New transposition wire rigidity test device

A technology of transposition wire and rigidity test, which is applied in the direction of measuring device, testing material hardness, instrument, etc., to achieve the effect of simple structure and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

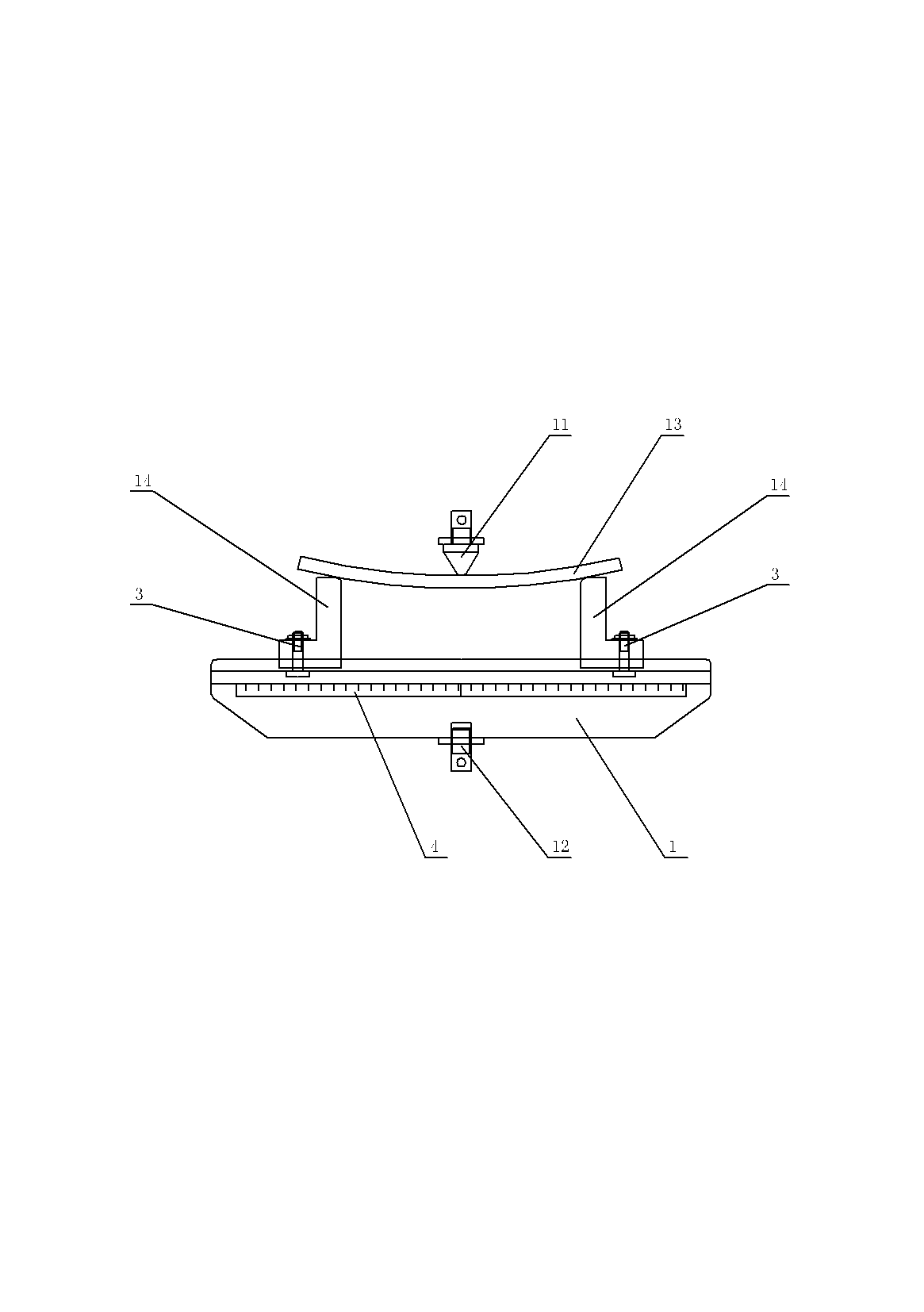

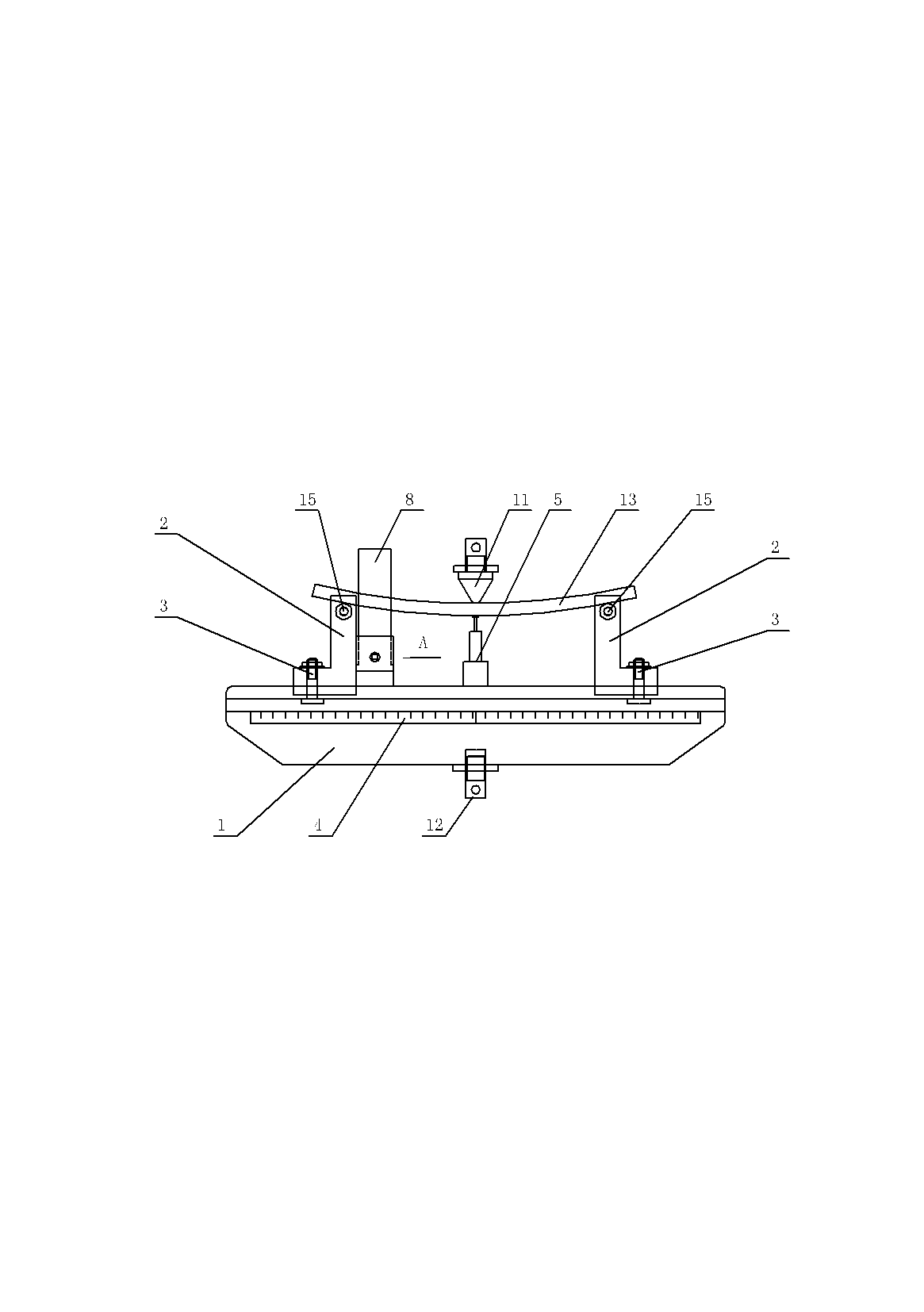

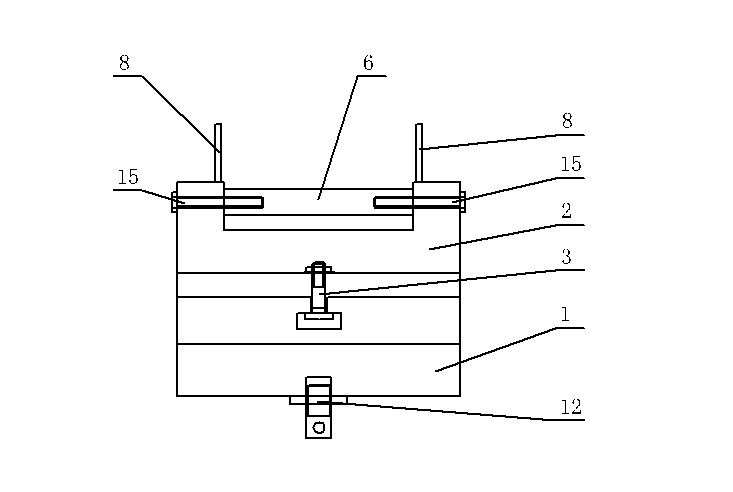

[0011] see figure 2 , image 3 with Figure 4 , The transposition wire rigidity test device of the present invention includes a base 1, a pair of L-shaped sliders 2 are installed transversely on the base 1, a pair of L-shaped sliders 2 are installed oppositely, and the L-shaped sliders 2 are fixed to the bottom plate 1 by bolts 3. A ruler 4 is installed on the side of the base 1, a pair of L-shaped sliders 2 can be moved to a specified interval according to the scale of the ruler, and a back-to-return sensor 5 is installed in the center of the base 1. A pair of L-shaped sliders 2 are equipped with longitudinal rollers 6; both ends of the longitudinal rollers 6 are fixed on the L-shaped slider 2 by nuts 15; the inner side of the single-sided slider 2 is equipped with a two-way stop mechanism; a two-way stop mechanism It includes a bottom plate 7 and a stopper 8; the bottom plate 7 is arranged longitudinally along the base 1, and is installed on the base 1 through positioning bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com