Thermal-insulation masonry wall

A masonry and thermal insulation technology, applied in thermal insulation, building components, walls, etc., can solve the problems of cutting corners, complicated construction, short life and other problems, and achieve the effects of high masonry strength, good thermal insulation performance and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

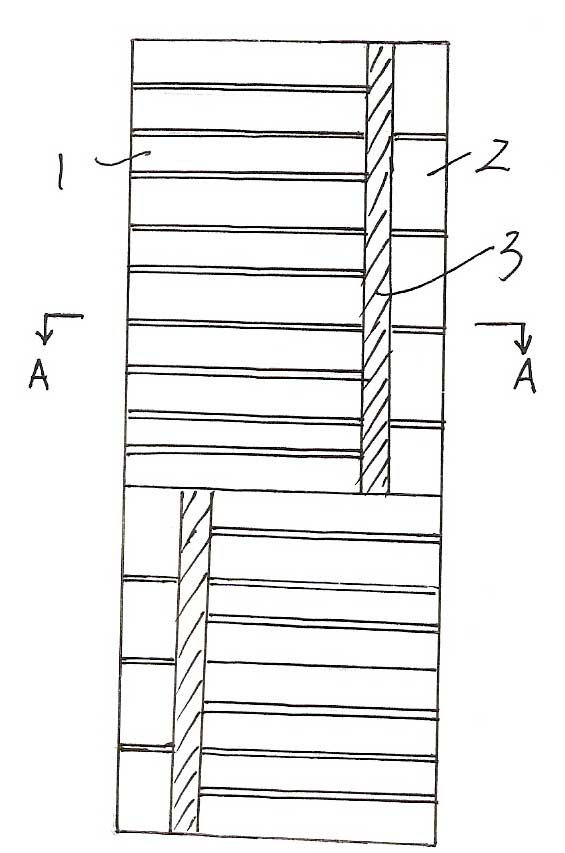

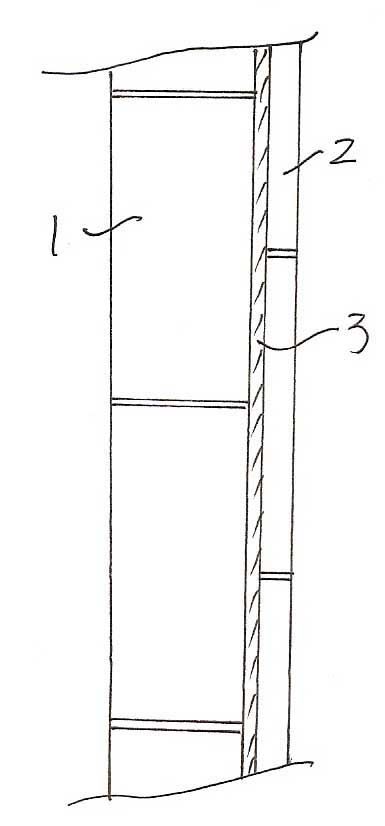

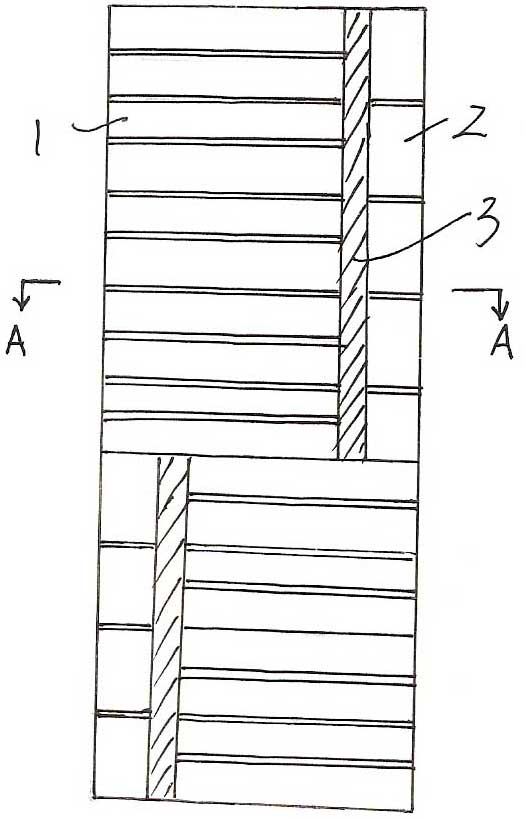

[0017] A thermal insulation masonry, comprising a wall, the wall is built according to the method of laying along, the wall includes inner and outer bricks 1, 2, and an insulating material layer 3 is arranged in the cavity between the inner and outer bricks, and the inner , The outer brick body is in the form of a wider inner brick body and a narrower outer brick body or a narrower inner brick body and a wider outer brick body in the thickness direction of the wall body.

[0018] In each batch of bricks in the wall, the insulation material layer 3 between the inner and outer bricks is in a straight line in section.

[0019] In each batch of bricks in the wall, the bricks with a wider width in the thickness direction of the wall are in the form of superimposing two layers of bricks, and the bricks with a narrower width in the thickness direction of the wall are one layer of vertical bricks. form (of course other suitable forms may also be used).

[0020] In each batch of brick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com