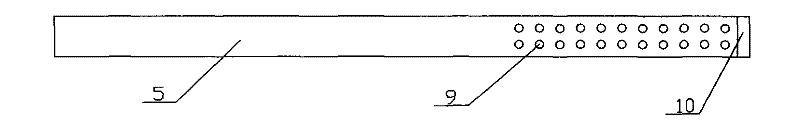

[0028] The structure of the injection pipe return device used in circulating fluidized bed boilers is as follows: figure 1 , consisting of feed pipe 1, expansion joint 2, discharge pipe 3, spray pipe return device 4, blow pipe 5, air intake pipe 6 and fan 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com