Automatic classification and detection equipment for RVM of goblet

A technology for automatic sorting and testing equipment, which is applied to household appliances, garbage collection, garbage cleaning, etc. It can solve the problem of limited storage of bottle cans, and achieve the effect of avoiding mildew and deterioration, improving stability and small rebound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

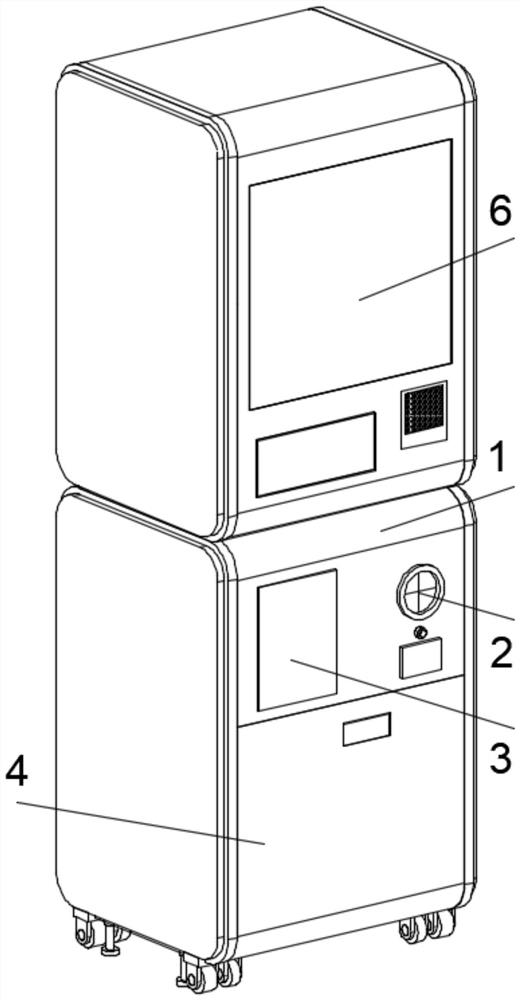

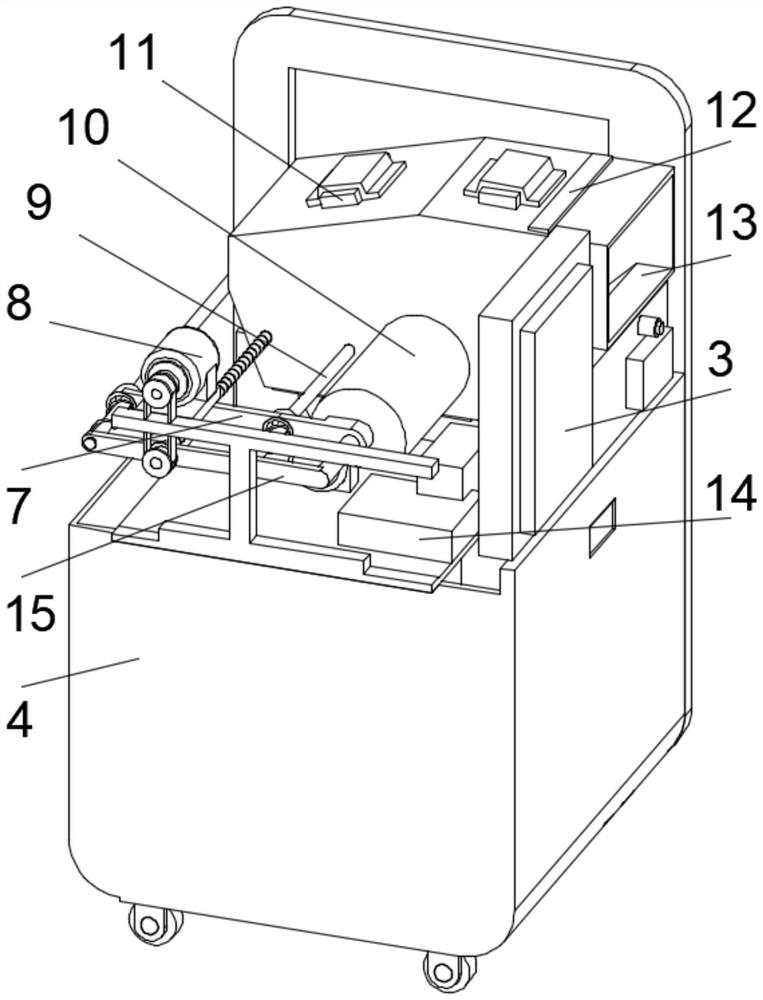

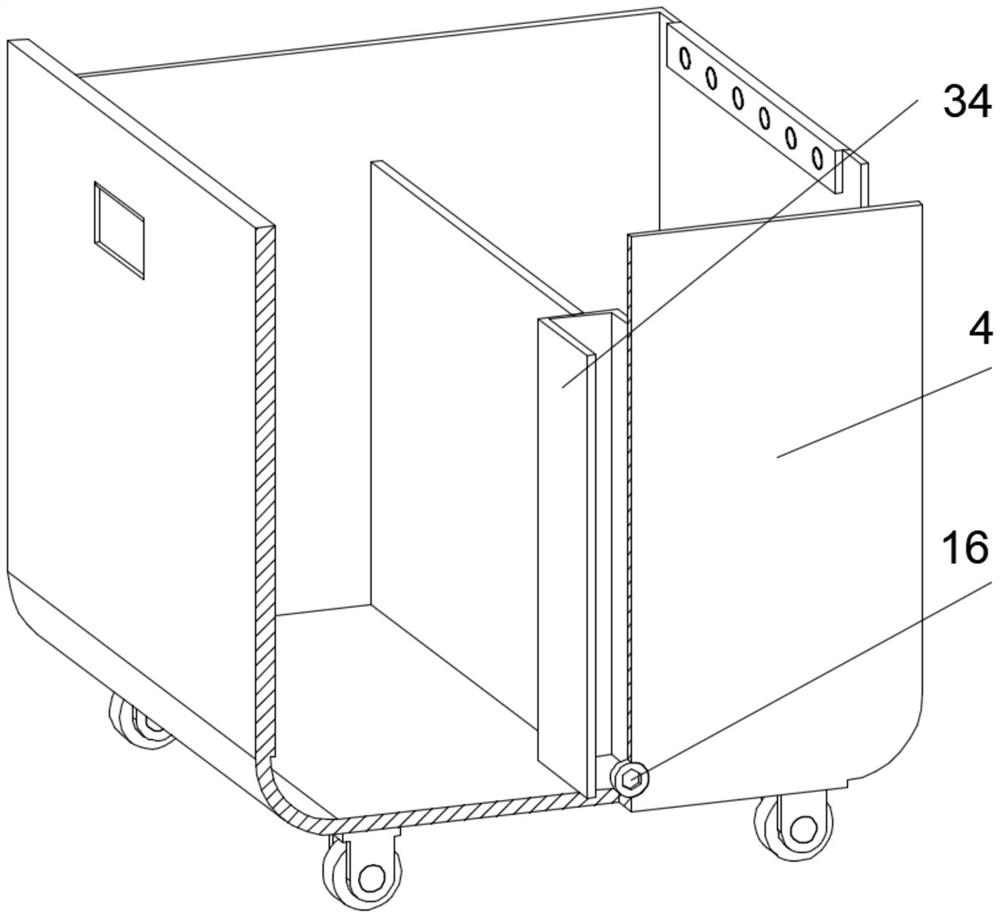

[0041] like Figure 1-8 As shown, a bottle RVM automatic classification and detection equipment includes a casing 1, a storage port 2 is installed through the right part of the front side of the casing 1, a pilot box 13 is installed on the rear side of the casing 1 at the rear side of the storage port 2, and the left side of the pilot box 13 is opened. There is a telescopic hole, the pilot box 13 is located at the position of the telescopic hole to install the limit sleeve 10, the middle of the limit sleeve 10 is installed with an extrusion rod 23, and the left part of the inner side of the housing 1 is installed to drive the limit sleeve 10 and the extrusion rod 23 to move laterally. A storage box 4 is installed in the lower part of the inner side of the casing 1, a flip frame is installed in the middle of the bottom end of the pilot box 13, and a collection shell 30 is installed in the right part of the bottom end of the pilot box 13.

[0042]A vending machine 6 is installed...

Embodiment 2

[0052] like Figure 1-8 As shown, a bottle RVM automatic classification and detection equipment, including a bottle of bottle RVM automatic classification detection equipment, including a shell 1, the front right part of the shell 1 is installed through a storage port 2, and the shell 1 is installed at the rear side of the storage port 2 There is a pilot box 13, a telescopic hole is opened on the left side of the pilot box 13, a limit sleeve 10 is installed in the pilot box 13 at the position of the telescopic hole, an extrusion rod 23 is installed through the middle of the limit sleeve 10, and the right end of the extrusion rod 23 is provided with a tapered Needle 24, a drive assembly that drives the limit sleeve 10 and the extrusion rod 23 to move left and right is installed on the left side of the inner side of the housing 1, a storage box 4 is installed on the lower part of the inner side of the housing 1, and a flip frame is installed in the middle of the bottom end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com