Round compressing process of stranded aluminum conductor

A compacting process, a technology for aluminum conductors, used in cable/conductor manufacturing, manufacturing extensible conductors/cables, forming tools, etc., can solve problems such as difficult to repair and easy to break wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The compression process method stretching embodiment of the present invention is described in detail below:

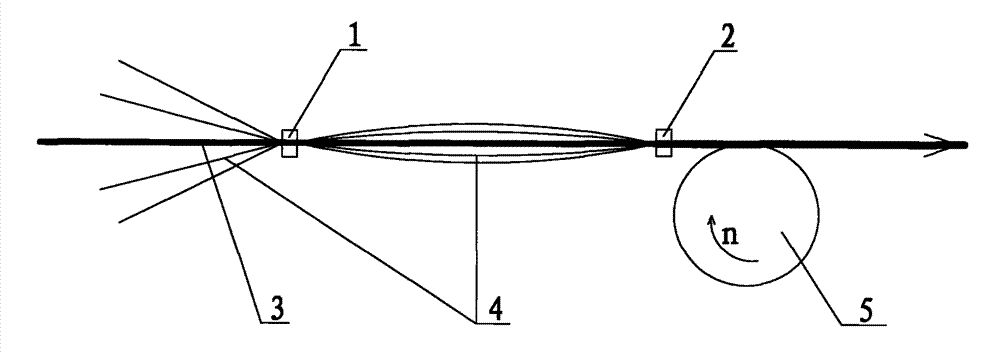

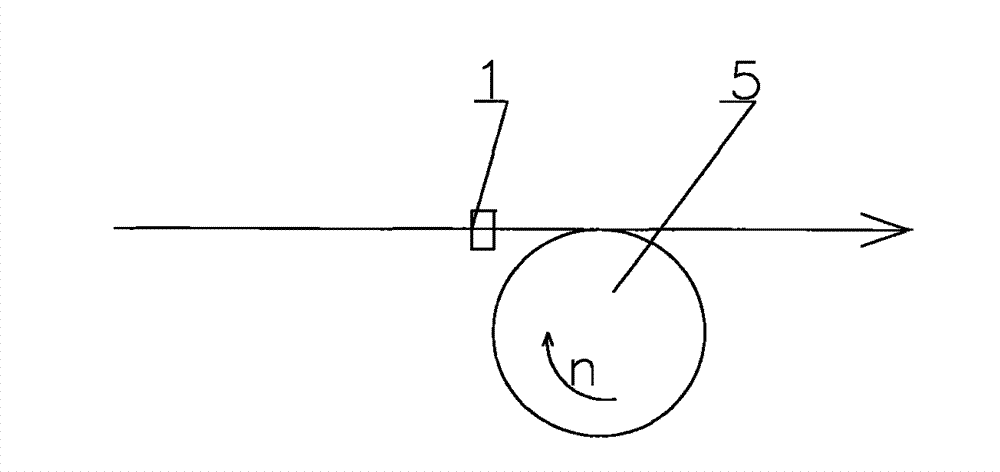

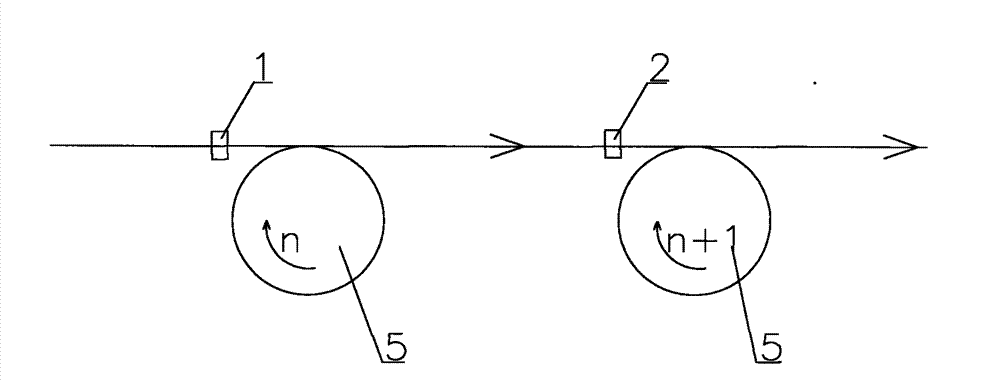

[0012] Such as figure 1 As shown, the preferred embodiment of the present invention is: the present invention is used on the multiple aluminum monofilament stranded wire layers of more than six layers of stranded aluminum conductor circular compression processing, and the drawing dies 1 and 2 are cemented carbide drawing Die or diamond coated drawing die. The first stretching die 1 is installed at the doubling die of the stranding machine, and the second stretching die 2 is installed at a position about 1.5 meters away from the first stretching die 1. If the installation distance between the two dies is too short, it will make it inconvenient to repair the broken wire. In addition, when a single wire breaks, the broken end may run past the second drawing die 2. If it is too long, the installation of the stranding equipment will be inconvenient. Location does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com