Novel built-in cable-truss anchoring structure and construction method thereof

A built-in, new type of technology, applied in bridge form, bridge parts, erection/assembly of bridges, etc., can solve problems such as inconvenient construction, damage to the integrity of the bridge deck, and small space for the arrangement of anchor boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

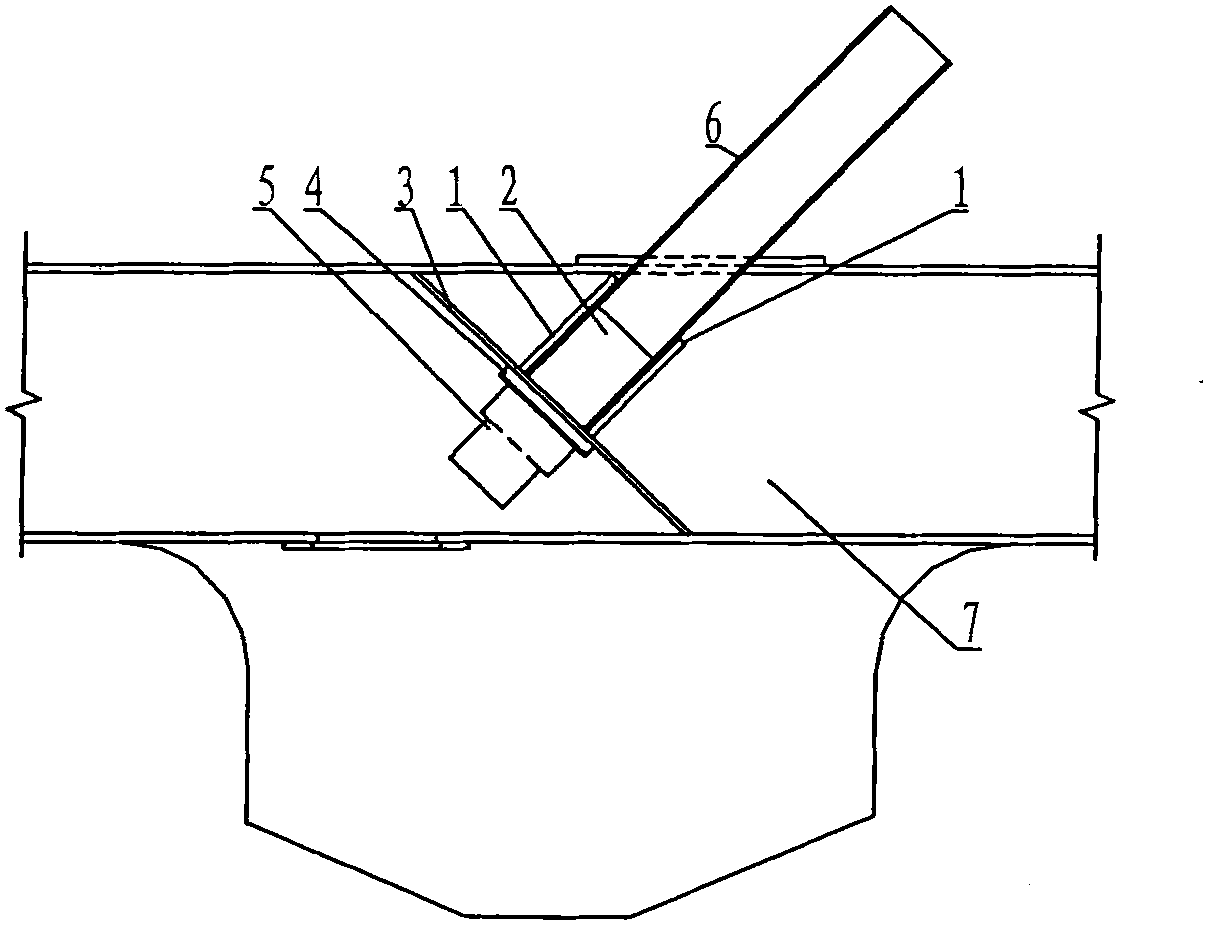

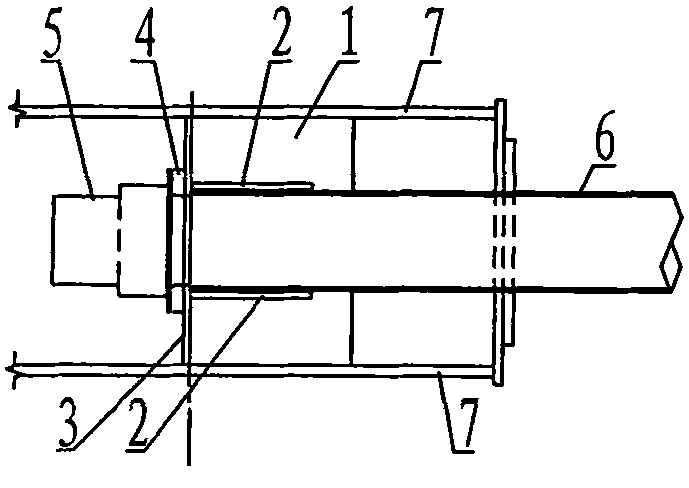

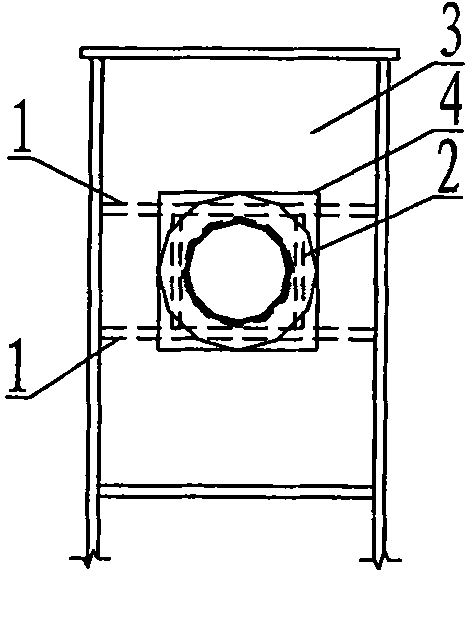

[0018] refer to figure 1 , 2 , 3, 4, 5, the anchor box horizontal bearing plate 1 of the new built-in cable truss anchorage structure of the present invention is welded into an anchor box with the overall gusset plate 7 in the width direction and the vertical bearing plate 2 of the anchor box in the vertical direction, satisfying Stress requirements for panel structures. The lower ends of the vertical load-bearing plate 2 and the horizontal load-bearing plate 1 of the anchor box are welded to the main truss node diaphragm 3, and the main truss node diaphragm 3 is arranged along the vertical direction of the cable axis and placed in the center of the main truss node. 6 is arranged in the anchor box along the cable axis, the lower end is welded together with the main truss node diaphragm, and the anchor backing plate 4 is welded with the lower side of the main truss node diaphragm 3 . The anchor backing plate is divided into two pieces, and the contact surface between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com