Antibacterial rubber roll

A rubber roller and rubber technology, which is applied in the field of antibacterial rubber rollers, can solve the problems of surface dirtying and affecting use, and achieve the effect of reducing the frequency of replacement, saving labor costs and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

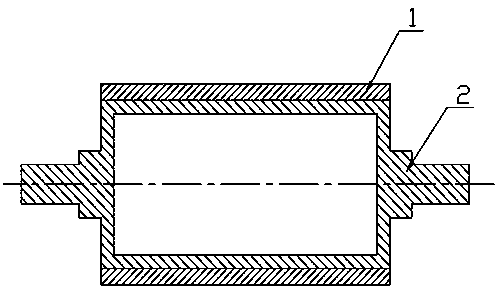

[0014] see figure 1 , providing an antibacterial rubber roller, comprising a rubber roller surface 1 and a roller core 2, the surface of the roller core 2 is bonded with the rubber roller surface 1, the thickness of the rubber roller surface 1 is 4mm, and the rubber roller The composition of surface 1 is: in parts by mass, 100 parts of fluororubber, 27 parts of thermal cracking carbon black, 1.5 parts of lead stearate, 2 parts of accelerator NA-22, 5 parts of magnesium oxide, and 3 parts of vulcanizing agent S-3 , 1.1 parts of chlorhexidine acetate, 2.5 parts of copper rosinate, and 0.7 parts of organic silicon.

Embodiment 2

[0016] Provide a kind of antibacterial rubber roll, comprise rubber roll surface and roll core, the surface of described roll core is bonded with described rubber roll surface, the thickness of described rubber roll surface is 3mm, and the composition of described rubber roll surface is: In parts by mass, 100 parts of fluororubber, 33 parts of thermal cracking carbon black, 0.5 part of lead stearate, 1 part of accelerator NA-22, 7 parts of magnesium oxide, 4 parts of vulcanizing agent S-3, 0.9 part of chlorhexidine acetate , 3 parts of copper rosinate, 0.5 part of organic silicon.

Embodiment 3

[0018] Provide a kind of antibacterial rubber roll, comprise rubber roll surface and roll core, the surface of described roll core is bonded with described rubber roll surface, the thickness of described rubber roll surface is 6mm, and the composition of described rubber roll surface is: In parts by mass, 100 parts of fluororubber, 23 parts of thermal cracking carbon black, 0.5 part of lead stearate, 3 parts of accelerator NA-22, 7 parts of magnesium oxide, 2 parts of vulcanizing agent S-3, 1.2 parts of chlorhexidine acetate , 2 parts of copper rosinate, 1 part of organic silicon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com