Motor control method, motor control device, fan device, compressor, and pump device

A control device and control method technology, applied in the direction of single motor speed/torque control, electronic commutator, etc., can solve problems such as speed instability, achieve the effects of improving efficiency, avoiding excessive shortening of intervals, and reducing detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

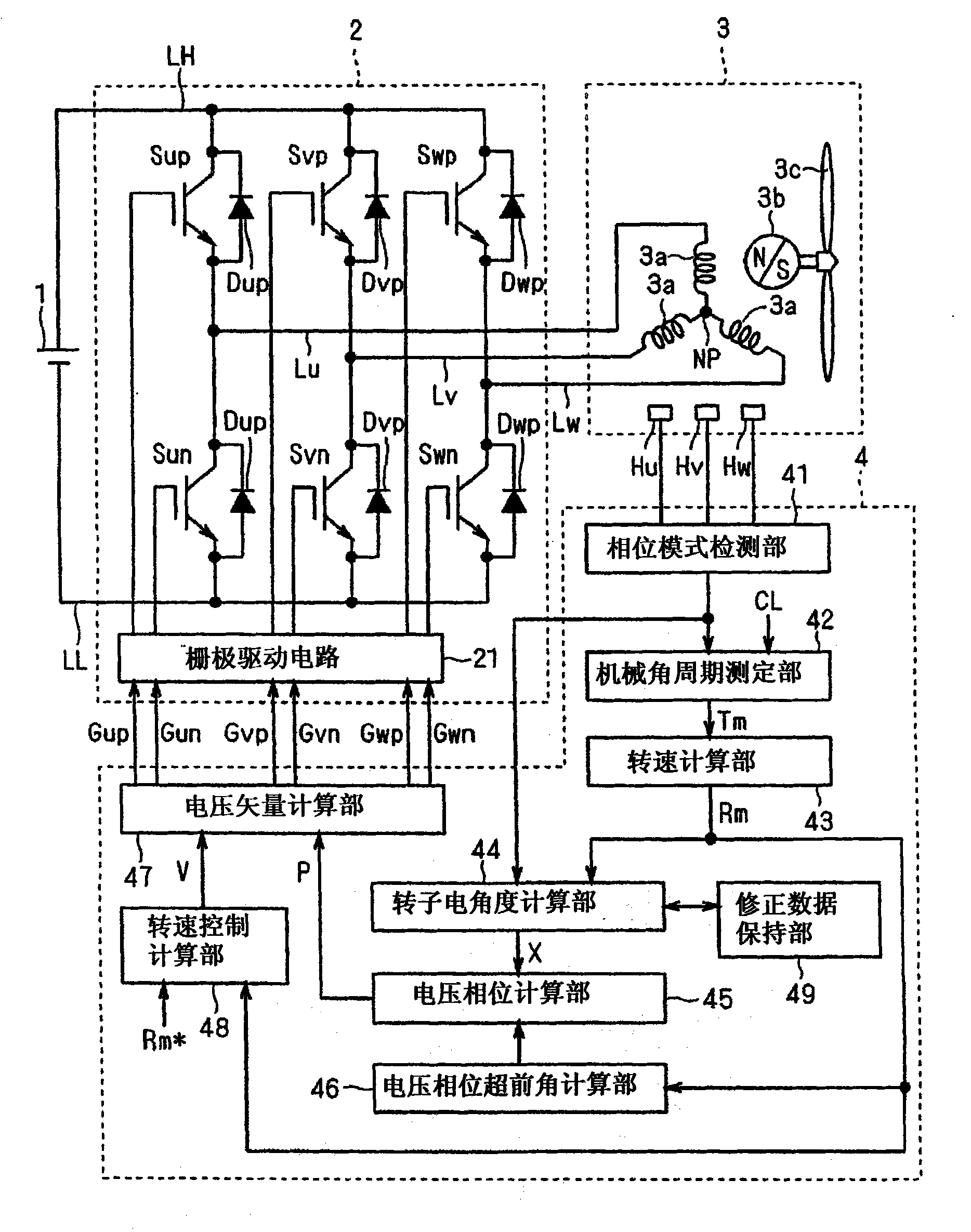

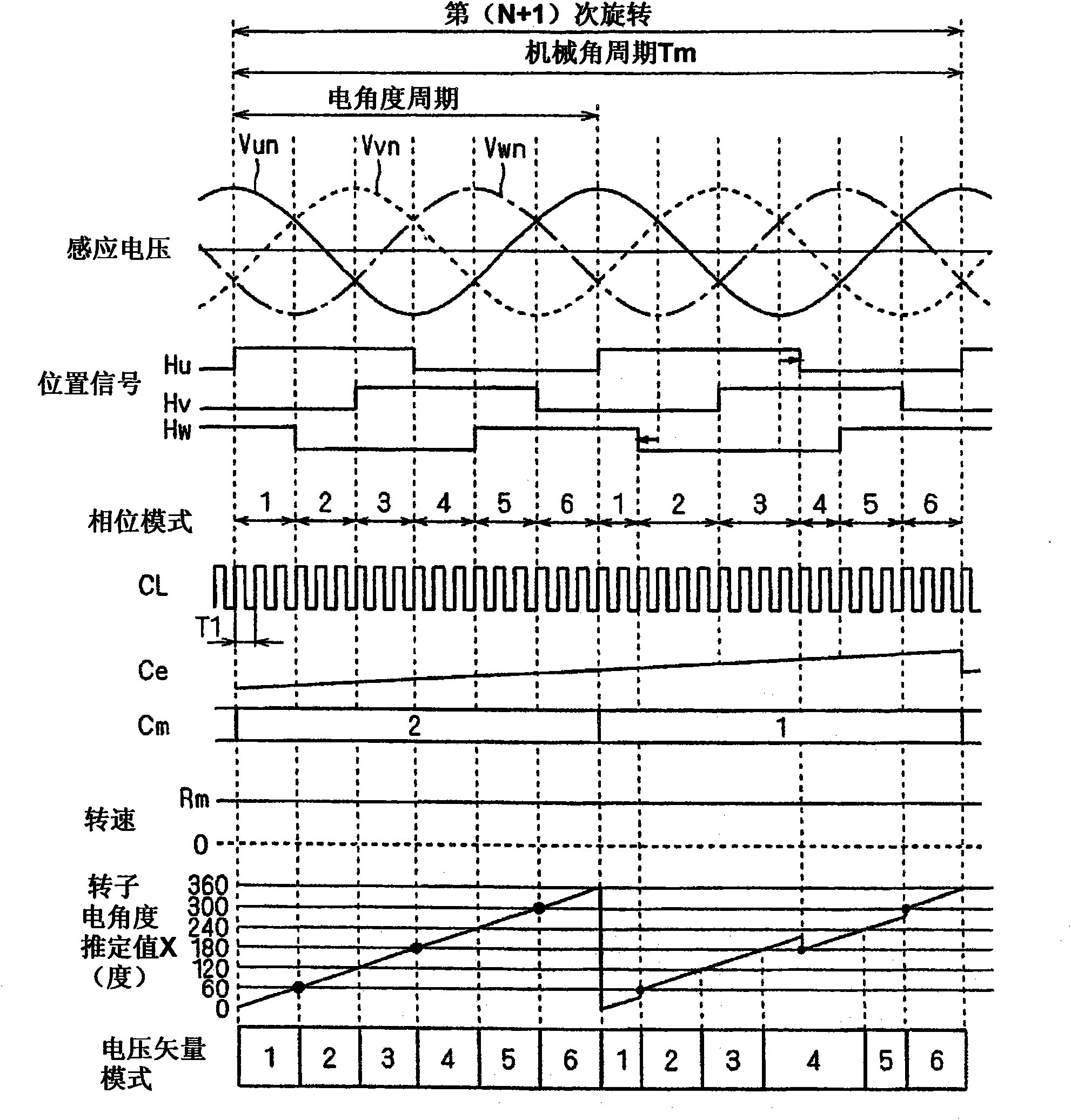

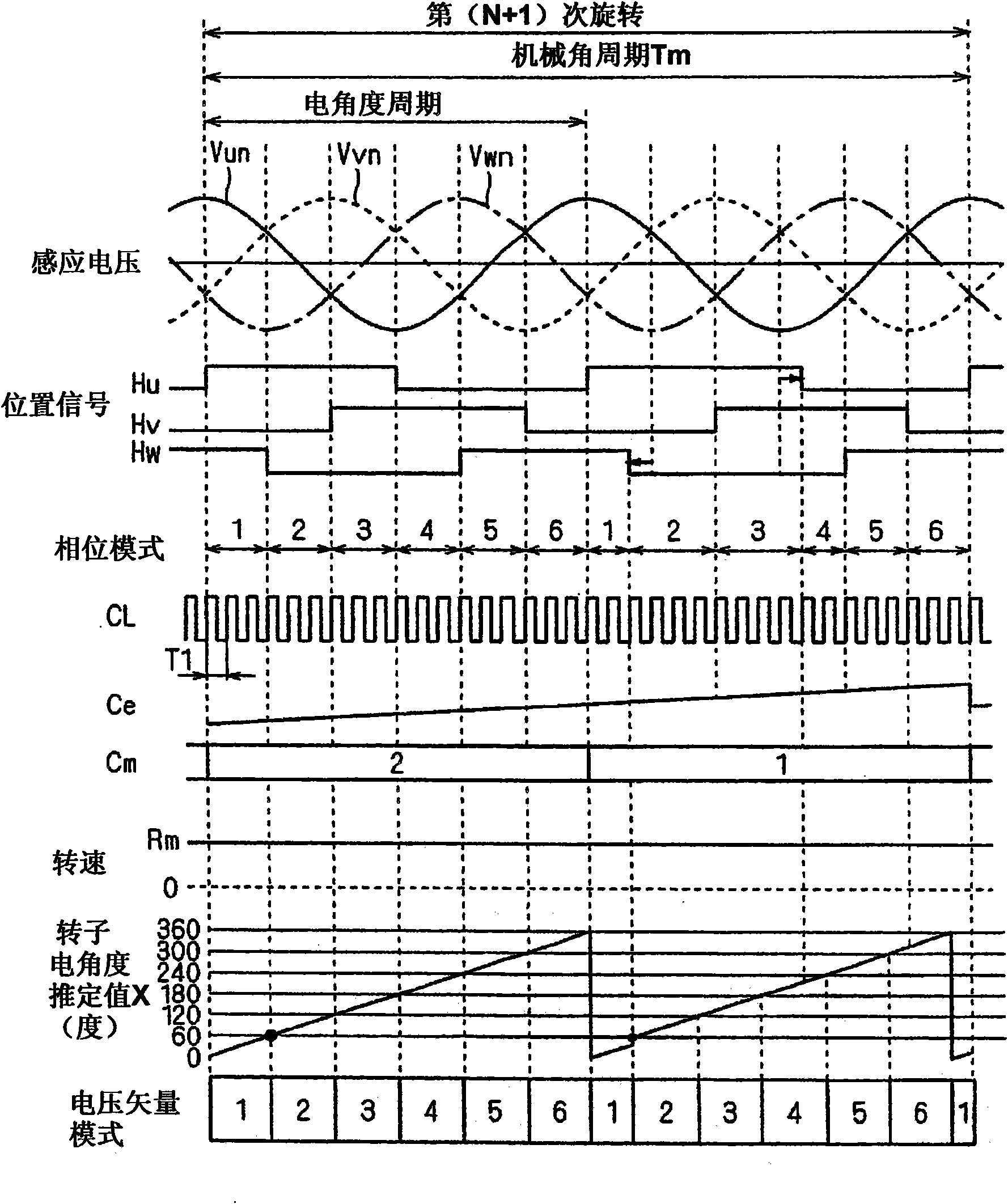

[0033] figure 1 An example of the conceptual configuration of the motor control device is shown. The motor control device includes a DC power supply 1 , an inverter 2 , a gate drive circuit (a grid drive circuit) 21 , a motor 3 , position detection sensors Hu, Hv, and Hw, and a control unit 4 . The control unit 4 includes: a phase pattern detection unit 41, a mechanical angle period measurement unit 42, a rotational speed calculation unit 43, a rotor electrical angle calculation unit 44, a voltage phase calculation unit 45, a voltage phase lead angle calculation unit 46, a voltage vector calculation unit 47, A rotational speed control calculation unit 48 and a correction data storage unit 49 .

[0034] The DC power supply 1 applies a DC voltage Vdc between the DC power supply lines LH, LL.

[0035] The inverter 2 includes an upper arm (high arm) side switching element Sxp (where x represents u, v, and w; hereinafter, the same applies), a lower arm (high arm) side switching e...

no. 2 Embodiment approach

[0102] In the first embodiment, a fan motor including a fan 3 c was exemplified as the motor 3 . In the second embodiment, another product incorporating the motor control device described in the first embodiment will be described. However, the motor does not include the fan 3c.

[0103] Figure 7 It is a figure which shows an example of the conceptual structure of a compressor. The compressor 50 includes a motor drive unit 10 , a compression mechanism 51 , a suction pipe 52 , a discharge pipe 53 , and a shaft 54 . The compressor 50 is mounted, for example, on an air conditioner.

[0104] The motor drive device 10 is the motor drive device described in the first embodiment (only the motor 3 has no fan).

[0105] The compression mechanism 51 is driven by the motor drive 10 via a shaft 54 . The compression mechanism 51 has a compression chamber 55 . The volume of the compression chamber 55 is reduced by the rotation of the motor 3 . The compression chamber 55 connects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com