Middle seal preheating mechanism

A preheating device and rack technology, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve problems such as scalding products, and achieve the effects of increasing the contact area, uniform heating, and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

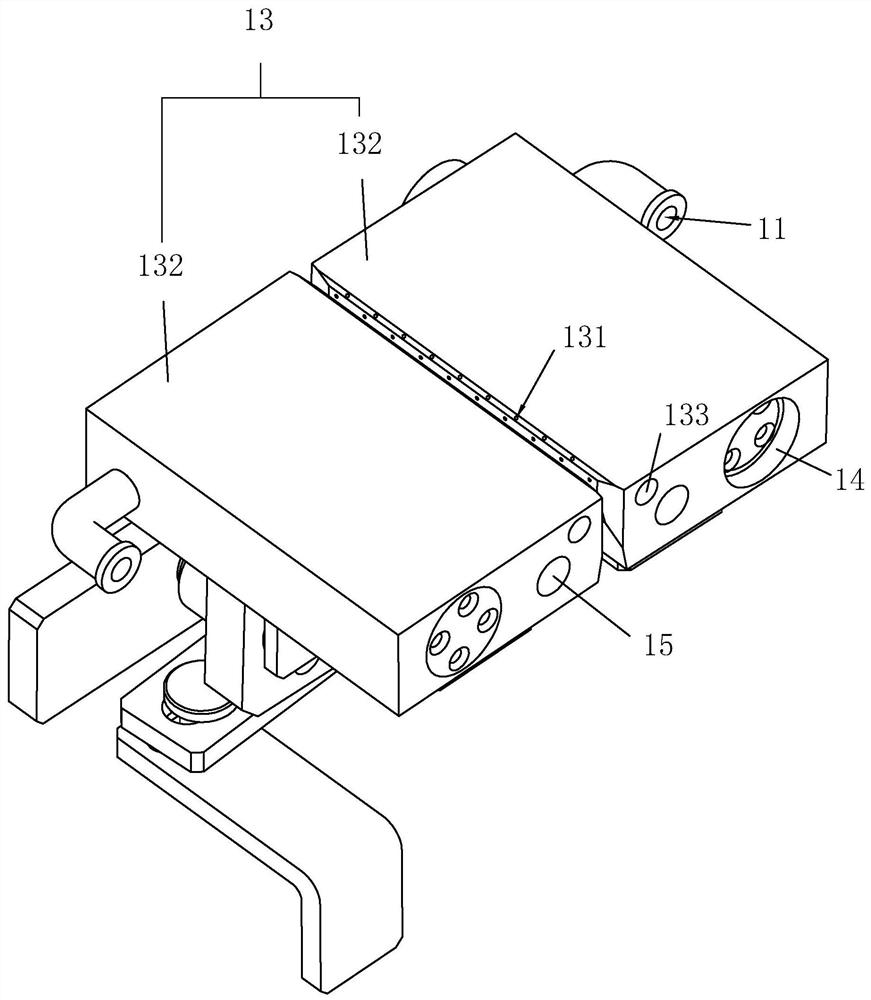

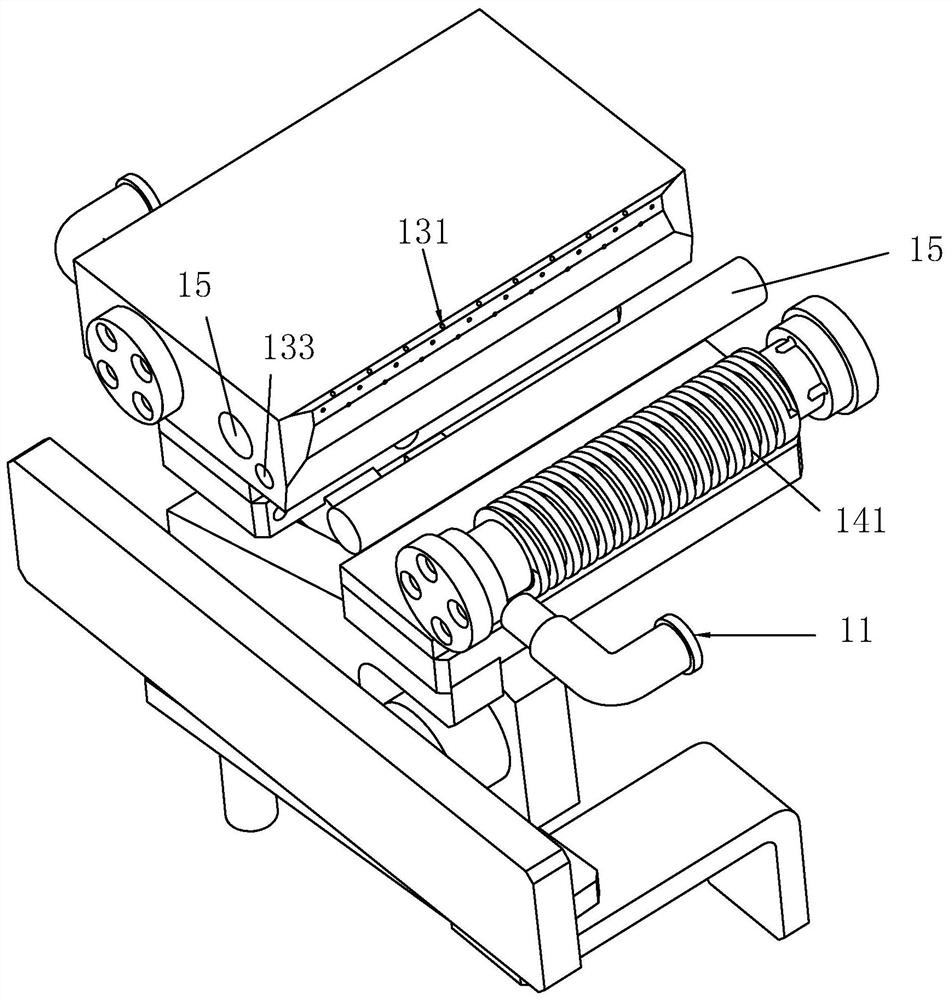

[0020] A middle sealing preheating mechanism, such as figure 1 As shown, a frame 1 is included, a preheating device is arranged on the frame 1, a workbench 13 is arranged on the frame 1, a heating gas outlet 131 is arranged on the workbench 13, and the preheating device includes a gas source input port 11 and a The heat conduction channel 14 connected to the gas source input port 11, the heat conduction channel 14 communicates with the heating gas outlet 131, and also includes the heating rod 15 arranged in the workbench 13; after the material to be packaged meets the film in the packaging machine, the film is to be packaged After the material is wrapped, it is then sealed. Before heat sealing, the preheating device is used to assist in heating the sealing part of the packaging material, so as to better complete the heat sealing package. When preheating, open the heating rod 15 to heat the workbench 13 , and then the air is input from the air source input port 11, and compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com