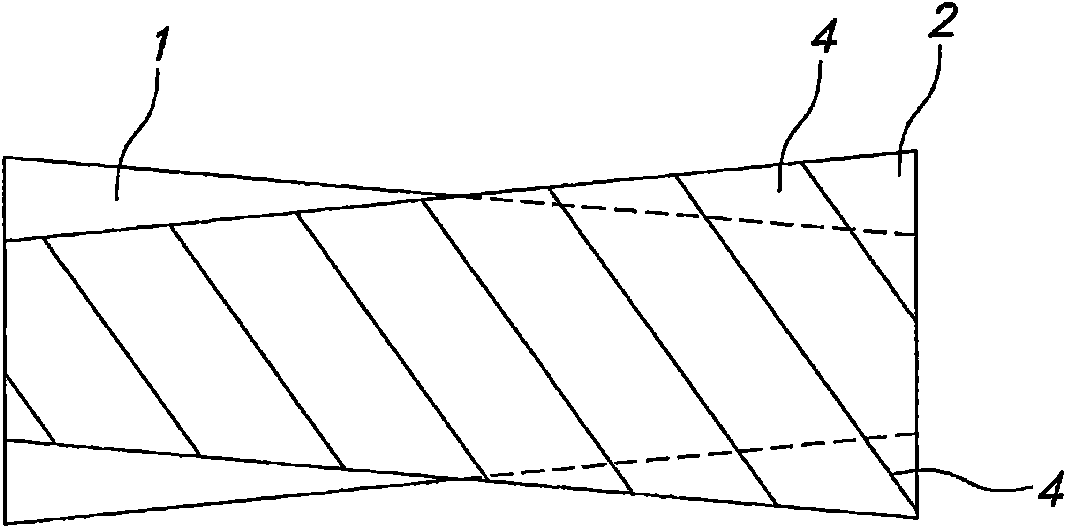

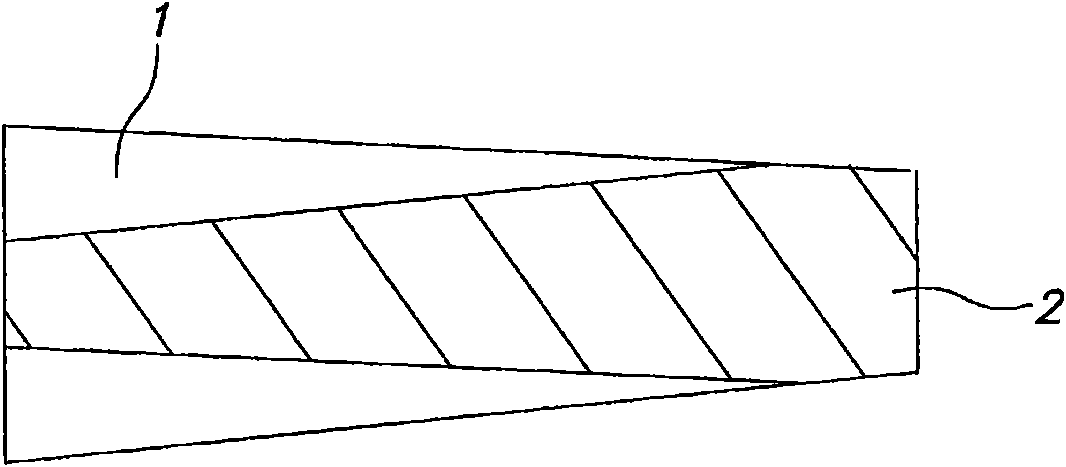

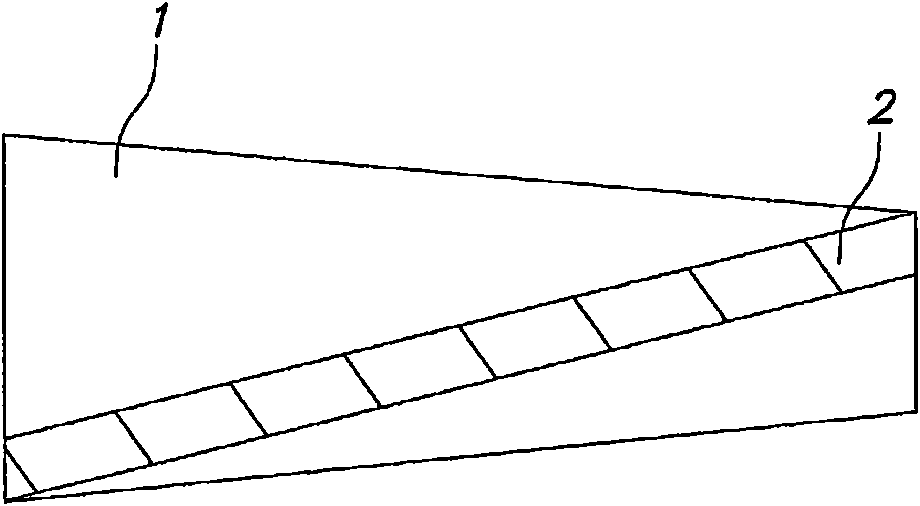

Garment with altered stress profile

A technology of stress distribution and clothing, which is applied to women's pajamas, uniforms, pajamas, etc., can solve the problems of fabric growth and achieve the effect of maximum comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0167] The preparation of the prepolymer was carried out in a glove box with a nitrogen atmosphere. In a 2000ml tank equipped with air-driven stirrer, heating mantle and thermocouple thermometer Add about 382.5 grams of 1800 diol and about 12.5 grams of DMPA. The mixture was heated to about 50°C with stirring, and about 105 grams of MI diisocyanate. The reaction mixture was then heated to about 90° C. with continuous stirring and then held at about 90° C. for about 120 minutes, after which time the reaction was complete, as the % NCO of the mixture dropped to a plateau matching that of the isocyanate-terminated Calculated for prepolymer (%NCO target of 1.914). The viscosity of the prepolymers was determined according to the general method of ASTM D1343-69 by using a Model DV-8 Falling Ball Viscometer (sold by Duratech Corp., Waynesboro, VA) operating at about 40°C. The total isocyanate moiety content (in terms of wt% of NCO groups) of blocked diol prepolymers was deter...

Embodiment 2

[0169] A solvent-free prepolymer prepared according to the procedure and composition described in Example 1 was used to make an aqueous polyurethaneurea dispersion.

[0170] Into a 2,000 ml stainless steel beaker were added about 700 grams of deionized water, about 15 grams of sodium dodecylbenzenesulfonate (SDBS), and about 10 grams of triethylamine (TEA). The mixture was then ice / water cooled to about 5°C and then mixed using a high shear laboratory mixer (Ross, Model 100LC) with a rotor / stator mixing head at about 5,000 rpm for about 30 seconds. A viscous prepolymer, prepared in the same manner as in Example 1 and contained in a metal tubular barrel, was added via flexible tubing to the mixing head in aqueous solution with the application of air pressure. bottom. The temperature of the prepolymer is maintained between about 50°C and about 70°C. The extruded prepolymer stream was dispersed and chain extended with water with continuous mixing at about 5,000 rpm. A total am...

Embodiment 3

[0172] The preparation procedure was the same as Example 2 except that no DEA was added to the dispersion after the prepolymer was mixed. Initially, the dispersion did not appear to be any different from Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com