Safety air bag shell

A technology for airbags and shells, applied in the field of airbag shells, which can solve the problems of airbag module performance degradation, increased mold difficulty, and abnormal noise of airbag modules, and achieves process saving and development of riveting molds, simple processing, and reduced connections point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

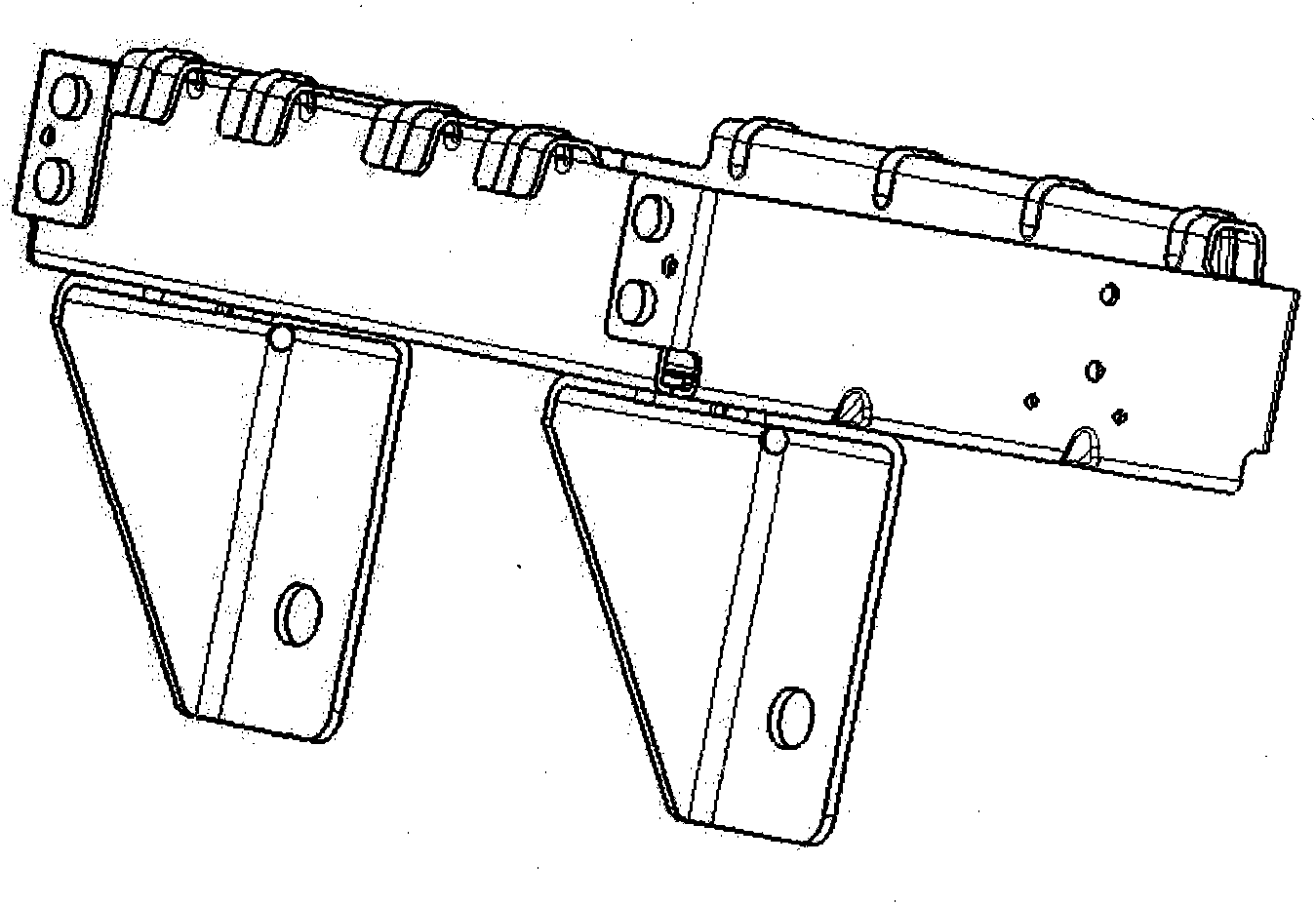

[0032] See attached Figure 5 , taking an example of adding a piece of flanging to the original lower bracket below the housing body 4, so that the lower bracket 10 is approximately Y-shaped, and the lower bracket 10 and the housing body 4 are added without increasing the thickness and size of the material. effective contact area, thereby increasing the support strength of the lower bracket 10.

Embodiment 2

[0034] See attached Figure 6 , as an example, adding two pieces of flanging to the original lower bracket under the housing body 4 can better play a supporting role, and there is no need to worry about the lower bracket 10 being biased to the side of the housing body 4, causing the housing The other side of the main body is prone to overturning. While increasing the support strength, it also takes into account the role of balance. According to this design principle, the following three schemes were tested:

[0035] Option One

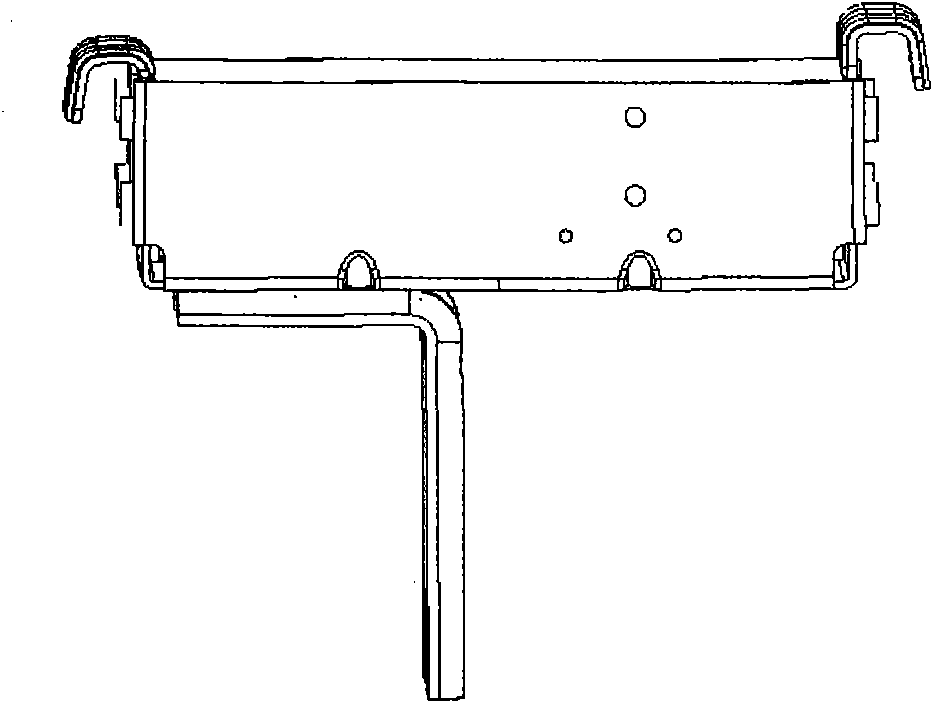

[0036] See attached Figure 7 According to the scheme 1, the passenger side airbag module includes a housing body 4, a front bracket 7, a rear bracket 8 and two lower brackets 10, and the airbag module fixes the front and rear brackets 7 and 8 on the On the instrument panel, it is connected to the cross member 9 of the vehicle body through two M8 bolts, and the horizontal plane 1 of the lower bracket is connected to the shell body 4 by riveting. Cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com