Method for manufacturing sole structure from braided fabric and sole structure

A technology of weaving and weaving, used in the field of making shoe sole structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Detailed description and technical contents of the present invention are as follows with regard to coordinating accompanying drawings now:

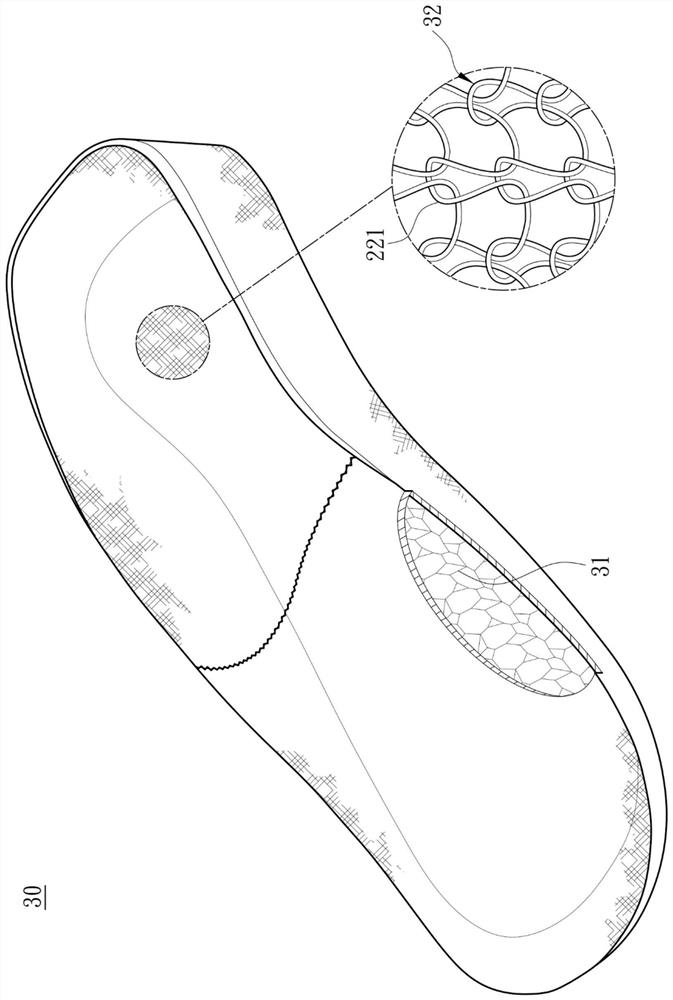

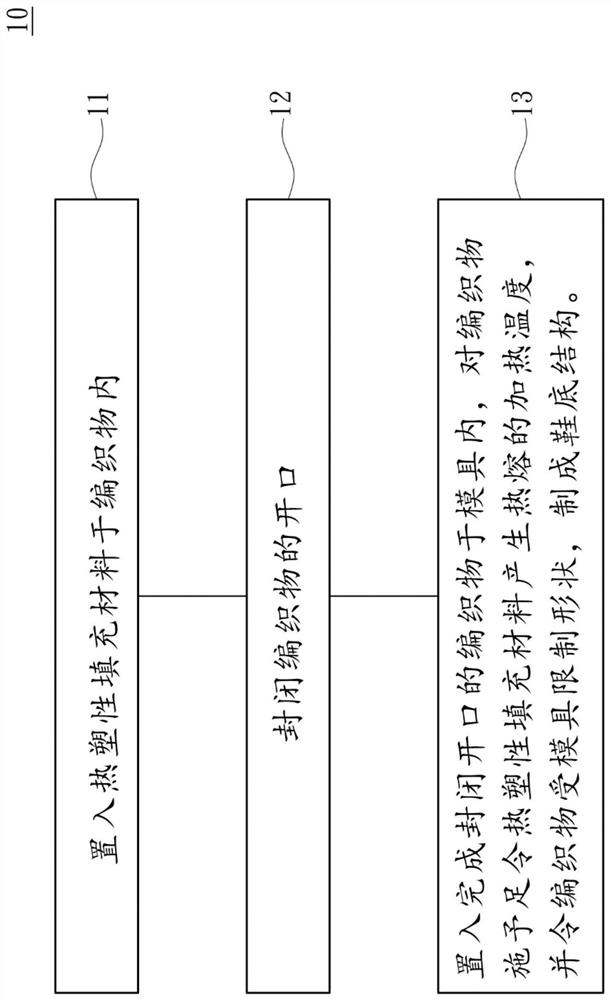

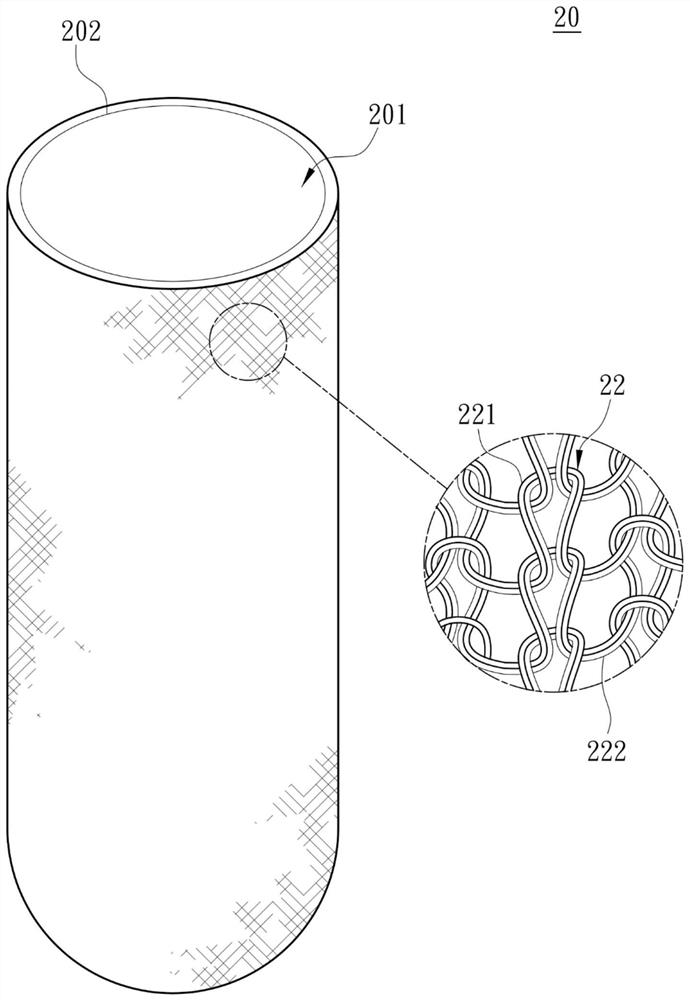

[0059] see Figure 1 to Figure 3 The present invention provides a method 10 for fabricating a shoe sole structure. Firstly, the braid 20 referred to herein is formed with a space 201 and an opening 202 communicating with the space 201 . Further, this braided fabric 20 can be made of a sock embryo (as image 3 painted), or fabrics woven by pocket weaving techniques, or fabrics formed by stitching multiple cloth materials. Moreover, the braided fabric 20 of the present invention is not used to form the base of the sole structure 30 , and the base of the sole structure 30 is still realized by a compressible elastic body 31 . With this in mind, continue to describe the method 10 of the present invention, the method 10 includes the following steps:

[0060] Step 11: placing a thermoplastic filling material 21 in the space 201 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com