Preparing method of once butyronitrile glazing and twice butyronitrile foaming gloves

A technology of gloves and nitrile, which is applied in the direction of coating, etc., can solve the problems of easy penetration into gloves, slow rebound, and easy falling off of rubber sheets, and achieve the effects of simple production process, reduced vibration, and protection of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of nitrile butyronitrile foamed glove with smooth surface twice adopts the following steps:

[0039] (1), material preparation: pre-vulcanized carboxylated nitrile latex, thickener, potassium oleate, nonylphenoxy polyethanol, KOH, etc.;

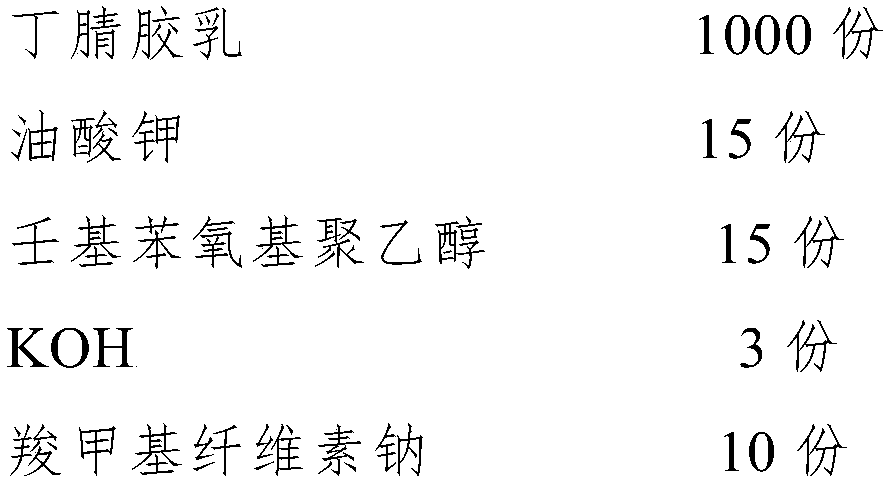

[0040] (2), glue adjustment: the first impregnated glue, the quality ratio of the glue is as follows:

[0041] Nitrile latex 1000 parts

[0042] Sodium polyacrylate 12 parts.

[0043] Styrofoam, the mass ratio of the rubber material is as follows, after the raw materials are mixed, stir to make the foaming volume 1.7;

[0044]

[0045] (3) Preheating: put the glove embryo on the hand mold, and preheat the hand mold, the preheating temperature is 50°C, soak the coagulant once (methanol: calcium nitrate mass ratio = 100:2), after the coagulant treatment , soaked in styrofoam;

[0046] (4), immerse the coagulant twice: immerse the gloves soaked in styrofoam in the coagulant (water:calcium chloride mass ratio=...

Embodiment 2

[0051] The preparation method of nitrile butyronitrile foamed glove with smooth surface twice adopts the following steps:

[0052] (1), material preparation: pre-vulcanized carboxylated nitrile latex, thickener, potassium ricinoleate, nonylphenoxy polyethanol, KOH, etc.;

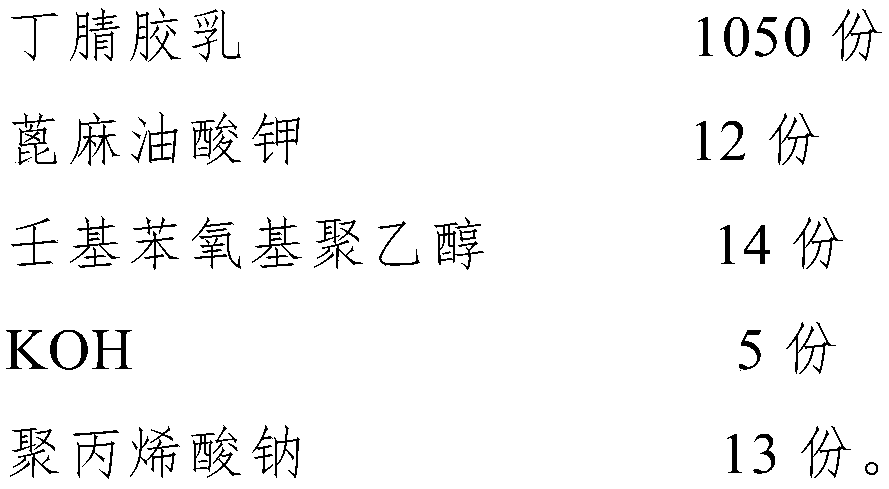

[0053] (2), glue adjustment: the first impregnated glue, the quality ratio of the glue is as follows:

[0054] Nitrile latex 950 parts

[0055] Casein 10 parts.

[0056] Styrofoam, the mass ratio of the rubber material is as follows, after the raw materials are mixed, stir to make the foaming volume 1.8;

[0057]

[0058] (3) Preheating: put the glove embryo on the hand mold, and preheat the hand mold. The preheating temperature is 50°C, soak the coagulant once (ethanol: calcium chloride mass ratio = 100:3), and treat with the coagulant After that, soak the styrofoam;

[0059] (4), soak the coagulant twice: immerse the gloves soaked in styrofoam in the coagulant (methanol:calcium nitrate mass ratio=10...

Embodiment 3

[0064] The preparation method of nitrile butyronitrile foamed glove with smooth surface twice adopts the following steps:

[0065] (1), material preparation: pre-vulcanized carboxylated nitrile latex, thickener, potassium oleate, alkyl naphthalene sulfonate, KOH, etc.;

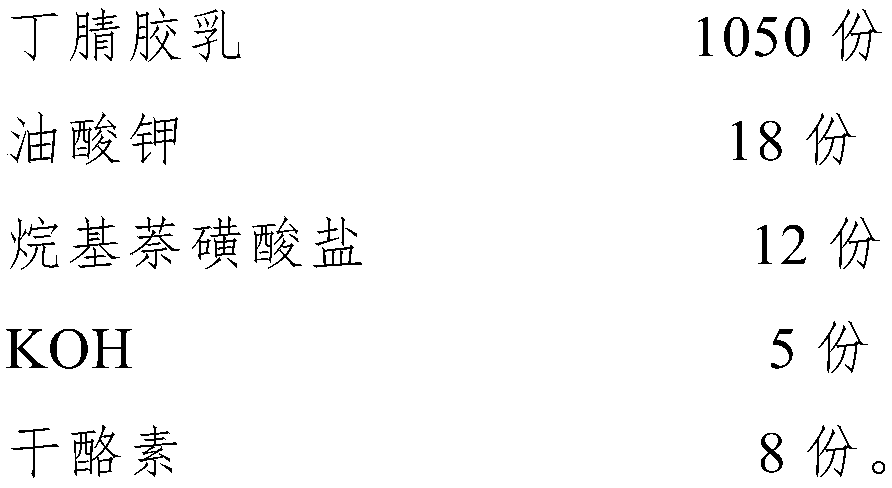

[0066] (2), glue adjustment: the first impregnated glue, the quality ratio of the glue is as follows:

[0067] Nitrile latex 1100 parts

[0068] Sodium polyacrylate 17 parts.

[0069] Styrofoam, the mass ratio of the rubber material is as follows, after the raw materials are mixed, stir to make the foaming volume 1.6;

[0070]

[0071] (3) Preheating: put the glove embryo on the hand mold, and preheat the hand mold, the preheating temperature is 55°C, soak the coagulant once (methanol: calcium chloride mass ratio = 100:5), and treat with the coagulant After that, soak the styrofoam;

[0072] (4), soak the coagulant twice: immerse the gloves soaked in styrofoam in the coagulant (ethanol: calcium nitrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com