Method and adjustable bracket for controlling edge effect of aluminum plate base for printing plates

An edge effect, aluminum plate base technology, applied in anodizing and other directions, can solve the problems of inability to adjust the height of the backing plate, affect production efficiency, and labor-intensive, and achieve the effect of convenient implementation, simple structure, and reduced edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

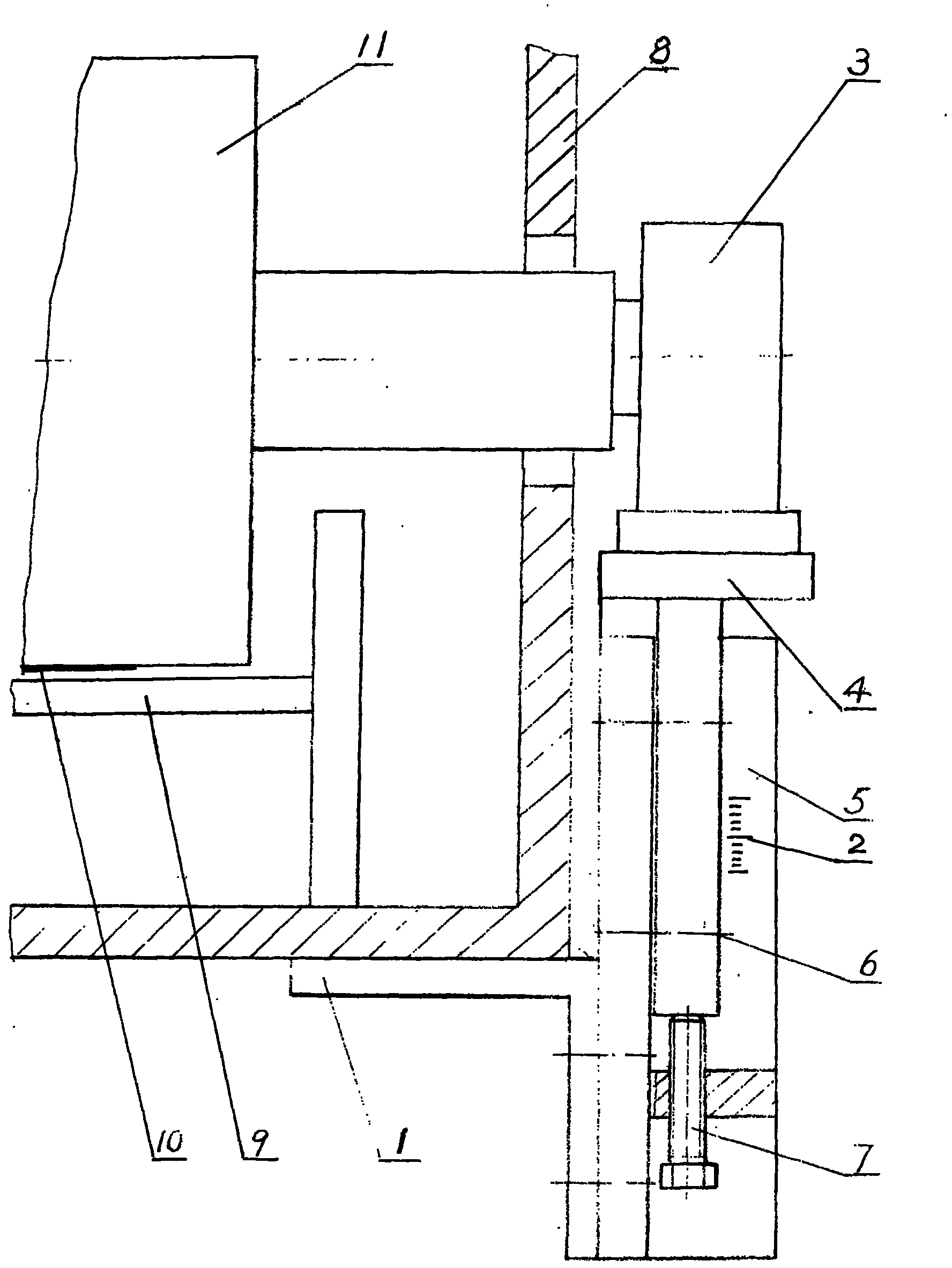

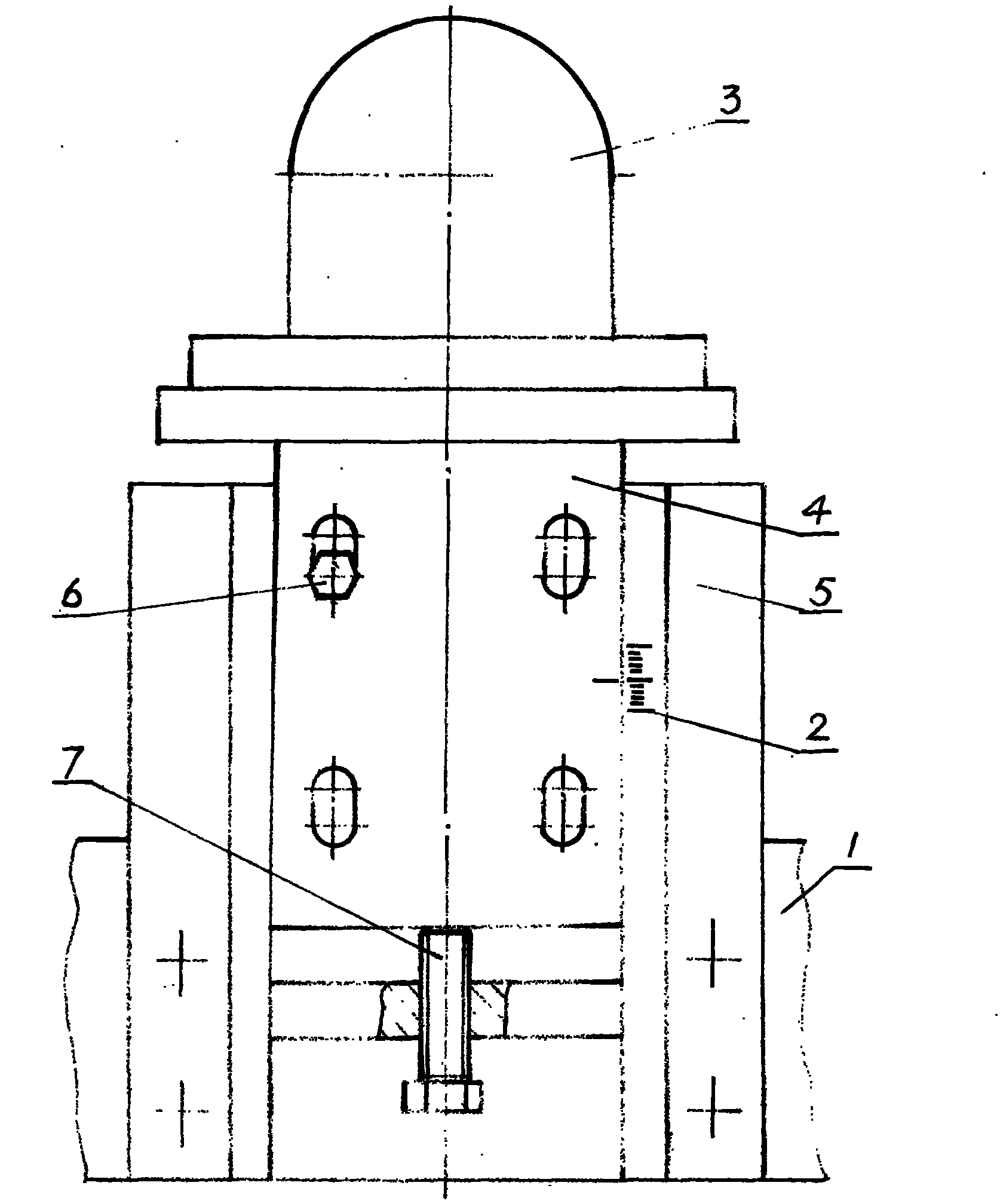

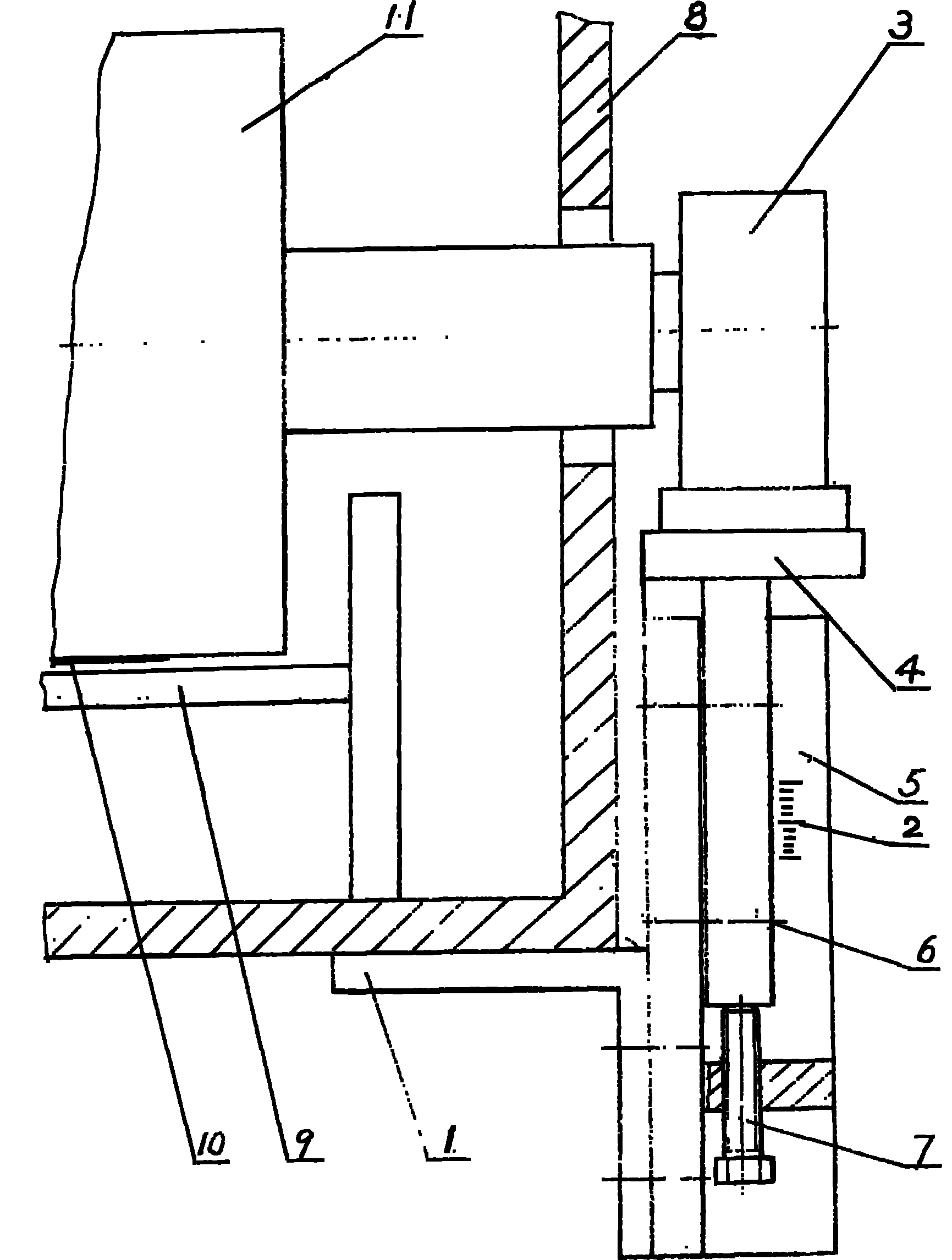

[0012] Referring to the accompanying drawings, the present invention will be further described.

[0013] 1. Install the bearing seat 3 of the lower rubber roller 11 in the electrolysis (or oxidation) tank 8 on the frame 1 through a symmetrically arranged adjustable bracket. The adjustable bracket is mainly connected by the sliding seat 4, the fixed seat 5 and the two The scale 2 on the outer surface of the sliding guide rail is formed by adding the adjusting bolt 7, wherein the sliding seat 4 is integrated with the bearing seat 3, and the fixed seat 5 is installed on the frame 1.

[0014] 2. When the lower rubber roller is initially installed, adjust the adjustable bracket and change the upper and lower positions of the lower rubber roller so that there is a gap between the aluminum plate base 10 that is close to the lower edge of the lower rubber roller and the backing plate 9 located below the lower rubber roller. 0~2mm distance, parallelism ≤0.3mm, and make the scale scale ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap