Outer cylinder barrel of shock absorber

A technology of outer cylinder and shock absorber, which is applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of only being treated as waste products, high product cost, rework and repair welding, etc., and achieve saving Environmental protection investment, low manufacturing and testing costs, and the effect of saving man-hours and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

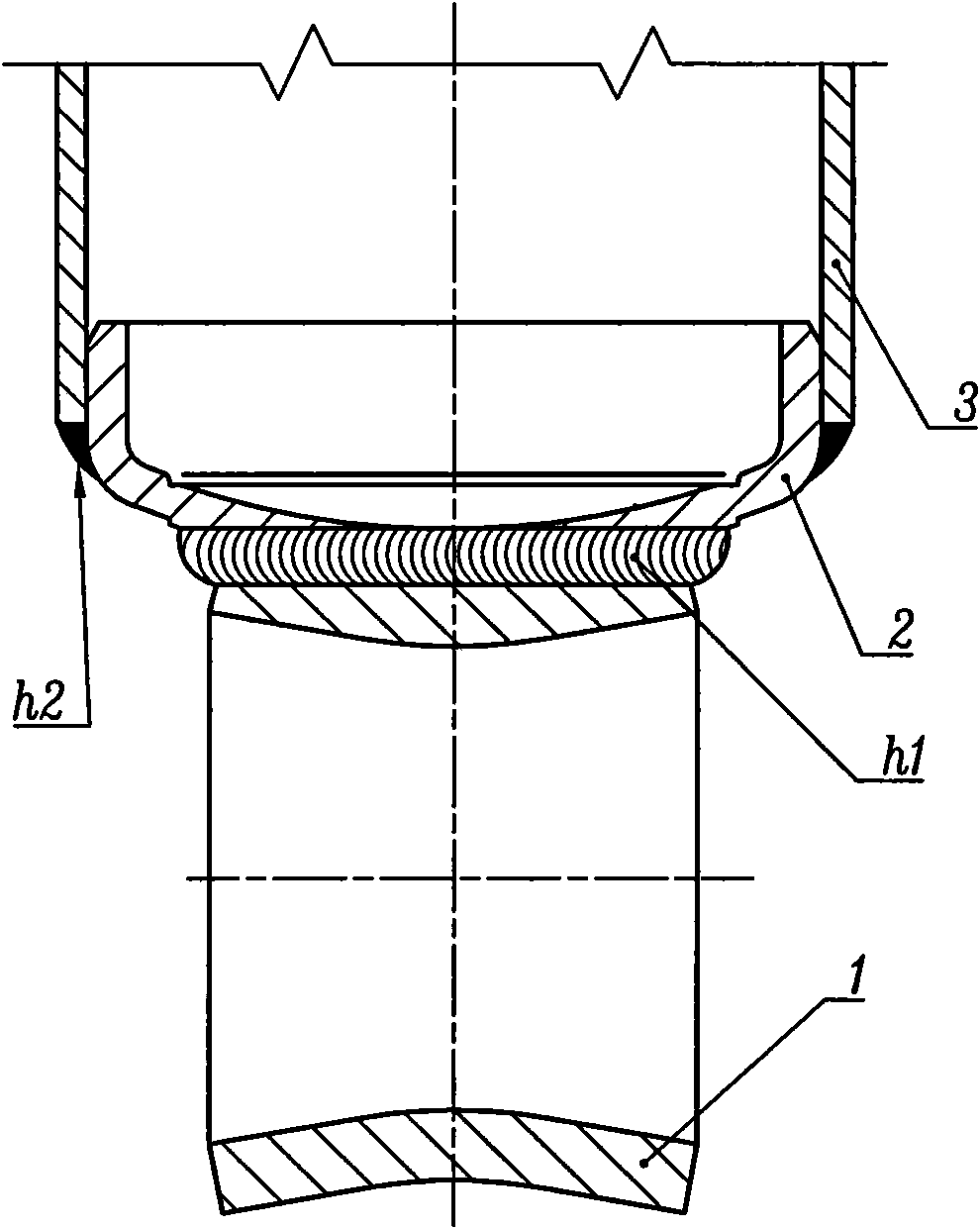

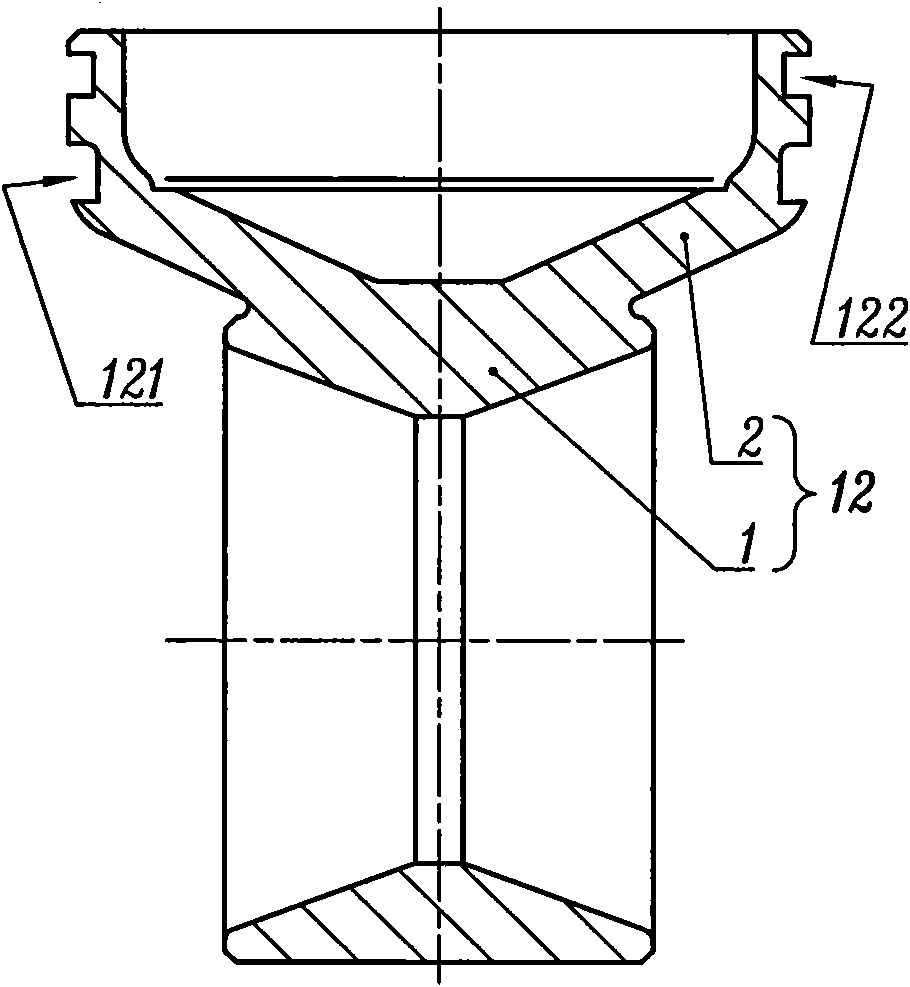

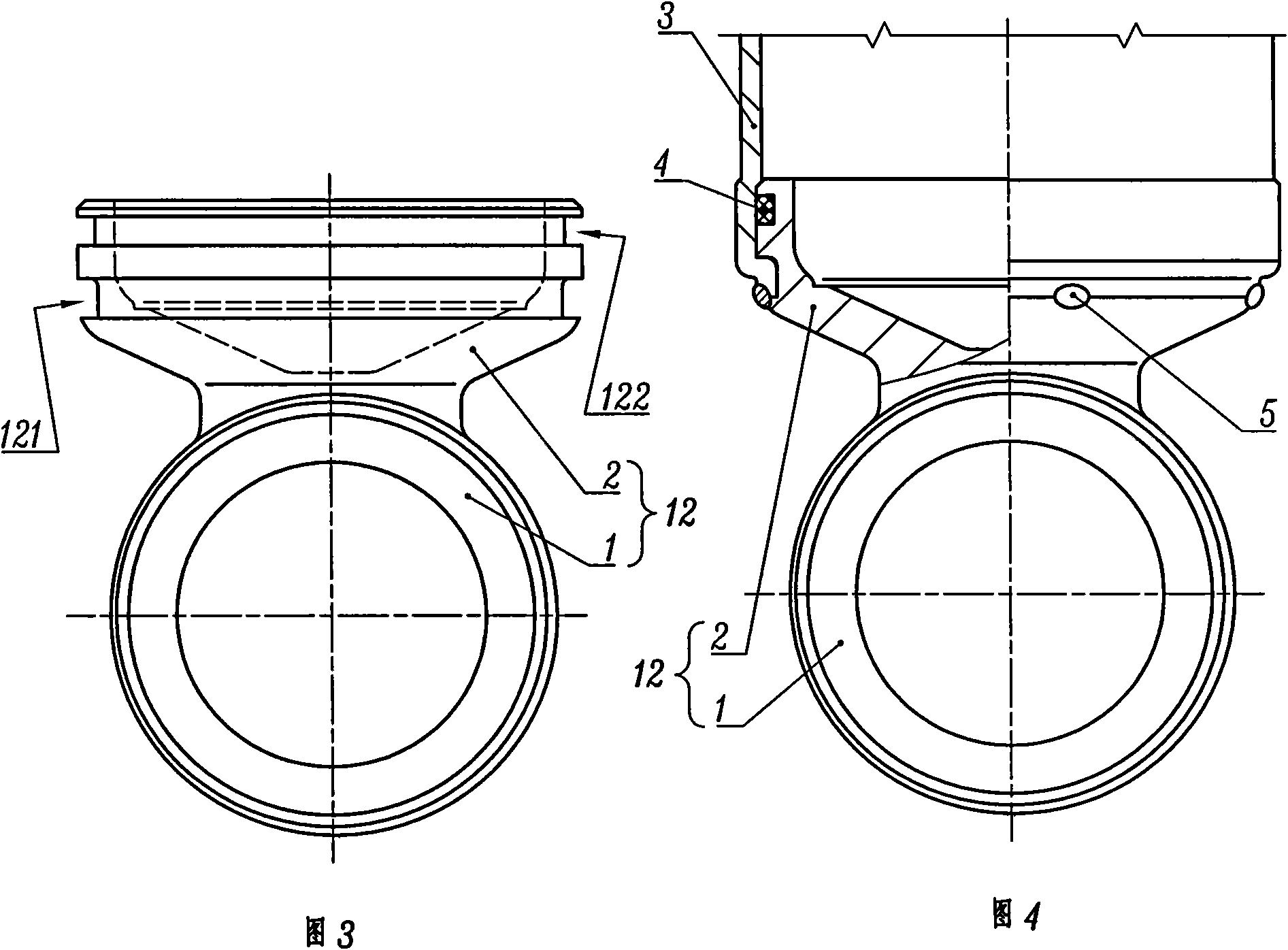

[0012] A kind of outer cylinder tube of shock absorber, (reference figure 2 , 3 ) The outer cylinder includes a cylinder body 3 , a head 2 sealingly connected to the cylinder body 3 and a suspension ring 1 fixedly connected to the lower part of the head 2 . In the present invention, there is a ring groove 122 on the outer periphery of the sealing head 2, and there is a ring groove 121 below the groove 122; (refer to Figure 4 ) The cylinder body 3 in the present invention is sealed with the head 2 with the lower end of the cylinder body 3 fastened in the buckle groove 121 after the seal ring 4 is installed in the seal ring groove 122 .

[0013] Further speaking, in order to improve the reliability of using the present invention in heavy-duty vehicles (load trucks, large passenger cars, etc.), (refer to Figure 4 ) in the state that the lower end of the cylinder body 3 is fastened in the buckle groove 121, its fastened side is reinforced by spot welding, and its welding spot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com