A kind of tial+ti 2 Method for preparing alnb composite material by laser melting deposition

A technology of laser melting deposition and composite materials, which is applied in the field of laser melting deposition preparation of TiAl+Ti2AlNb composite materials, can solve the problems of difficult release of stress, cracks, and difficulty in determining the plasticizing mechanism, so as to reduce thermal stress concentration, slow down the solidification speed and Cooling rate, effect of avoiding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and example:

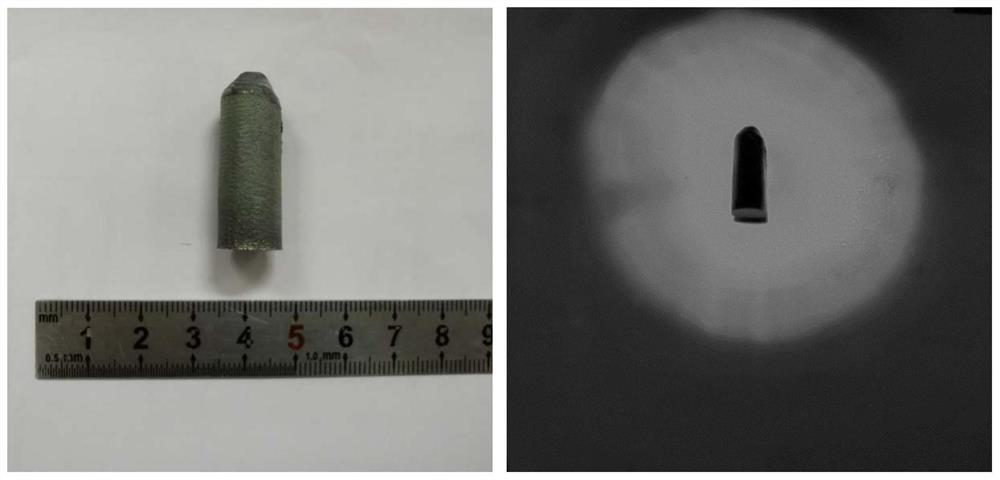

[0023] (1) The experimental equipment is Arnold 6KW three-dimensional laser processing and manufacturing system, and the raw materials used for laser melting deposition forming are spherical TiAl and Ti 2 AlNb powder, the powder particle size is 53-106μm, using dual-channel coaxial powder feeding, so that TiAl powder and Ti 2 AlNb powder is mixed into the molten pool at a volume ratio of 7:3, that is, the volume ratio of the two powder feeding channels is adjusted to be 7:3.

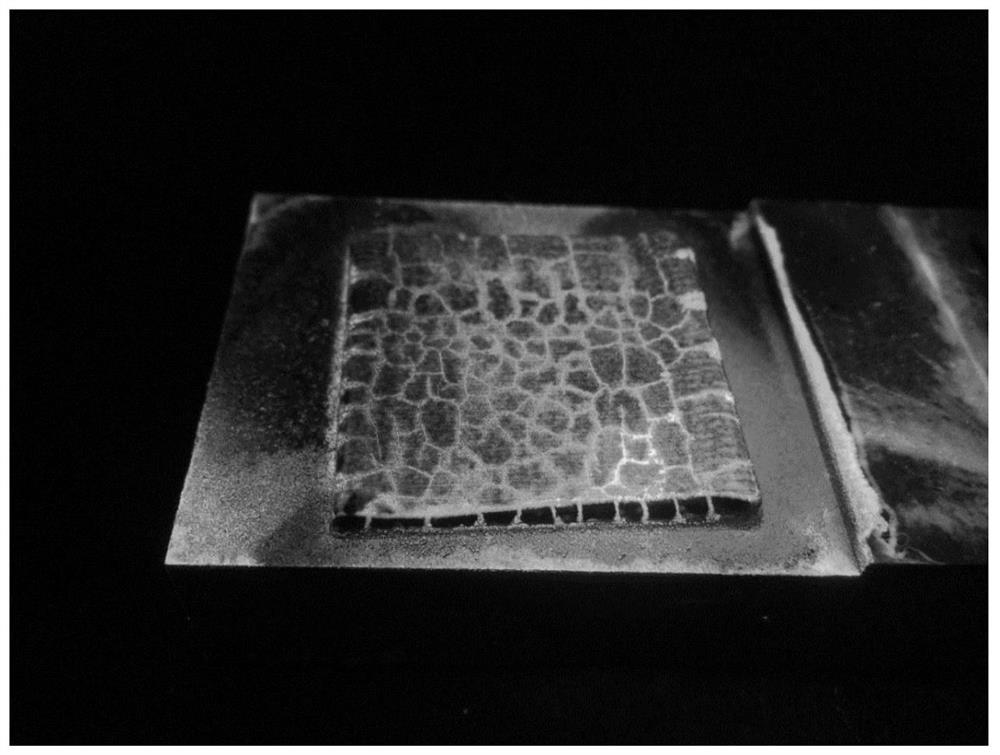

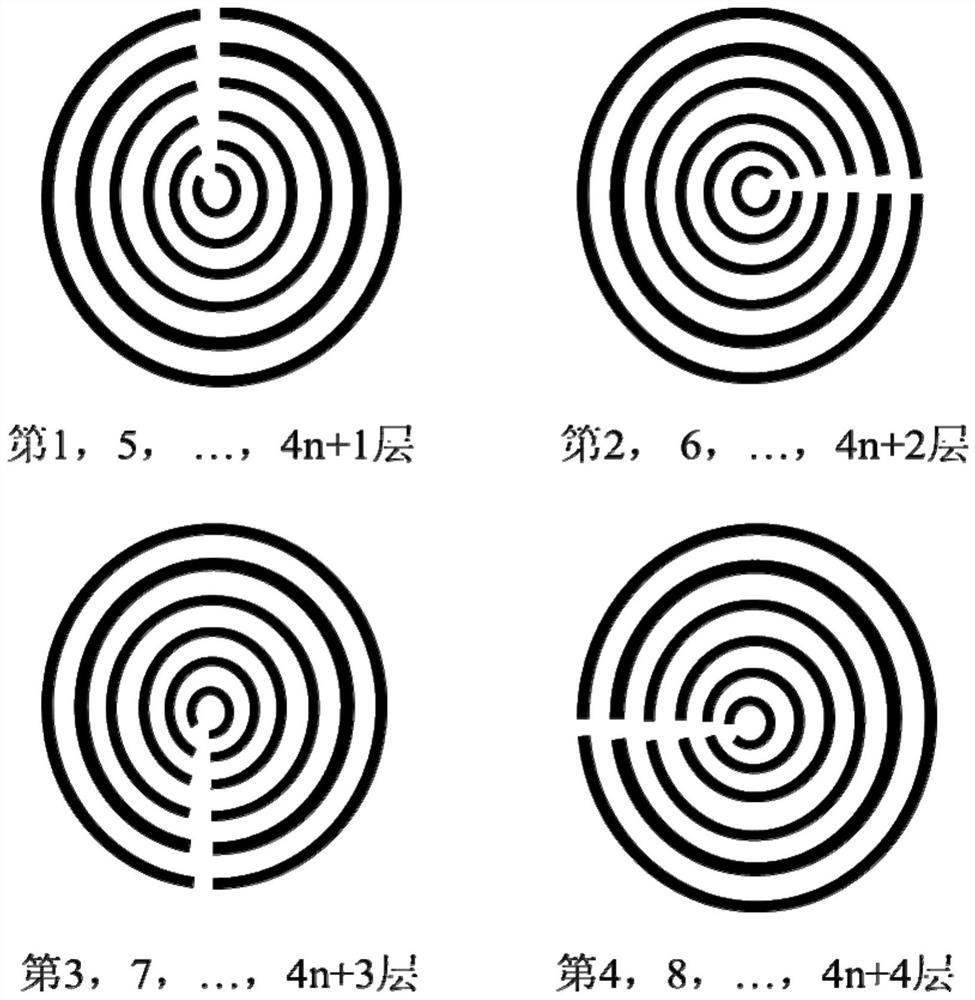

[0024] (2) The scanning path of the forming process is a concentric arc from the outside to the inside. The overlap distance between the concentric arcs is 0.7mm, and the radial overlap between the concentric arcs is 0.7mm (about 43 %), and the lap length of each concentric arc at the opening is 0.7mm. In each layer, the opening direction of each concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com