A heat-insulating and wear-resistant lining board for coke-quenching car doors

A wear-resistant liner and door technology, which is applied in the field of coke quenching vehicles, can solve the problems of overhaul or replacement, damage, rupture and damage of coke quenching vehicles, and achieve the effect of saving resources and reducing overhaul and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

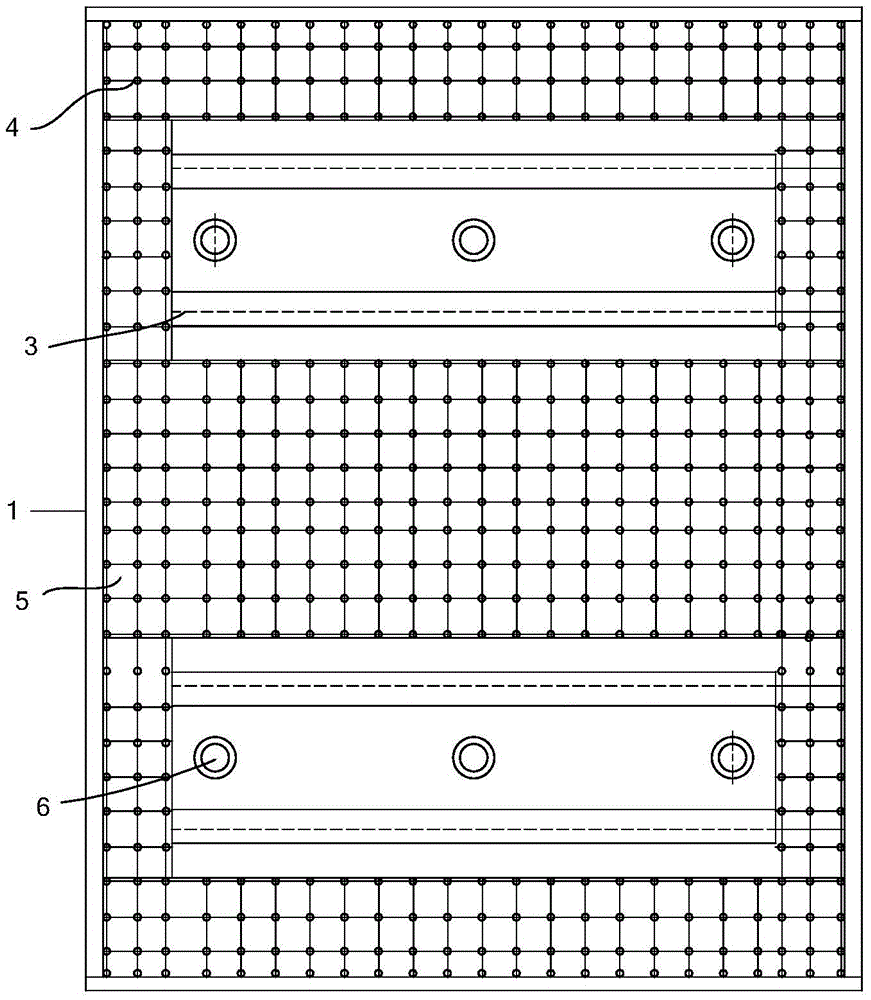

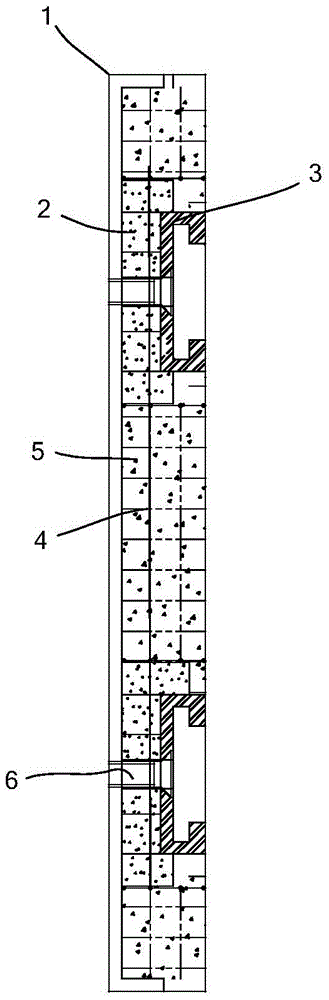

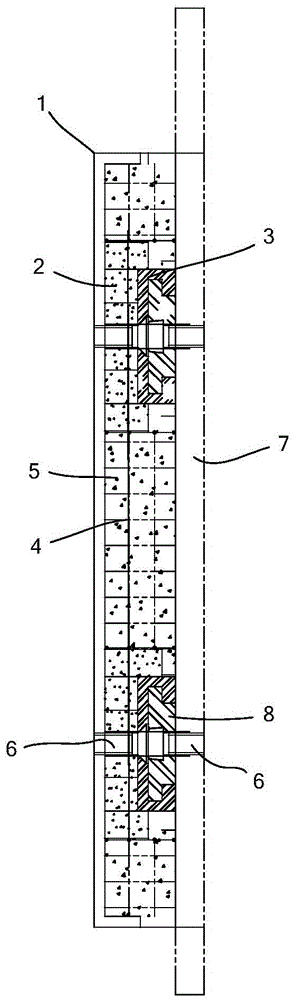

[0022] like figure 1 and figure 2 As shown, the heat-insulating and wear-resistant liner for coke-quenching vehicle doors of the present invention includes a housing 1 , a fixing seat 2 , a connecting portion 3 , a support frame 4 and a heat-insulating layer 5 . Wherein, the housing 1 is a rectangular outer cover with a groove inside, which can be formed by bending a piece of steel plate in actual production. In order to make the housing 1 have wear resistance, the material of the housing 1 in this embodiment is 2Cr23Ni13 or other Heat-resistant steel with si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com