Automotive wiring harness conduction detection method

A detection method and wire harness detection technology are applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., which can solve problems such as poor interaction, incorrect wiring harness, and reduced operating efficiency, and achieve accurate and reliable detection data, simple implementation steps, and improved efficiency. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

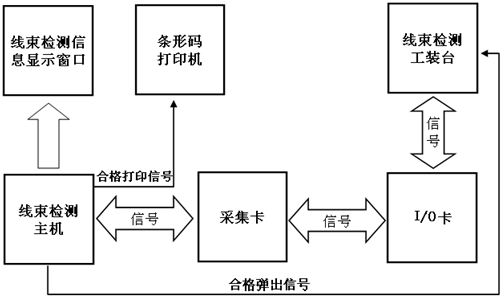

[0013] Such as figure 1 As shown, the detection system of the present invention is composed of six parts: wire harness detection tooling table, I / O card, acquisition card, wire harness detection host, detection information display window, and barcode printer; the wire harness is fixed on the detection tooling table, and the wire harness detection tooling table There is a jig connected with the wiring harness on the top, so that the wires in the wiring harness can be connected with the wiring harness detection tooling platform, and an interface connected with the conduction machine is provided, which is used with the input and output ports on the I / O card, commonly known as I / O ports. The dedicated wires are docked one by one, and a closed-loop circuit is formed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com