Nodule removal maintenance system and maintenance method for removing coke nodules in carbonization chamber

A carbonization chamber and nodule technology, which is applied in coke ovens, furnaces to prevent/remove deposits, and petroleum industry, etc., can solve the occupational diseases of respiratory tract of construction workers, uneven expansion of furnace wall bricks, and long time required for manpower to break tumors. and other problems, to achieve the effect of easy promotion and use, good removal of nodules, and avoidance of inhalation of toxic gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

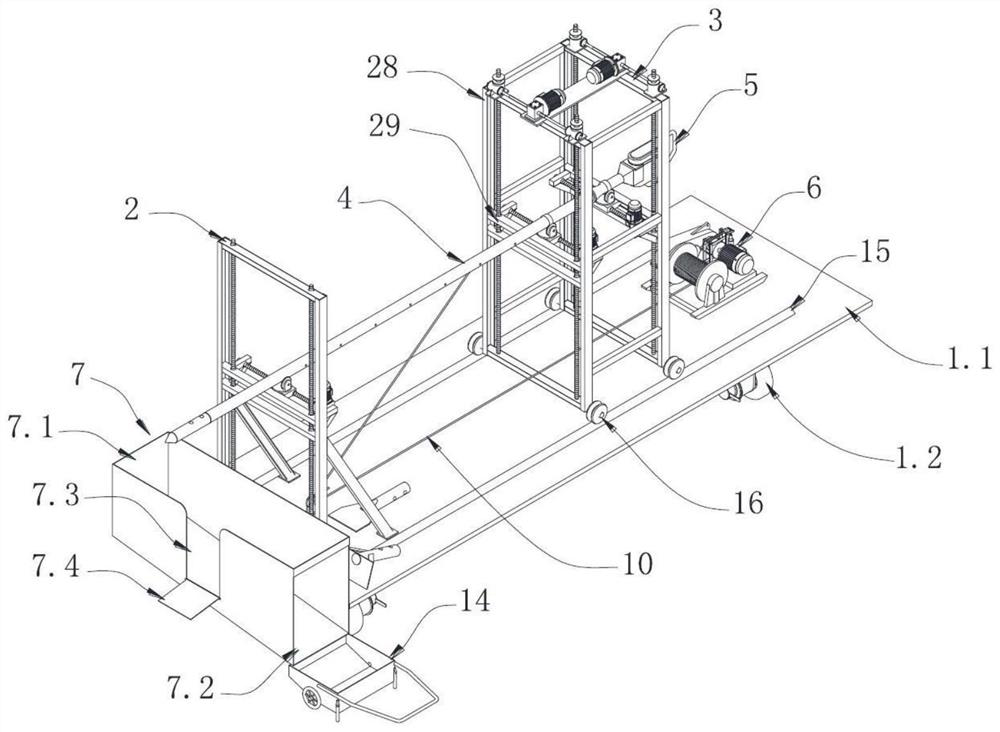

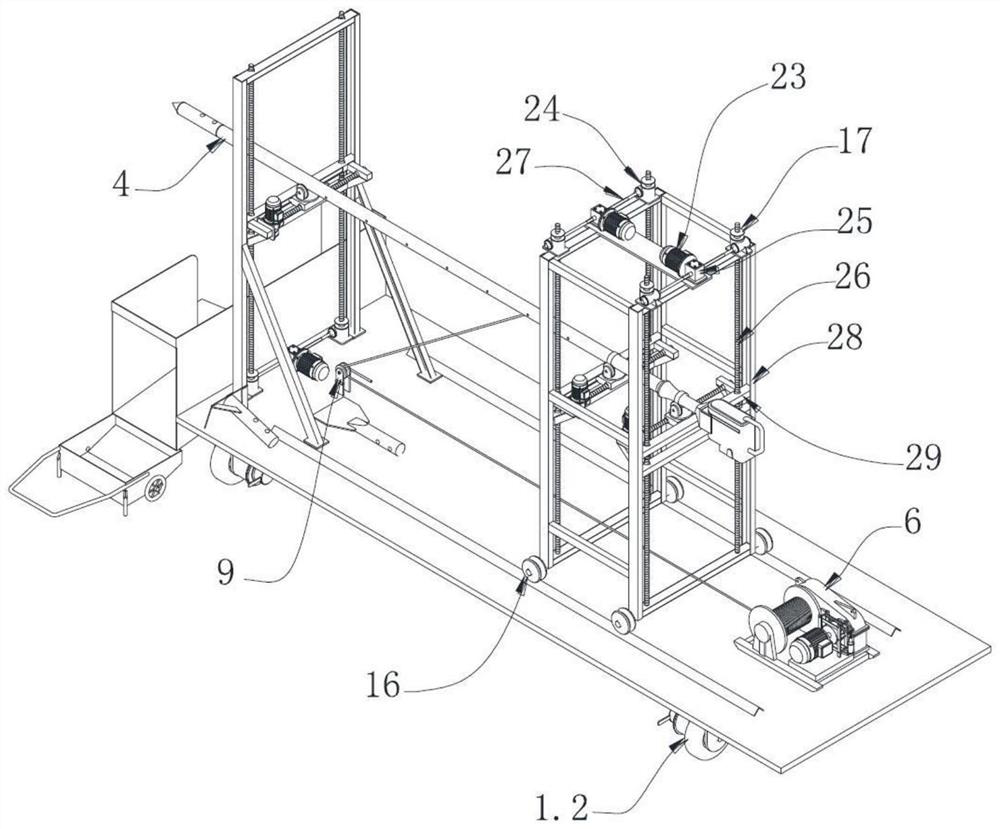

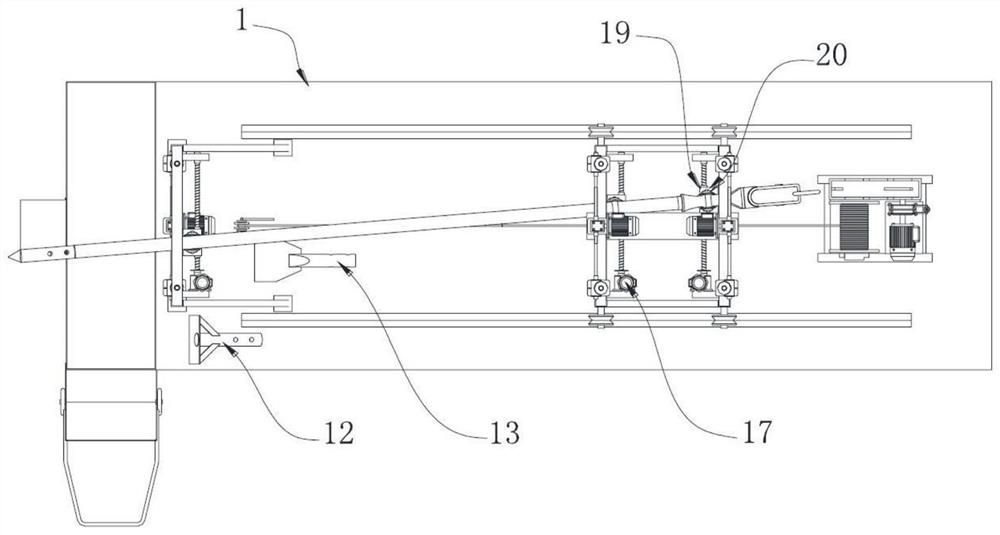

[0059] see Figure 1-Figure 12 , a tumor removal and maintenance system for removing coke nodules in a carbonization chamber, which includes a construction vehicle 1 , a fixed pipe support control frame 2 , a mobile pipe support control frame 3 , a long rod 4 , a vibration device 5 and a hoist 6 . The construction vehicle 1 includes a platform 1.1 and a drive wheel 1.2 located under the platform 1.1. The fixed pipe support control frame 2 is placed on the platform 1.1 of the construction vehicle 1; the mobile pipe support control frame 3 is also placed on the platform 1.1 of the construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com