Anti-creep device of track running vehicle and track crane

A rail operation and crane technology, applied in the field of anti-climbing devices and rail cranes, can solve the problems of high power consumption, failure to prevent anti-climbing, and wheel brakes not being able to completely and effectively brake, and achieve low power consumption. , easy operation, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

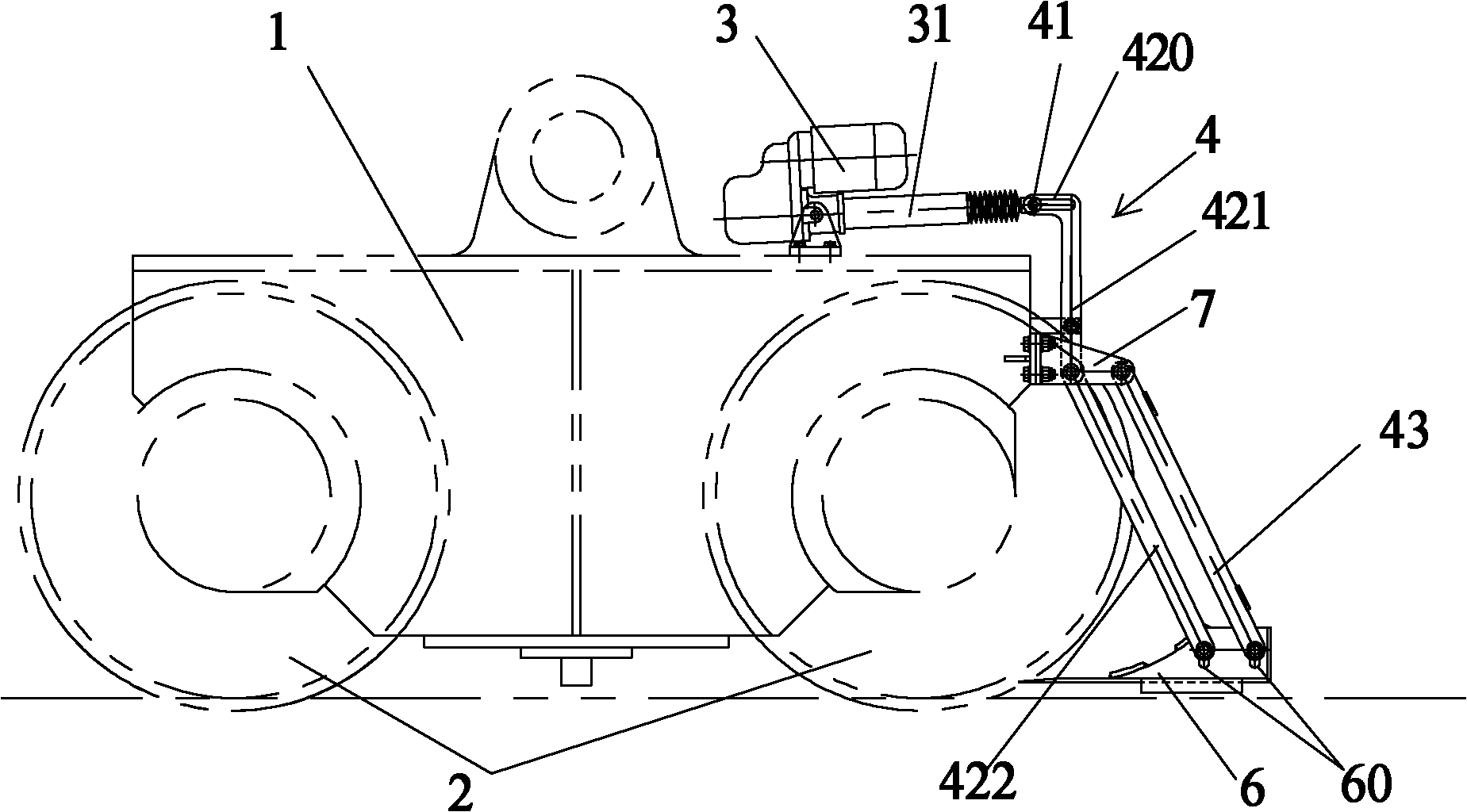

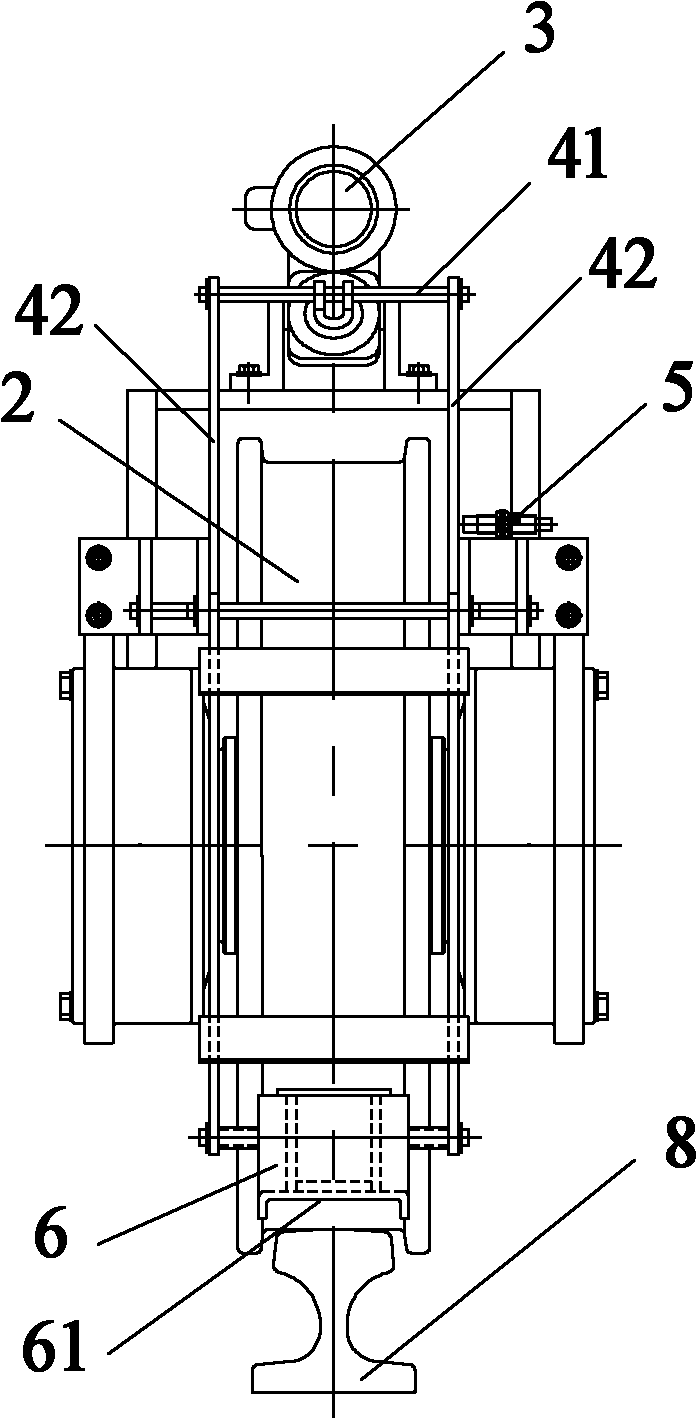

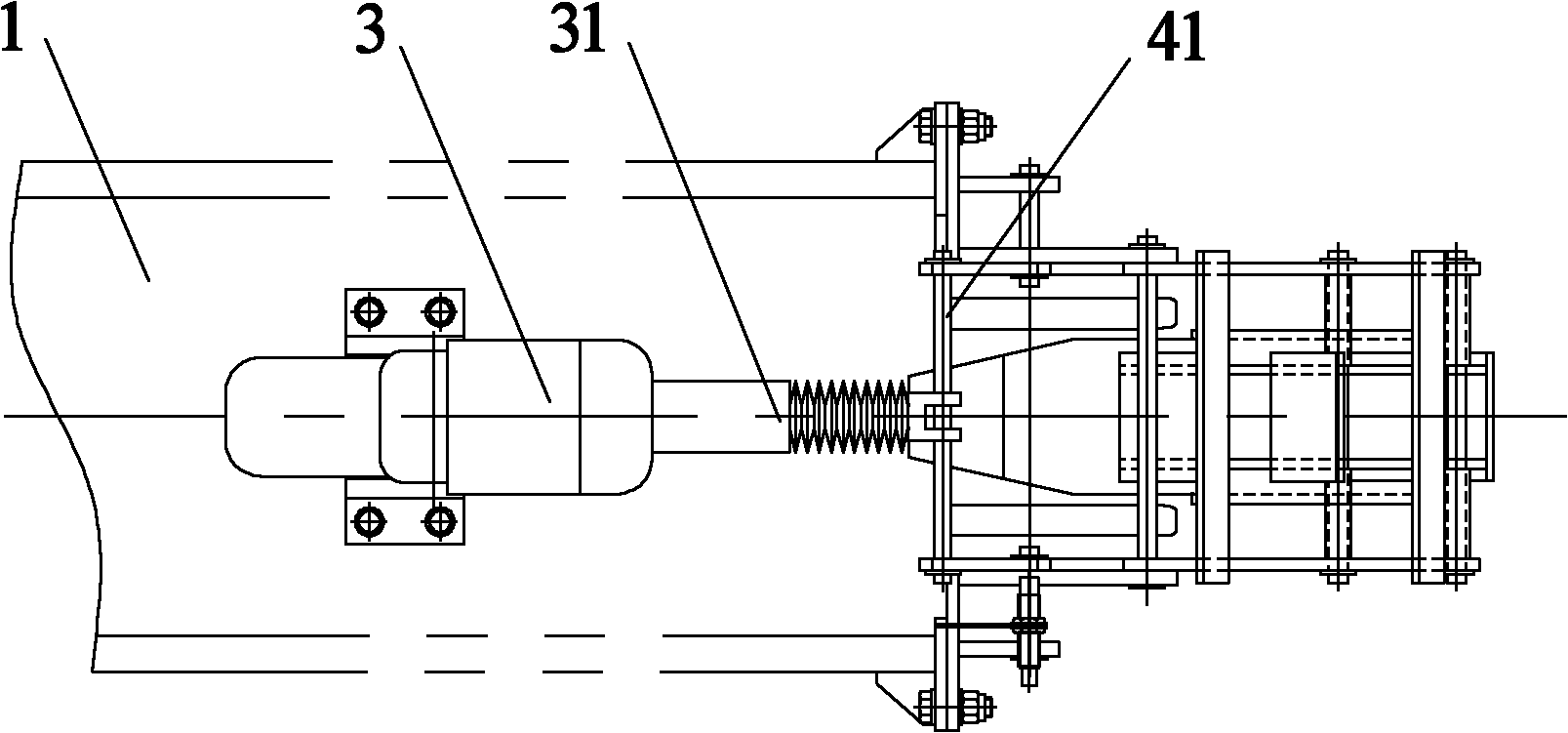

[0027] see Figure 1 to Figure 5 , shows an anti-climbing device for a rail running vehicle according to the present invention. In this embodiment, the rail running vehicle takes a rail crane as an example. As shown in the figure, the anti-climbing device includes: an actuator controlled by a circuit , in response to the first control signal and the second control signal of the circuit (hereinafter referred to as the control circuit of the actuator), respectively perform the first action and the second action; the push rod 31 is connected with the actuator, and executes the first Stretch out during the action, and retract when the actuator executes the second action; the transmission rod mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com