Three-dimensional fine-adjustment worktable for thread scanning meter

A workbench and measuring instrument technology, applied to measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of high cost, complex structure, and many parts, and achieve the effect of increasing accuracy and reducing pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

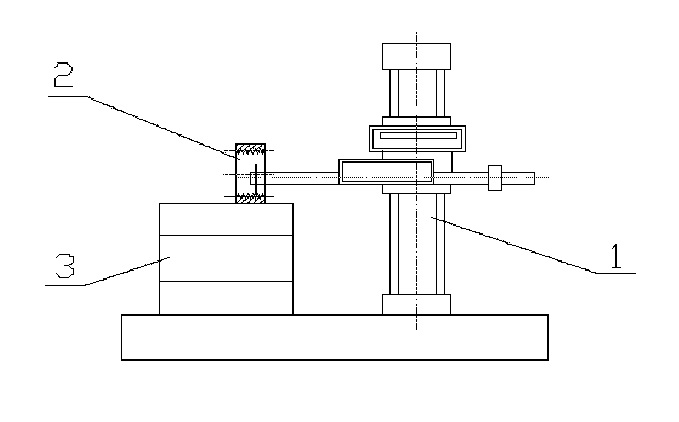

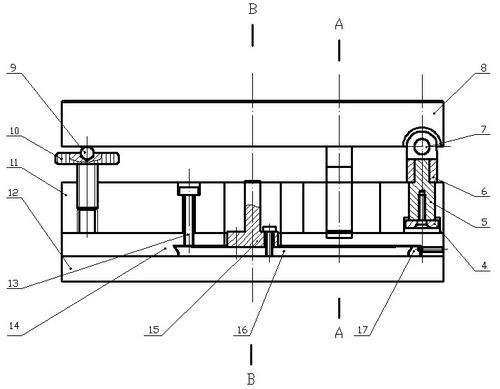

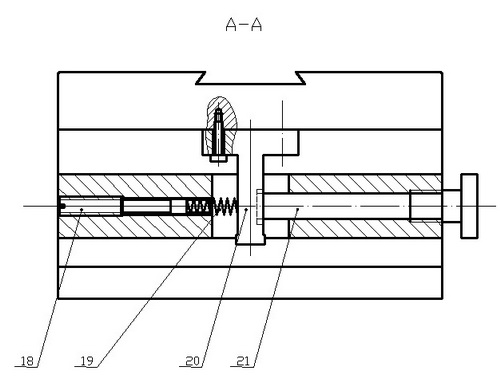

[0044] The total height of the three-dimensional fine-tuning worktable of the thread measuring instrument in this embodiment is 14 cm; the length is 30 cm, the width is 24 cm, and it is made of stainless steel. working status as figure 1 As shown, 1 is the thread measuring instrument, 2 is the measured part; 3 is the three-dimensional fine-tuning workbench. The three-dimensional fine-tuning table dedicated to the thread measuring instrument in this embodiment is divided into three layers from top to bottom: the upper layer rotates around the Y axis, the middle layer rotates around the Z axis, and the bottom layer moves linearly along the Y axis.

[0045] The upper workbench 8 is 30 cm long and 24 cm wide, and there is a dovetail-shaped groove on the upper part, which cooperates with the special vise for clamping the measured part 2, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com