Fully-degradable agricultural biological intelligent mulching film and preparation method therefor

A fully degradable and agricultural technology, applied in botany equipment and methods, chemical instruments and methods, applications, etc., can solve the problems of high cost, high cost of working hours, increase of soil moisture, etc., achieve high cost, save working hours, increase The effect of soil moisture in farmland

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

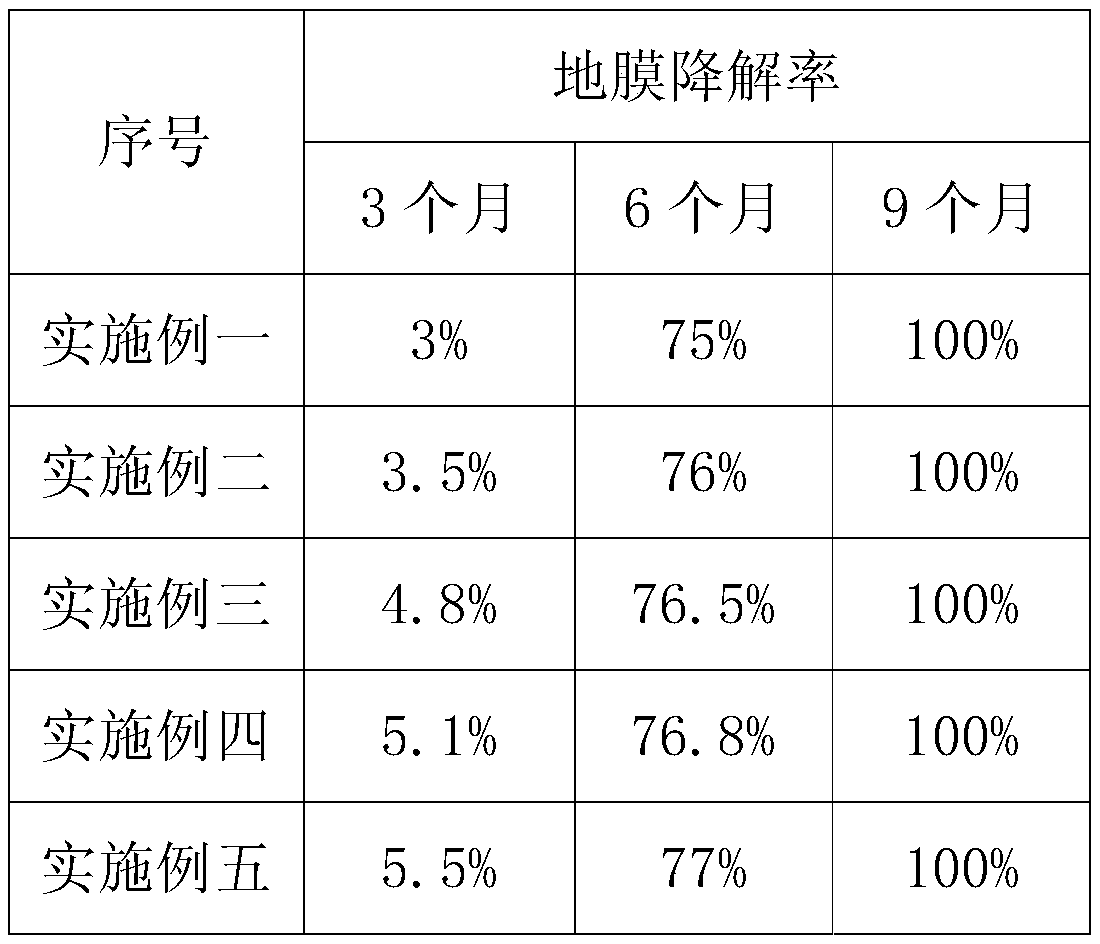

Examples

Embodiment 1

[0025] Weighing 0.5 parts of modified starch, 0.6 parts of polyvinyl alcohol, 0.4 parts of emulsifier, 0.3 parts of carboxymethyl cellulose, 0.2 parts of pH regulator, 0.2 parts of natural latex and 97.8 parts of distilled water . The modified starch is phosphate starch, the emulsifier is xanthan gum, and the pH regulator is trisodium phosphate. Add the weighed modified starch and polyvinyl alcohol into distilled water, heat to 80°C and stir evenly. After the mixed liquid in step a) is cooled to room temperature, add the weighed emulsifier and carboxymethyl cellulose, heat to 70°C, keep warm in a water bath for 60min and keep stirring. Then, add weighed natural latex and pH regulator to the mixed solution prepared in step b), and stir at a constant speed to emulsify the mixed solution under the action of shear force to obtain a uniform, stable and viscous liquid finished product preparation.

Embodiment 2

[0027] Weighing 0.75 parts of modified starch, 0.7 parts of polyvinyl alcohol, 0.5 parts of emulsifier, 0.4 parts of carboxymethyl cellulose, 0.25 parts of pH regulator, 0.25 parts of natural latex and 97.15 parts of distilled water . Others are the same as embodiment one.

Embodiment 3

[0029] Weighing 1 part of modified starch, 0.8 part of polyvinyl alcohol, 0.6 part of emulsifier, 0.5 part of carboxymethyl cellulose, 0.3 part of pH regulator, 0.3 part of natural latex and 96.5 parts of distilled water . Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com