Foam material for shoes as well as preparation method and application thereof

A technology for foam materials and shoes is applied in the field of foam materials for shoes, and can solve the problems of reduced material properties, mechanical properties such as the resistance to compression deformation of microcellular foam soles, etc. to be improved, etc., and achieves high resilience and good wearability. and running experience, the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

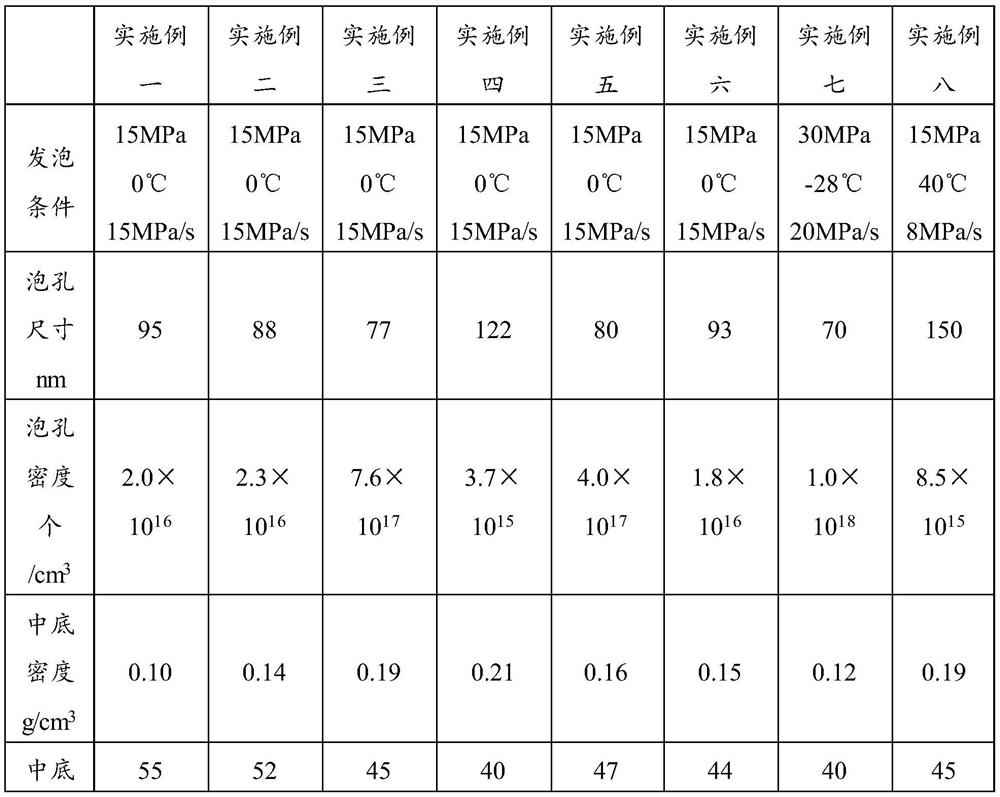

Examples

preparation example Construction

[0048] Embodiments of the present invention provide a method for preparing a foam material for shoes as described above, comprising the following steps:

[0049] Mixing and injection molding each component in the nylon elastomer composite material to obtain a nylon elastomer composite material;

[0050] The nylon elastomer composite material is impregnated to equilibrium in a high-pressure fluid atmosphere, then quickly released, dried and aged to obtain a foam material for shoes.

[0051] In the embodiment of the present invention, each component in the nylon elastomer composite material is weighed in parts by weight; the weighed nylon elastomer composite material is mixed and injected. Specifically, the present invention preferably adds the nylon elastomer composite material into the barrel of a twin-screw extruder after drying, stirring and mixing, melts and kneads, and injects it into a mold with a midsole shape to obtain a midsole-shaped composite material. Bottom-shaped...

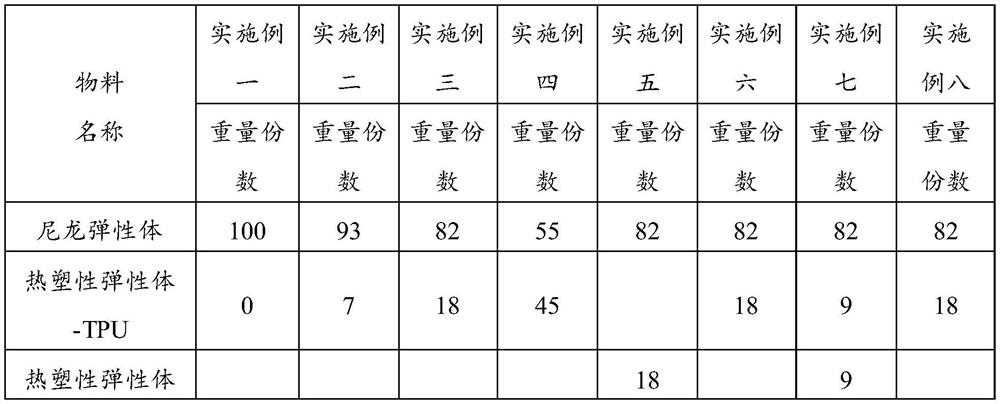

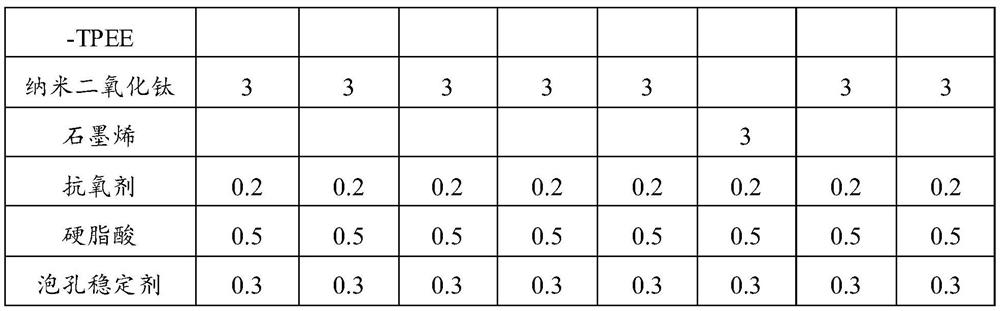

Embodiment 1

[0059] In an embodiment of the present invention, the nylon elastomer composite material includes the following components in parts by mass:

[0060] Nylon elastomer: 100 parts;

[0061] Antioxidant: 0.2 parts;

[0062] Nano nucleating agent: 3 parts;

[0063] Stearic acid: 0.5 parts;

[0064] Cell stabilizer: 0.3 part;

[0065] Wherein, the antioxidant is AT-10; the nano-nucleating agent is nano-titanium dioxide; the cell stabilizer is polyisobutyl methacrylate.

[0066] After drying, stirring and mixing the weighed above components, put them into the barrel of the twin-screw extruder for melting and kneading, and inject them into the midsole-shaped mold to obtain the midsole-shaped nylon elastomer composite sheet materials; among them, the barrel temperature is 240°C, the mold temperature is 40°C, the injection pressure is 780bar, and the holding pressure is 350bar.

[0067] The obtained nylon-elastomer composite sheet is impregnated to solubility balance under a carbon...

Embodiment 2

[0069] In an embodiment of the present invention, the nylon elastomer composite material includes the following components in parts by mass:

[0070] Nylon elastomer: 93 parts;

[0071] Thermoplastic polyurethane: 7 parts;

[0072] Antioxidant: 0.2 parts;

[0073] Nano nucleating agent: 3 parts;

[0074] Stearic acid: 0.5 parts;

[0075] Cell stabilizer: 0.3 part;

[0076] Among them, the antioxidant is AT-10; the nano-nucleating agent is nano-titanium dioxide; the cell stabilizer is polyisobutyl methacrylate.

[0077] After drying, stirring and mixing the weighed above components, put them into the barrel of the twin-screw extruder for melting and kneading, and inject them into the midsole-shaped mold to obtain the midsole-shaped nylon elastomer composite sheet material; among them, the barrel temperature is 240°C, the mold temperature is 40°C, the injection pressure is 780bar, and the holding pressure is 350bar.

[0078] The obtained nylon-elastomer composite sheet is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com