Material-loading lifting mechanism of through-type abrator

A technology of shot blasting machine and lifting mechanism, which is applied in the direction of grinding/polishing equipment, etc., which can solve the problems of low production efficiency, high labor intensity, and inability to continuously load materials, and achieve the effect of simple structure and flexible and stable lifting action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

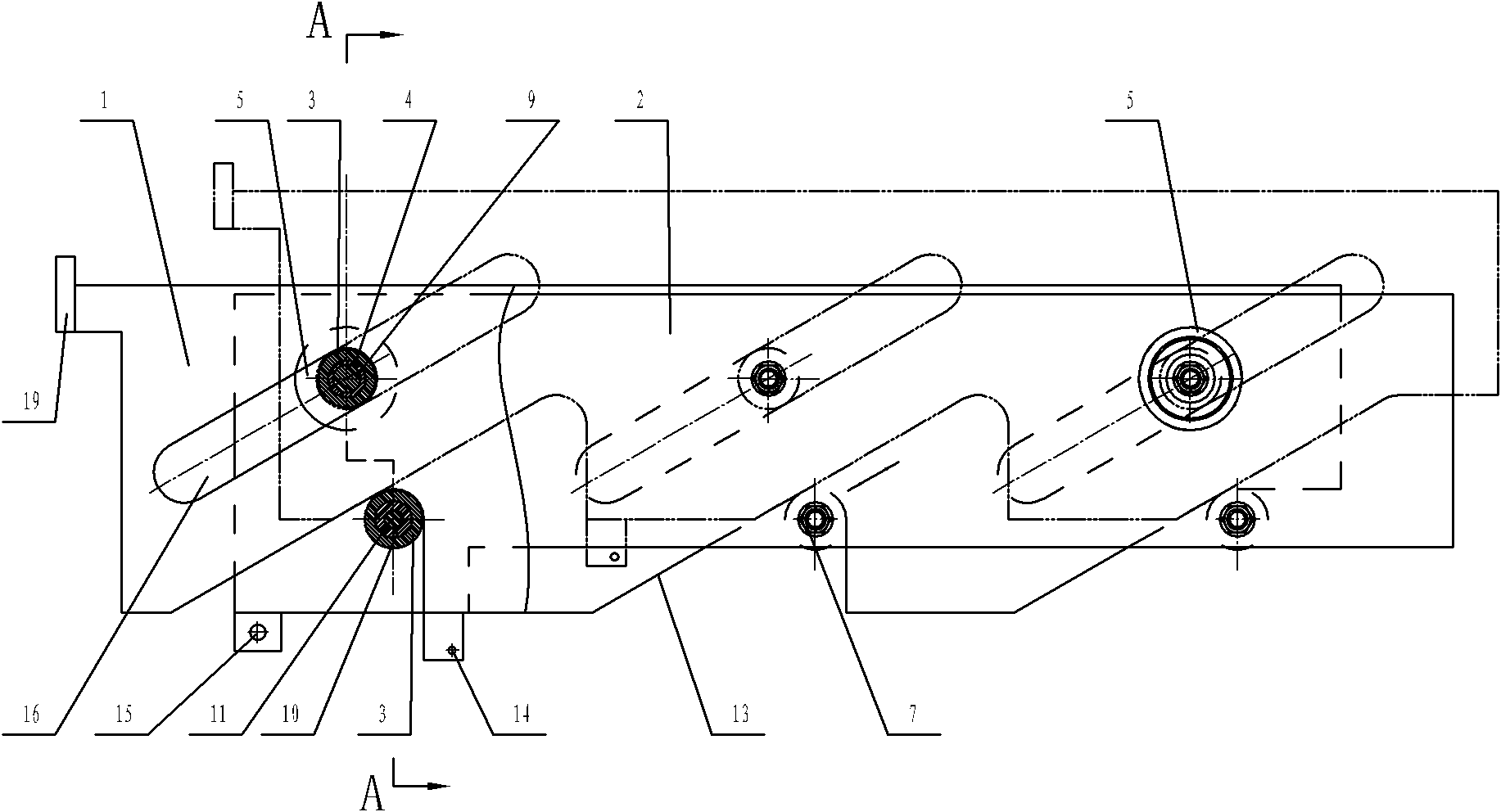

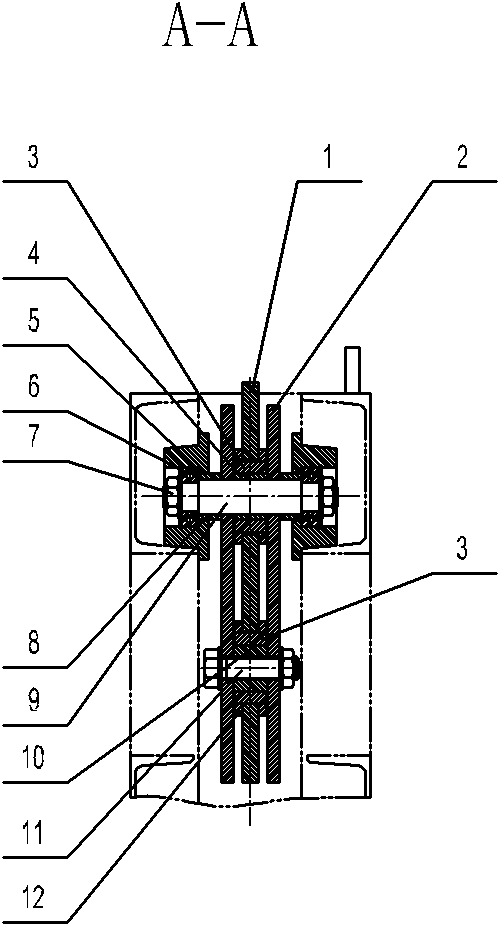

[0021] Such as figure 1 , figure 2 As shown, the present invention is a feeding and lifting mechanism of a through-type shot blasting cleaning machine, which includes two side plates 2 . The two side plates 2 are fixedly connected together by at least three sliding sleeve shafts 11 that are not on the same straight line, and a supporting plate 1 is arranged between the two side plates 2 . An inclined slideway is provided on the supporting plate 1 , and the slideway is slidably fitted on the sliding sleeve shaft 11 . Pulling the pallet 1, the pallet 1 moves on the sliding sleeve shaft 11 through the slideway to cause the pallet 1 to rise and fall.

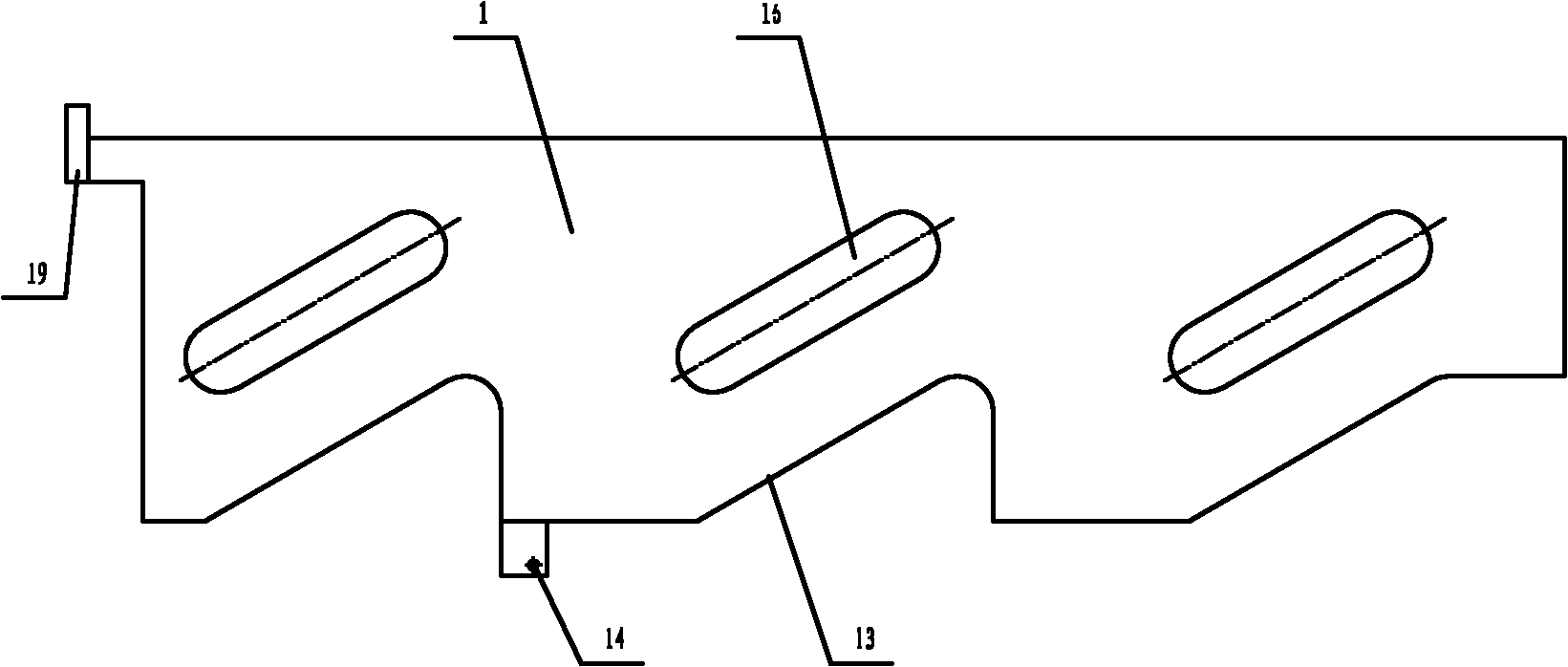

[0022] Such as image 3 As shown, the pallet 1 is an approximately rectangular plate with a slideway on it. One form of the slideway is three parallel round holes 16 arranged in the middle o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap