Window roller blind

A rolling shutter and rolling spring technology, used in door/window protection devices, transportation and packaging, building components, etc., can solve the problem of not blocking the noise of the rolling shaft well enough, and achieve the effect of increasing the weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

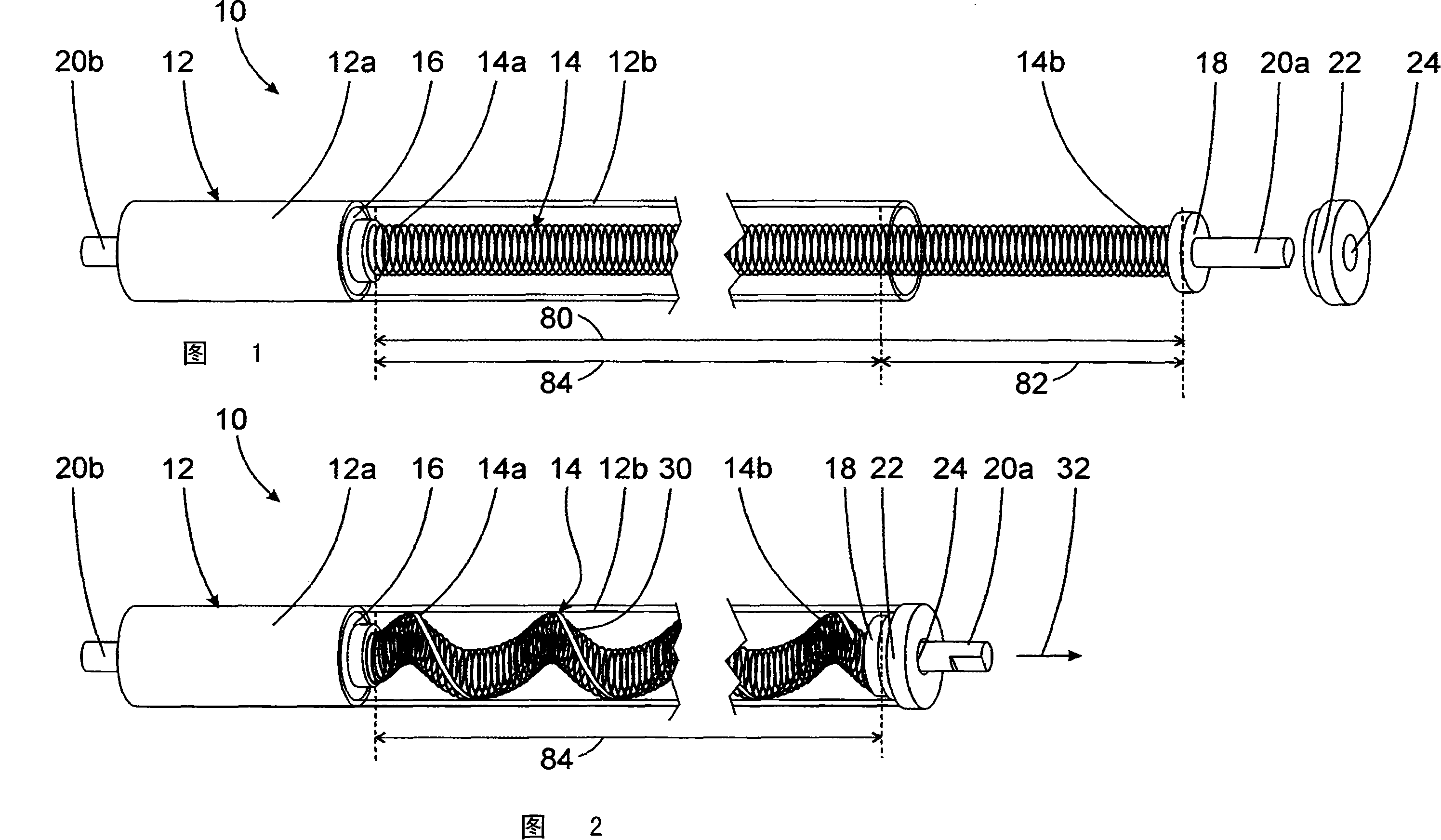

[0021] FIG. 1 shows a roller blind arrangement 10 , the main components of which are a roller shaft 12 and a roller spring 14 . The reel 12 is designed as a hollow tube, which is shown partially transparent in the illustrated embodiment for better understanding. The spool is used to accommodate the planar article in rolled form, where the planar article is not shown in the figures. A spring holder 16 is arranged in the reel 12 , which is connected to the reel 12 in a relatively non-rotatable manner on one side and to the first end 14 a of the coil spring 14 in a relatively non-rotatable manner. The spring holder 16 divides the spool into a springless section 12a and a spring containing section 12b.

[0022] In the unclamped state, the coil spring 14 has a length 80 which is longer than a length 84 of the spring receiving section 12 b by a length difference 82 . Arranged at the second end of the coil spring 14 is a fastening section 18 which is connected to the second end 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com