Experiment design and analysis method for most severe current stress born by thyristor used for converter valve

A technology of current stress and analysis method, which is applied in the direction of circuit breaker testing, single semiconductor device testing, etc. It can solve the problems of different thyristor current stress, unsatisfactory requirements, and inconsistent current waveforms, etc., and achieves simple implementation, easy adjustment, and simulation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention adopts the following sequence to realize the test design and process of the thyristor used in the converter valve to withstand the most severe current stress:

[0033] (1) Non-periodical triggering condition of the converter valve;

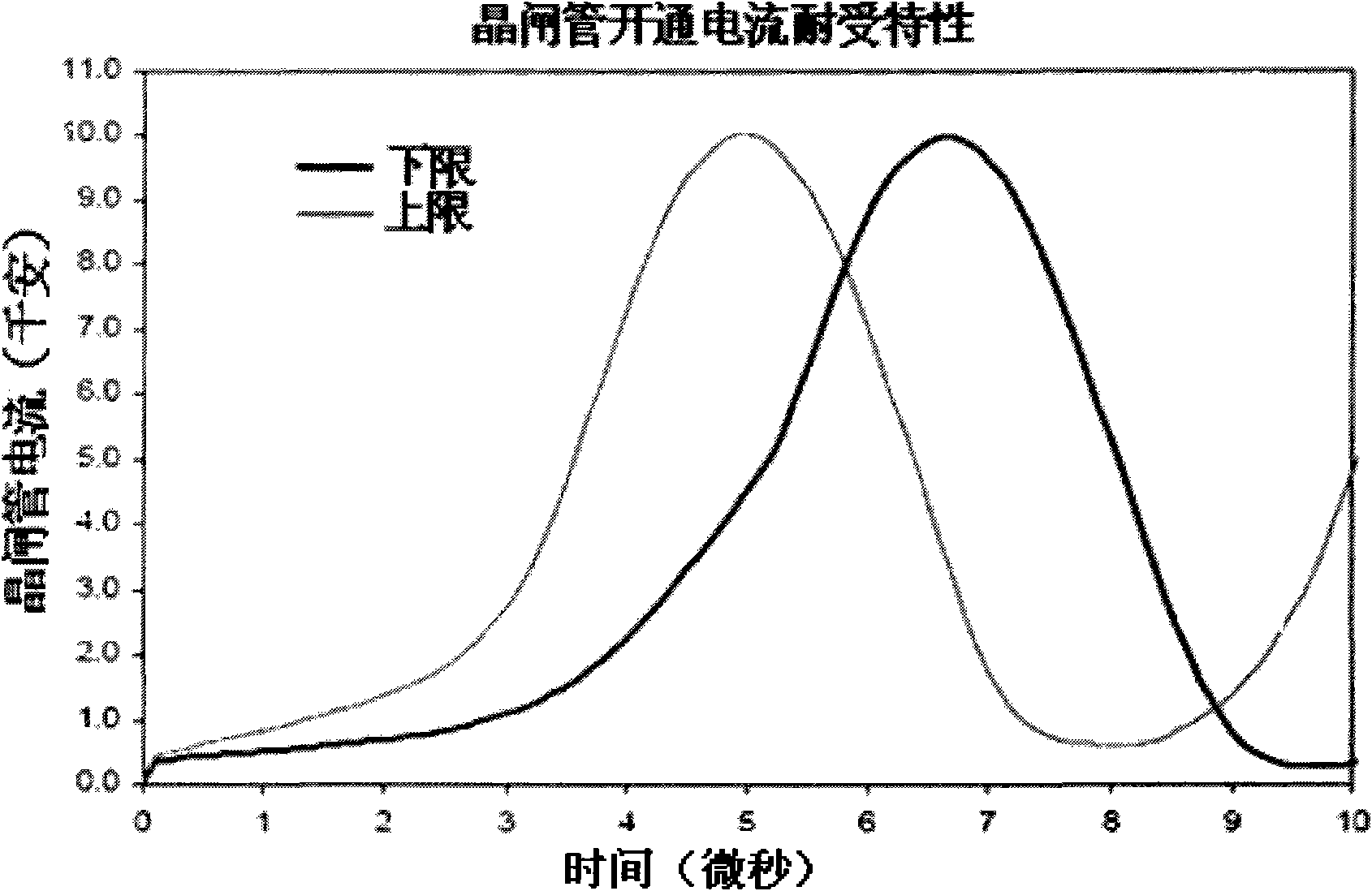

[0034] When the converter valve is subjected to non-periodic triggering conditions, the typical current waveform flowing through the thyristor is as follows: Figure 1 shown.

[0035] (2) Thyristor current test circuit;

[0036] The present invention names this test as the non-repetitive trigger current test, and the purpose is to produce and Figure 1Equivalent current stress, and the parameter adjustment of the test circuit should be simple and convenient, and the test object is a single thyristor.

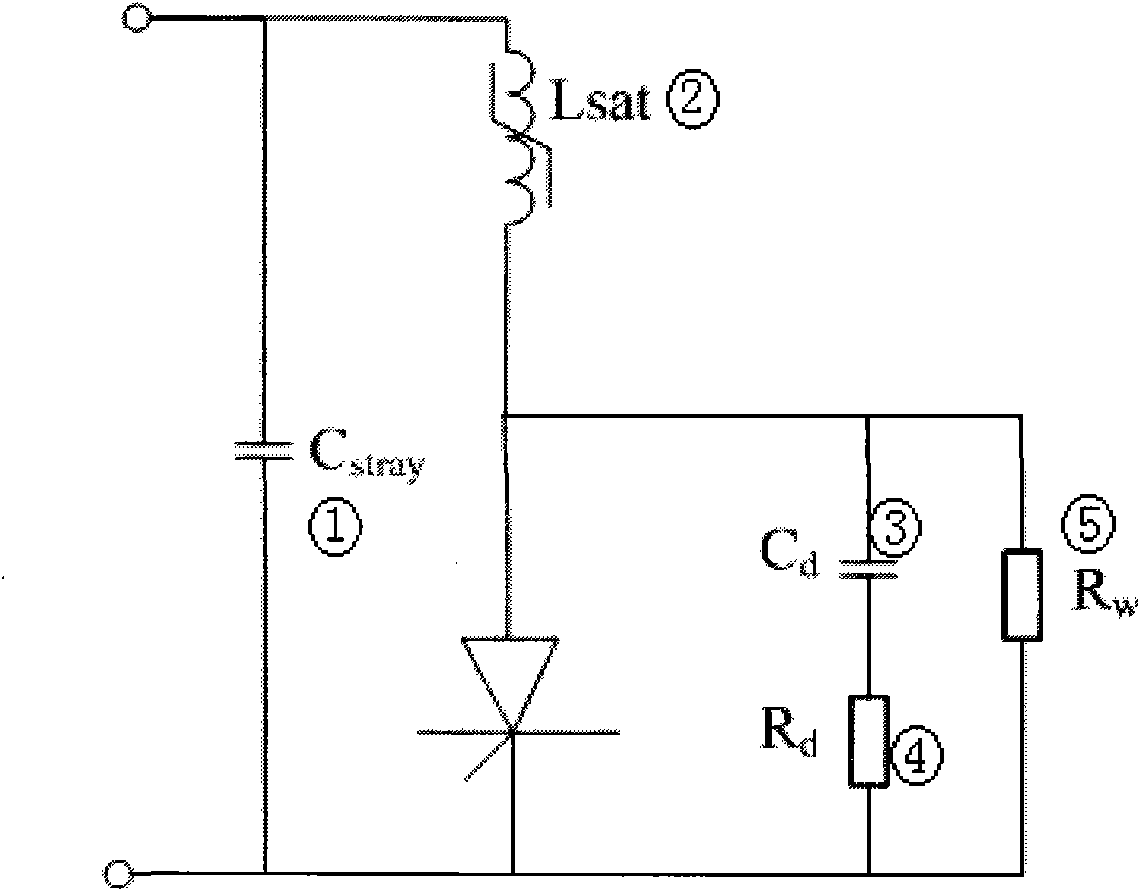

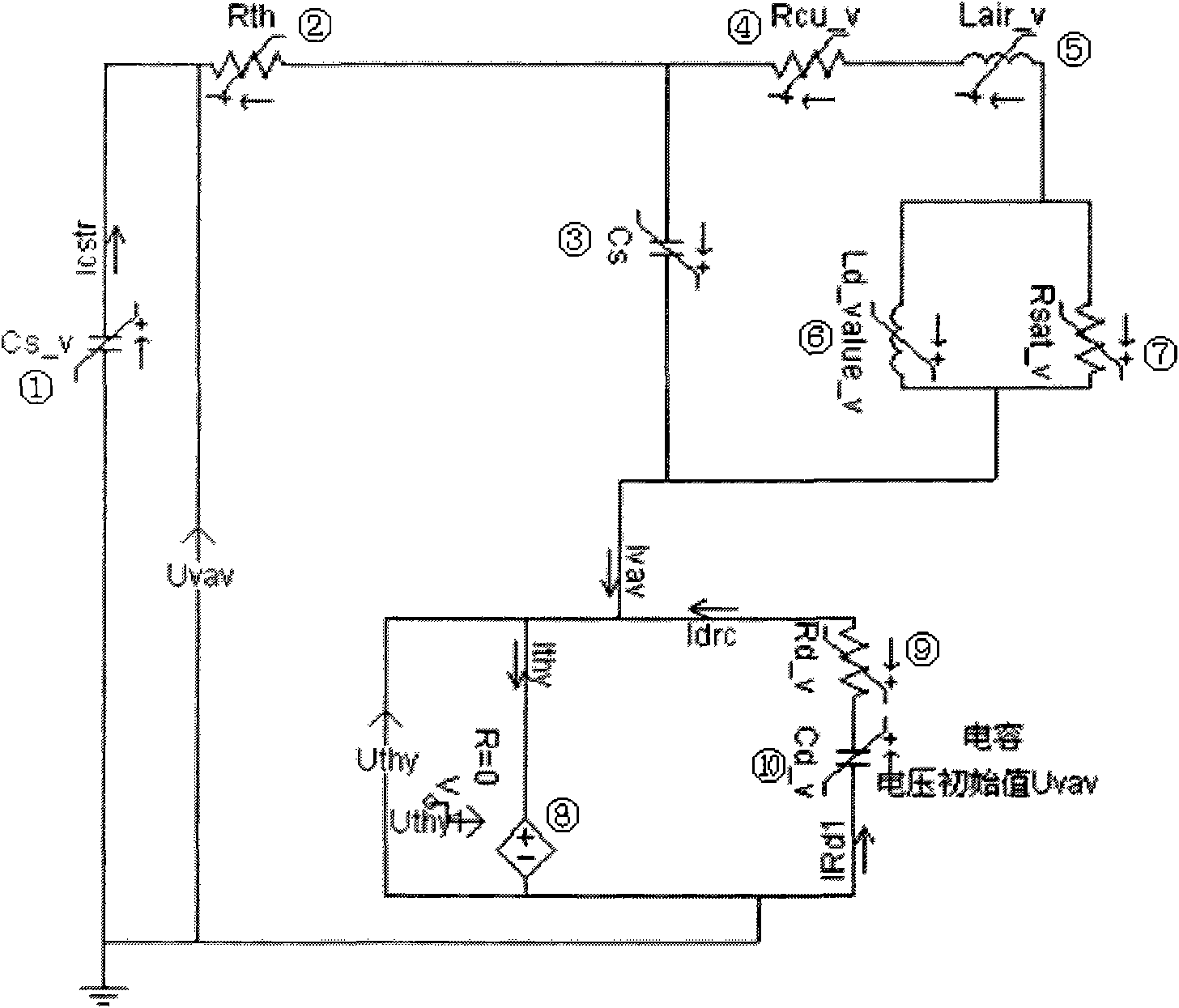

[0037] The schematic diagram of the test circuit is as Figure II shown. where the discharge capacitor C stray pre-charged to Uo, saturable reactor L sat It is equivalent to a saturated reactor connected to a sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com