Method for managing failure of facility

A technology of bad situations and management methods, applied in data processing applications, testing of machines/structural components, resources, etc., can solve problems such as difficult printer quantification, technical difficulties, and inference results without sufficient accuracy, and achieve sufficient accuracy and reliability sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

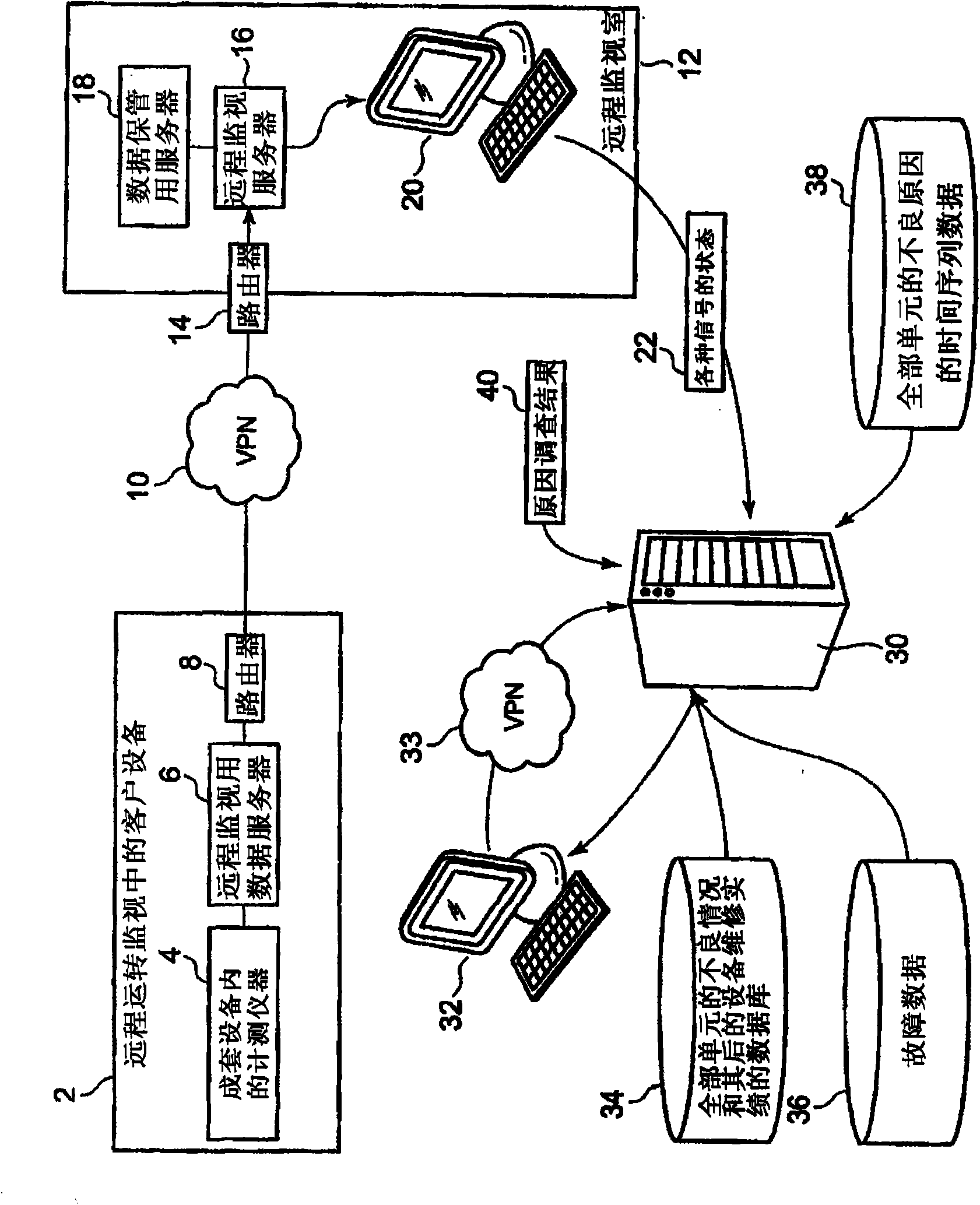

[0040] figure 1 It is a probabilistic configuration diagram of a remote management system for implementing the method for managing equipment failures of the present invention. In this embodiment, a method for managing a failure of equipment by using remote management is described as an example. Specifically, the maintenance experts of the equipment manufacturer monitor the operation status of the equipment constituting the complete equipment at a location far away from the above-mentioned complete equipment. ) to explain the management method of providing information.

[0041] as figure 1 The outline of the remote management system is that the operation data of the measuring instrument 4 in the plant is collected by using the data server for remote monitoring installed in the client equipment (hereinafter referred to as the plant) 2 in the remote operation monitoring, and the operation data is collected by the communication line. By transmitting the data to the remote monit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com