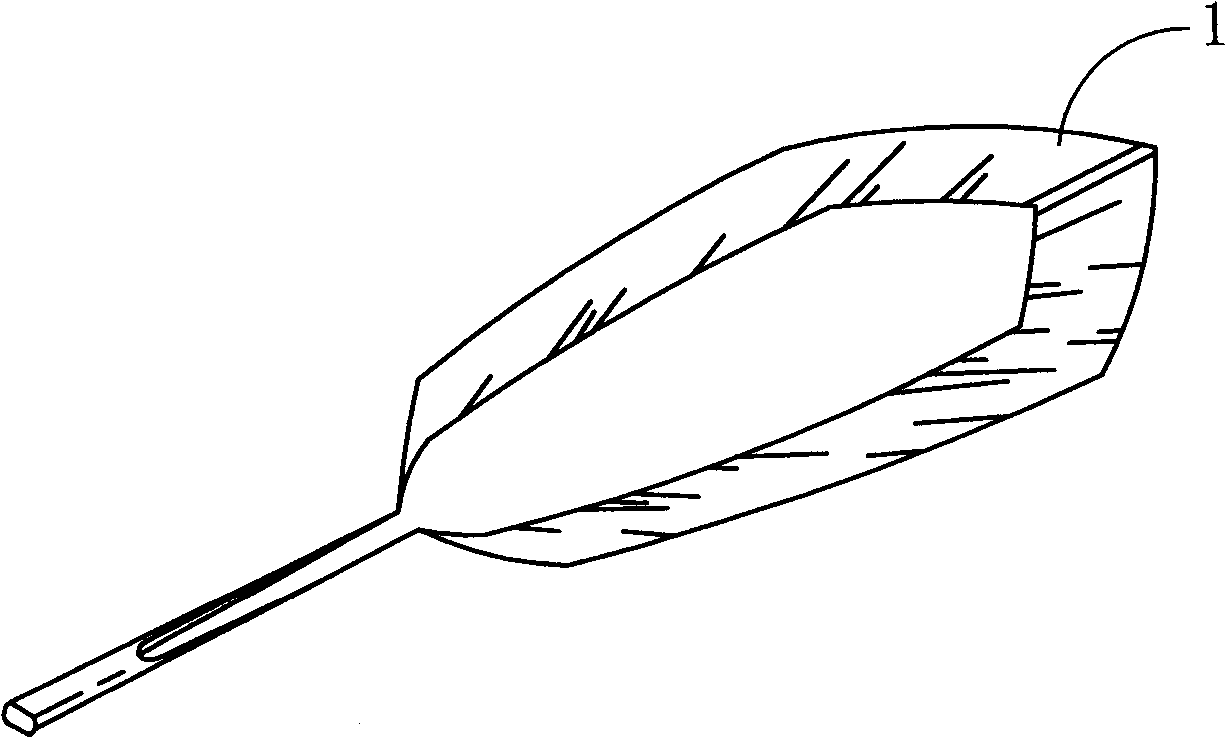

Method for manufacturing badminton pinnae

A production method and badminton technology, applied in the direction of sports accessories, etc., can solve the problems of low work efficiency, insufficient adhesive strength, artificial wings falling off, etc., and achieve the effect of improving production efficiency, improving environmental protection performance, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

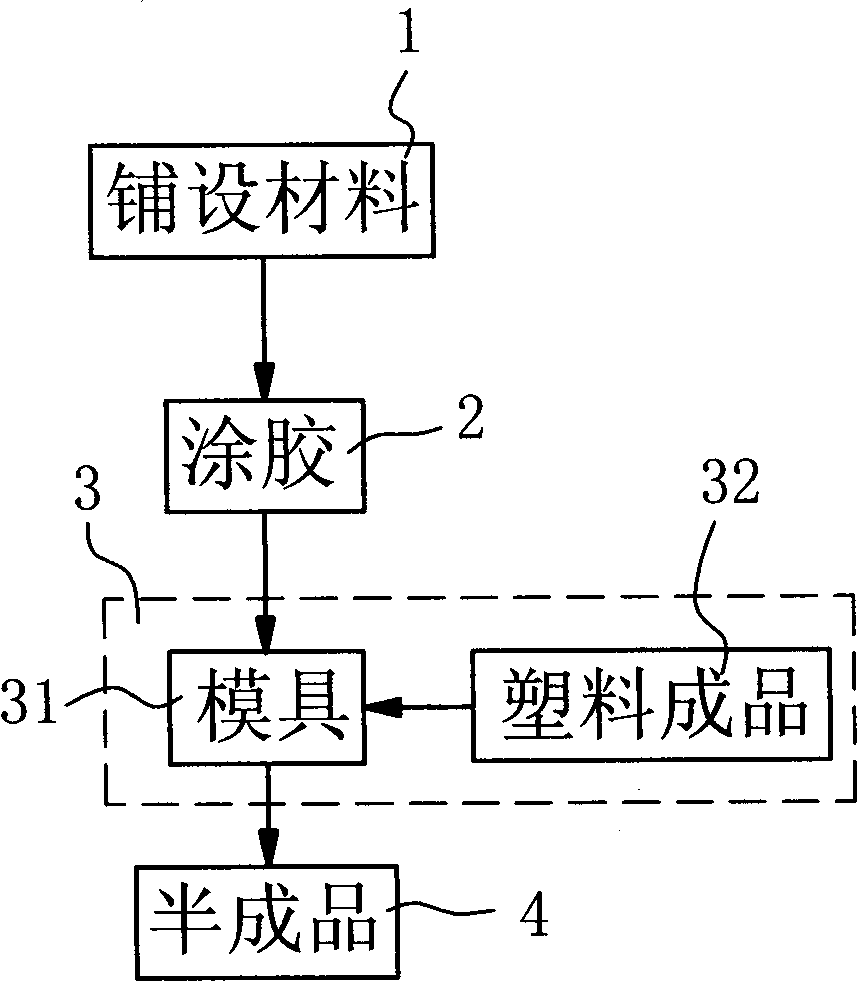

[0040] The following is based on Figure 2 to Figure 13 Shown, the embodiment of the present invention is stated:

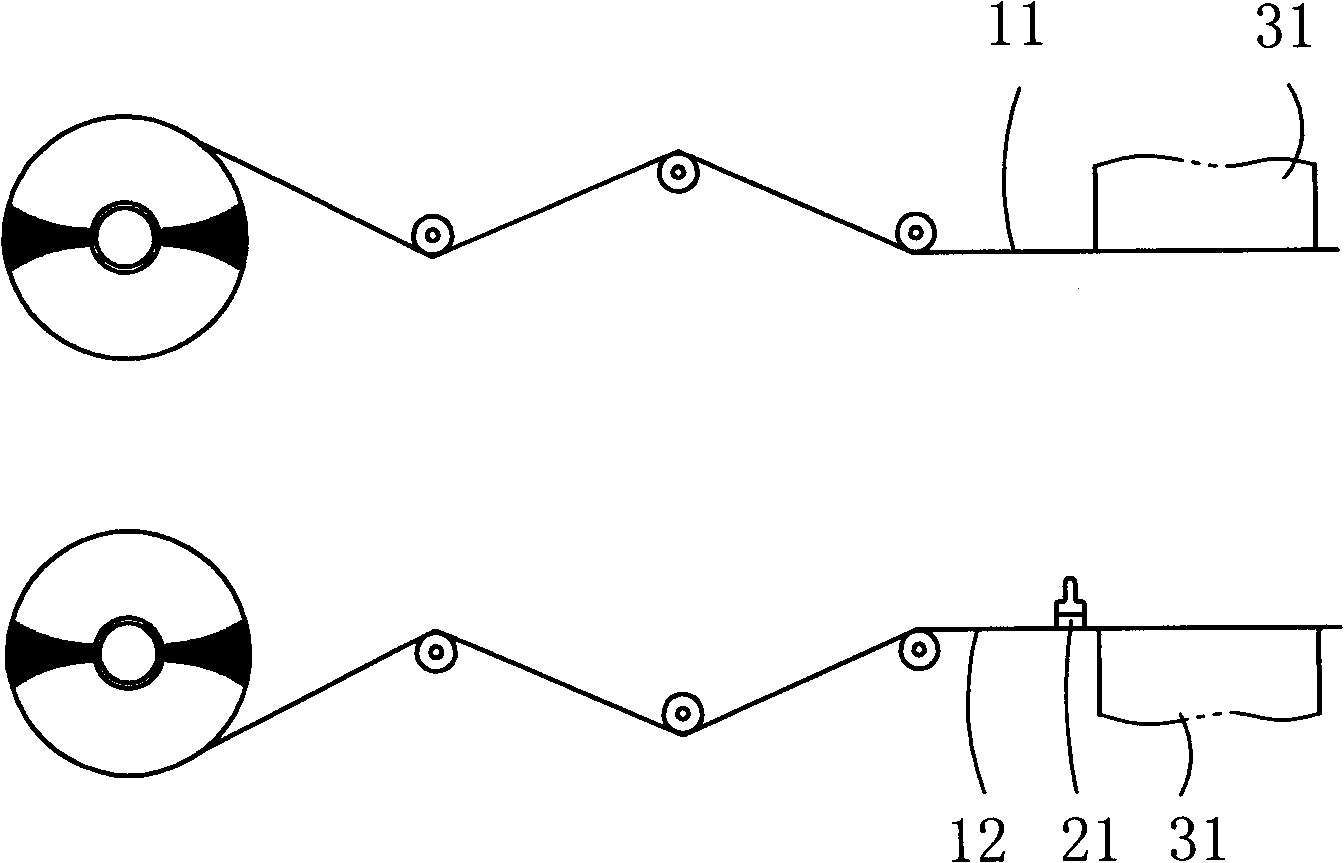

[0041] The present invention relates to a kind of badminton pinna manufacturing method, such as figure 2 in, combine Figure 3 to Figure 13 As shown, it at least includes paving materials 1, glue coating 2, mold processing 3, and semi-finished products 4; among them:

[0042] Laying material 1: It is the action of dividing the material into relative upper ribs 11 and lower ribs 12 and pulling them out at the same time, and allowing the lower ribs 12 to apply glue 2;

[0043] Gluing 2: use the brushing device 21 to apply glue to the side opposite to the upper bone 11 before the lower bone 12 enters the mold processing 3, so that the upper bone 11 and the lower bone 12 can be bonded to each other;

[0044] Mold processing 3: pull the upper bone 11 and the lower bone 12 that has been glued 2 to the middle of the two opposite molds 31, and set a plastic product 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com