Spiral tube micrometer element and micrometer device containing same

A helical tube and micrometric technology, which is used in measuring devices, test/calibration devices, engine components, etc., can solve problems such as non-conformity, limited resolution, and deviation of test values from true values, and achieve the effect of improving accuracy and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

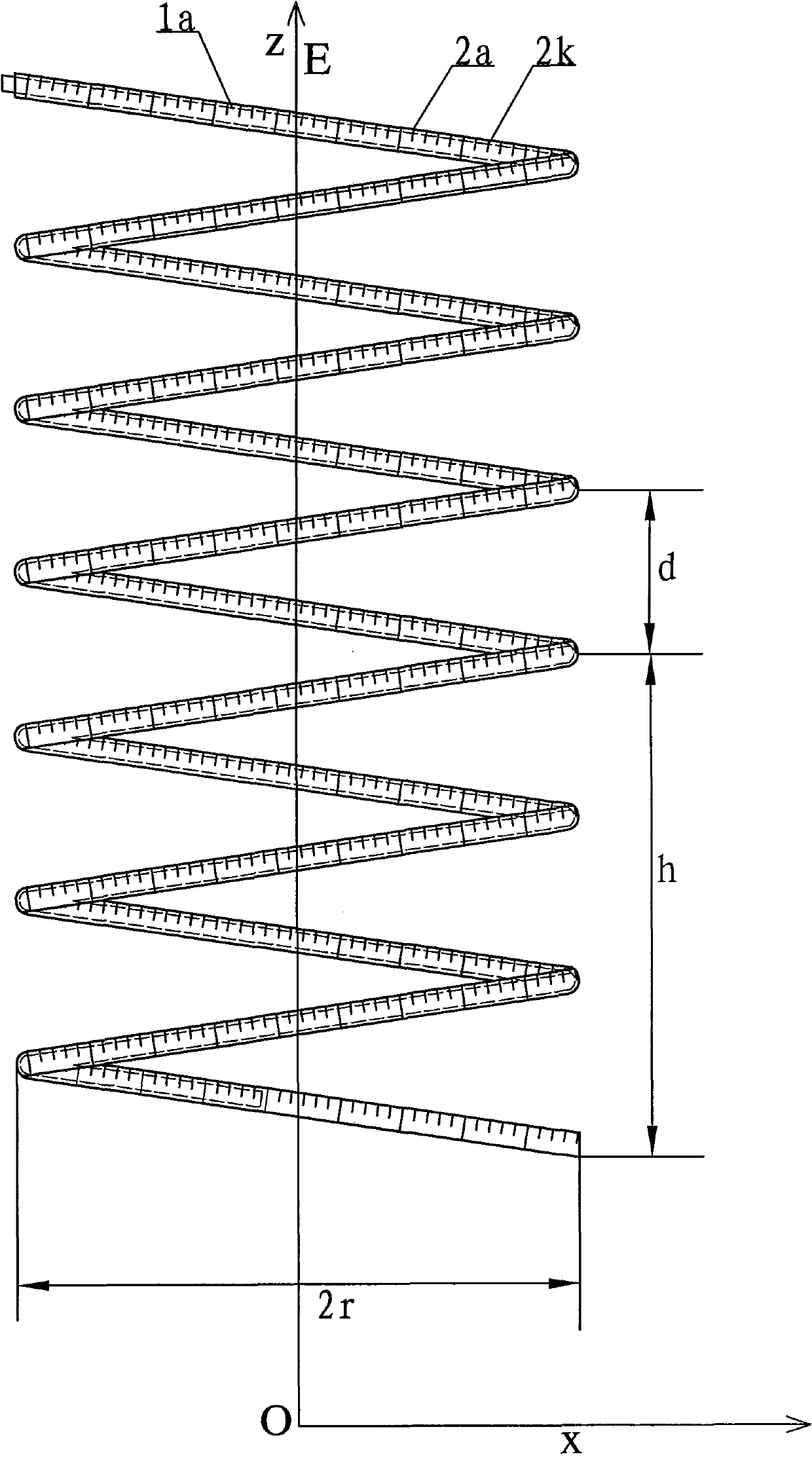

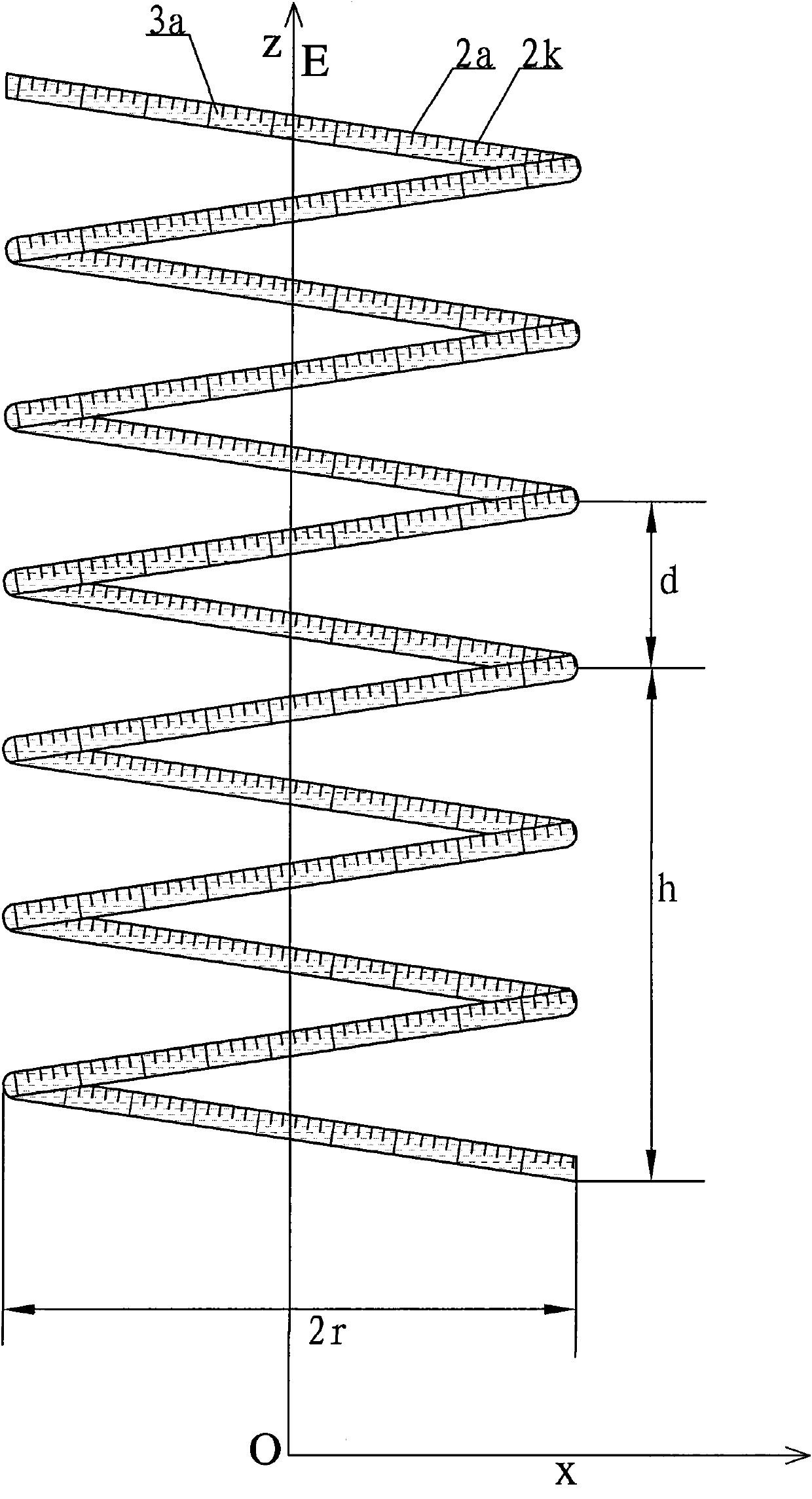

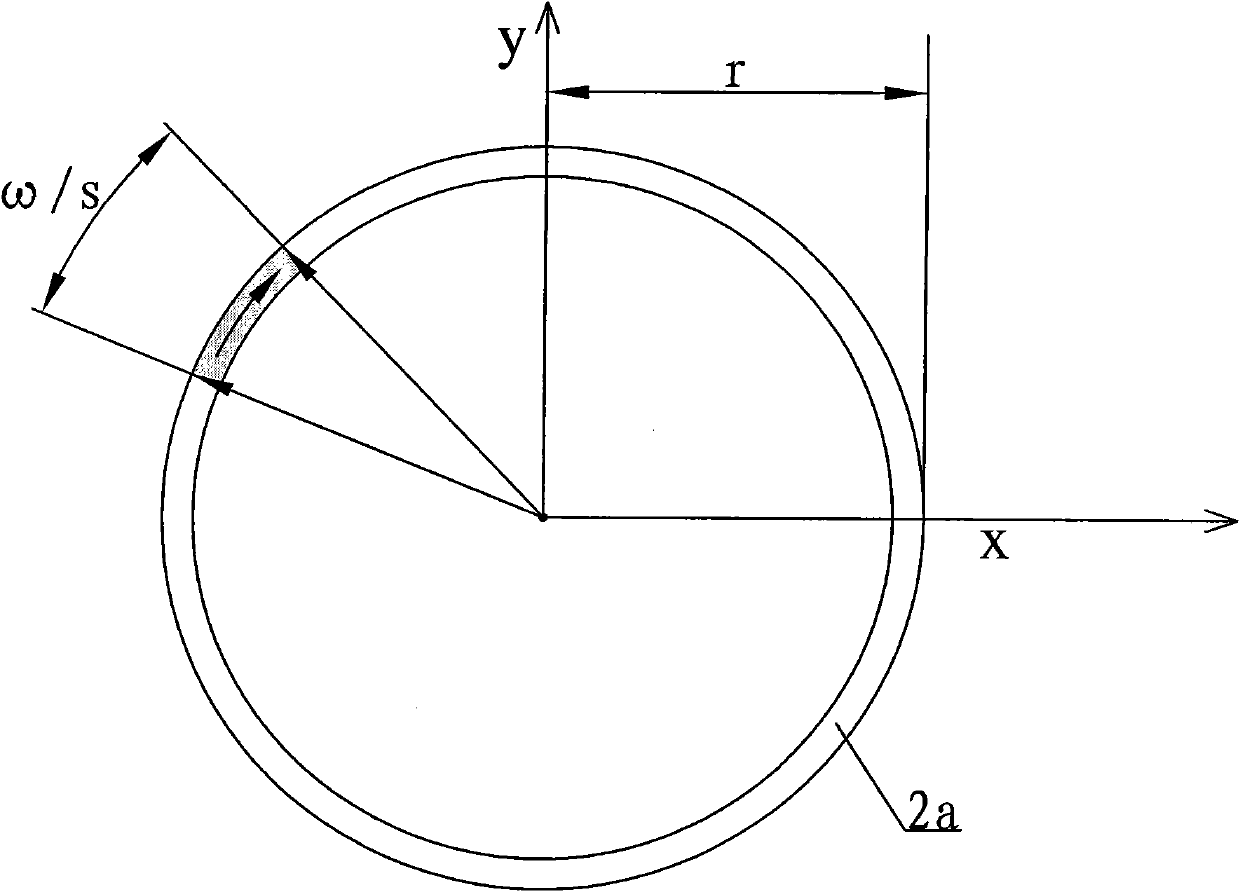

[0026] A spiral tube micrometer element, such as Figure 1 to Figure 4 As shown, it includes a pipe body 2a, the pipe body 2a is arranged along a cylindrical helical trajectory line with equal pitch d and equal helical radius r, and is fixed to form a helical helical tube, in which a liquid 3a or a receiving The wire rope 1a constrained by its lumen and adapted to its equal-pitch cylindrical helical trajectory, the outer peripheral wall of the wire rope 1a is in clearance fit with the inner peripheral wall of the helical tube, and the wire rope 1a is in dynamic fit with the inner tube wall of the helical tube. The silk rope 1a therein should meet the requirement that it will not be elongated substantially under tension.

[0027] Such as Figure 6 As shown, in order to avoid the capillary phenomenon caused by too small pipe diameter, the diameter of the outer pipe of the spiral pipe is Rgw≥5mm.

[0028] Such as figure 1 , image 3 , Figure 5 and Figure 6 As shown, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com