Automatic grinding processing production line of magnetic tile

A production line and grinding technology, which is applied to metal processing equipment, machine tools suitable for grinding workpiece planes, machine tools suitable for grinding workpiece edges, etc., can solve problems such as chaotic production line layout, large footprint, and safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

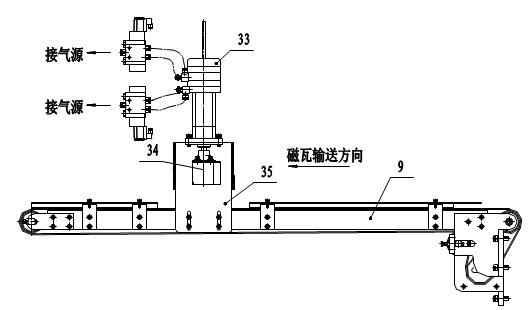

[0029] Embodiment 3 of the magnetic tile steering mechanism used in the above-mentioned production line, the magnetic tile steering mechanism uses a uniform circular motion mechanism to complete the magnetic tile steering. Such as Figure 6As shown, the motor (not shown in the figure) directly drives the runner 21 to perform uniform circular motion. Since the claw assembly 18 is connected to the runner 21, the claw also performs uniform circular motion and will enter the steering position from the "A" position. The magnetic tile of the mechanism is moved along the guide rail 20 and turned to reach the "B" position to realize the magnetic tile steering. In order to prevent the magnetic tile from being driven by the claw to rotate after the steering, an inclined block can be set at the exit "B" position, and its inclined surface is connected with the guide rail 20 and the conveyor belt of the next process, and the magnetic tile reaches the "B" position Promptly slide down to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com