System for automatically adjusting temperature of smoke at outlet of waste heat boiler

A technology of flue gas temperature and waste heat boiler, which is applied in steam superheating, lighting and heating equipment, steam generation, etc., and can solve problems such as insufficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

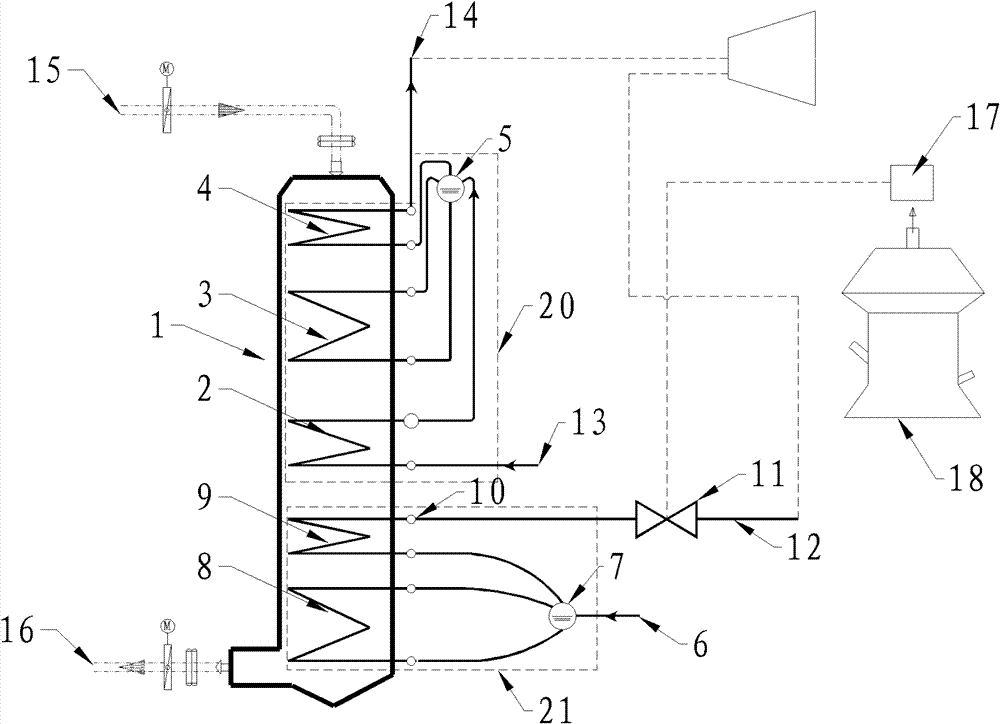

[0022] The SP waste heat boiler at the kiln tail of a new dry-process cement production line is modified by applying the present invention. The flue gas from the outlet of the SP waste heat boiler at the kiln tail is sent to the raw meal mill 18 of the raw meal system, and the steam is sent to the steam turbine 19 for power generation.

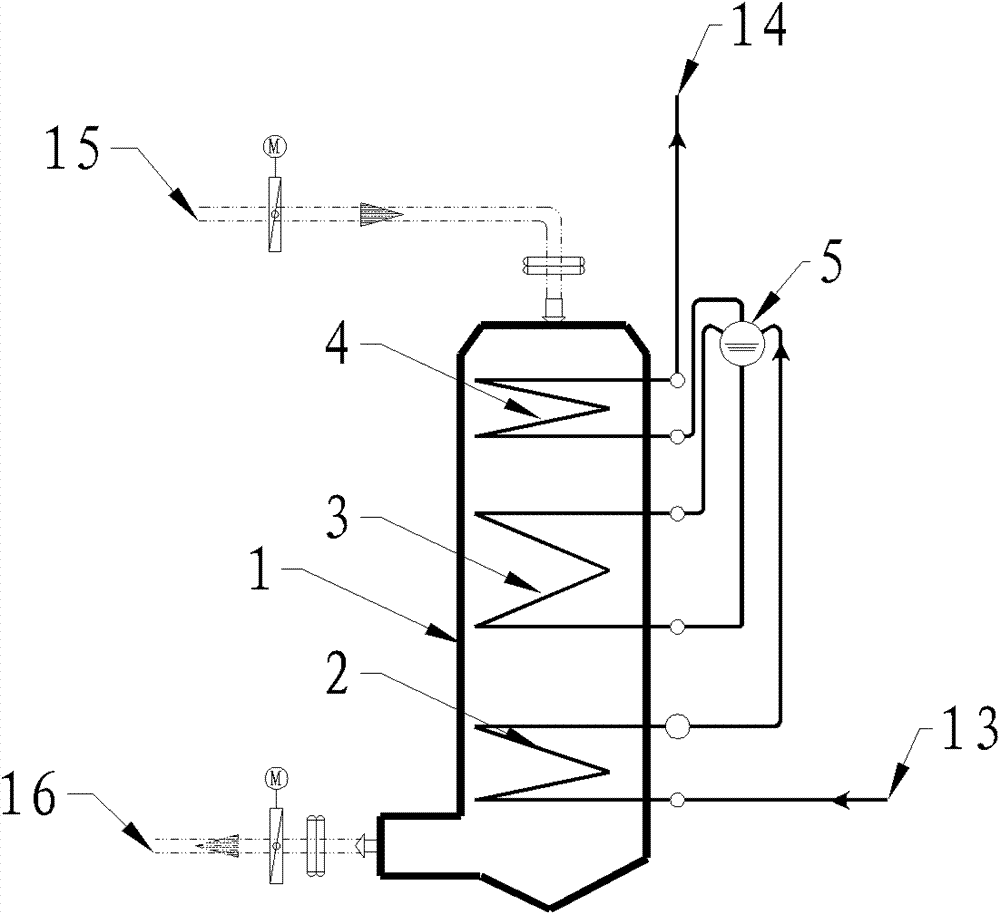

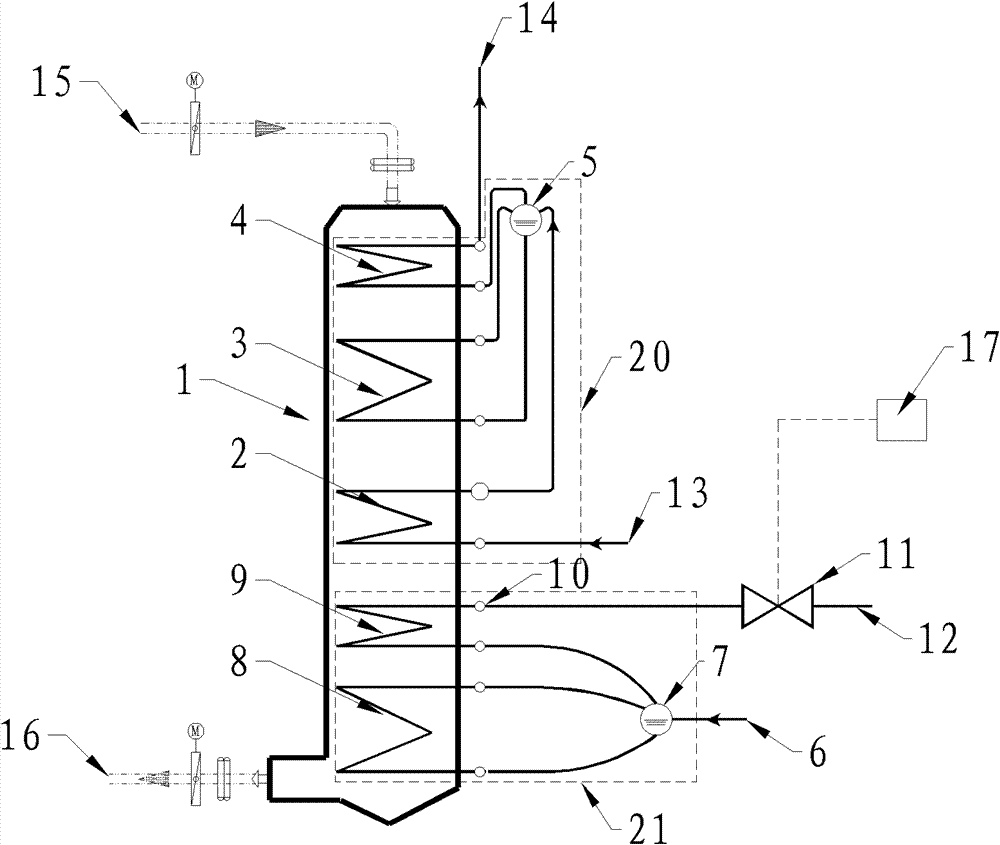

[0023] Such as image 3 As shown, in the waste heat boiler outlet flue gas temperature automatic adjustment system of the present invention, the boiler 1 is provided with a flue gas inlet 15, a flue gas outlet 16, and a superheating device 20 located between the flue gas inlet 15 and the flue gas outlet 16 and corresponding The water supply port 13 and the steam outlet 14, the superheating device 20 is composed of the evaporator 3, the superheater 4, the drum 5 and the economizer 2, the feed water enters the drum 5 through the water supply port 13 and the economizer 2, and evaporates The steam formed by the steam generator 3 and the superheate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com