Method for characterizing lamina structure of tobacco leaf

A blade structure and blade technology, which is applied in the field of characterization of tobacco leaf blade structure to achieve the effect of comprehensive structure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] (1) Sampling of samples: The present invention took samples of leaves of different origins and different grades after threshing, redrying and loosening and regaining moisture. There are 14 samples in total. As shown in Table 1, the sampling amount of each sample is 3.0 kg, in order to ensure the integrity of the blade structure, take the blade on the entire section of the conveyor belt as a test sample.

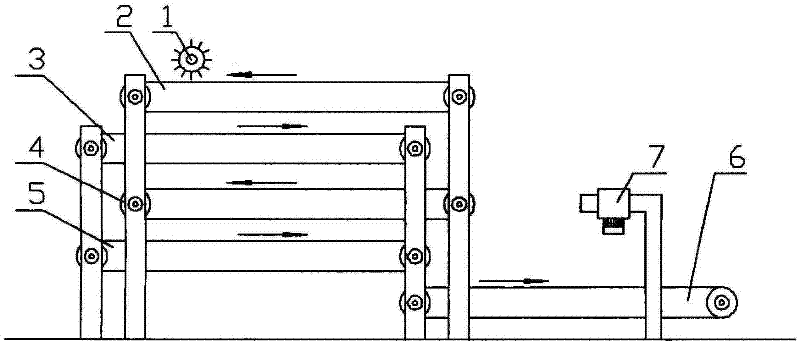

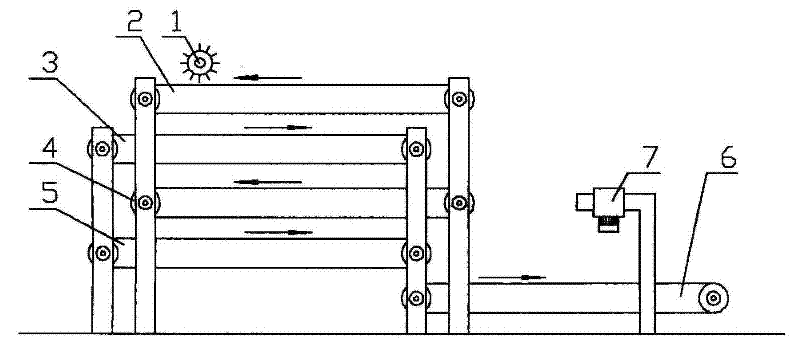

[0023] (2) Dispersed paving: In order to achieve the ideal dispersing effect and completely separate the blades, the present invention adopts a multi-stage dispersed paving method. The equipment used is shown in the figure: including a multi-stage belt conveying paving device and an image acquisition device , Place the taken leaf sample on the first-level belt 2, the flow of the leaf is controlled by the material limiting roller 1, the second, third, and fourth-level belts 3, 4, 5 speed up step by step, and the blades are gradually diluted and dispersed through the fourth-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com