Grating plate for sliding tongue plate of electromagnetic glove machine

A technology of glove machine and electromagnet, which is applied in textile and paper making, weft knitting, knitting and other directions, can solve the problems of fragile needle drum, limited number of needle drum horizontal grooves, time-consuming and labor-consuming, etc. Long-life, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

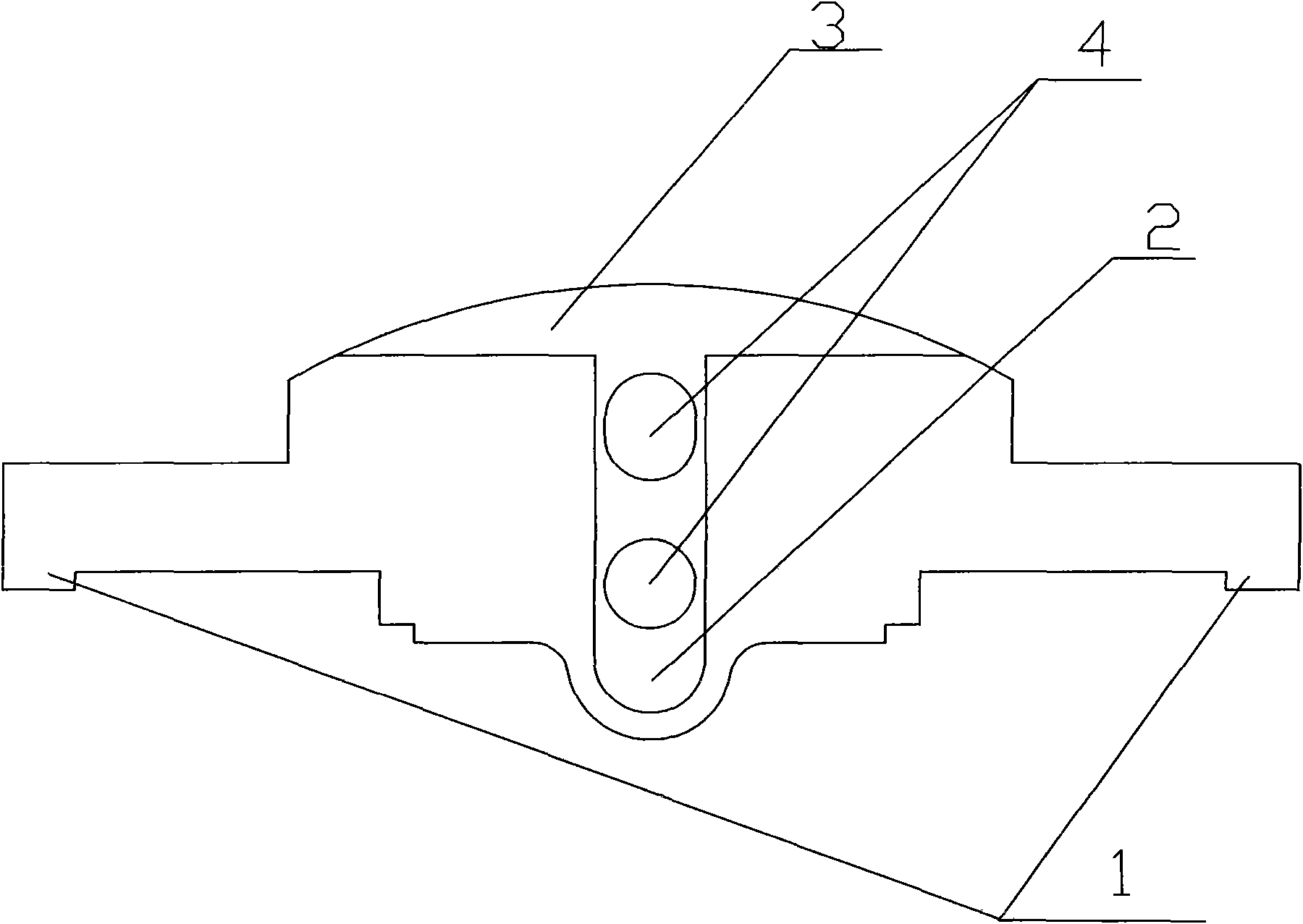

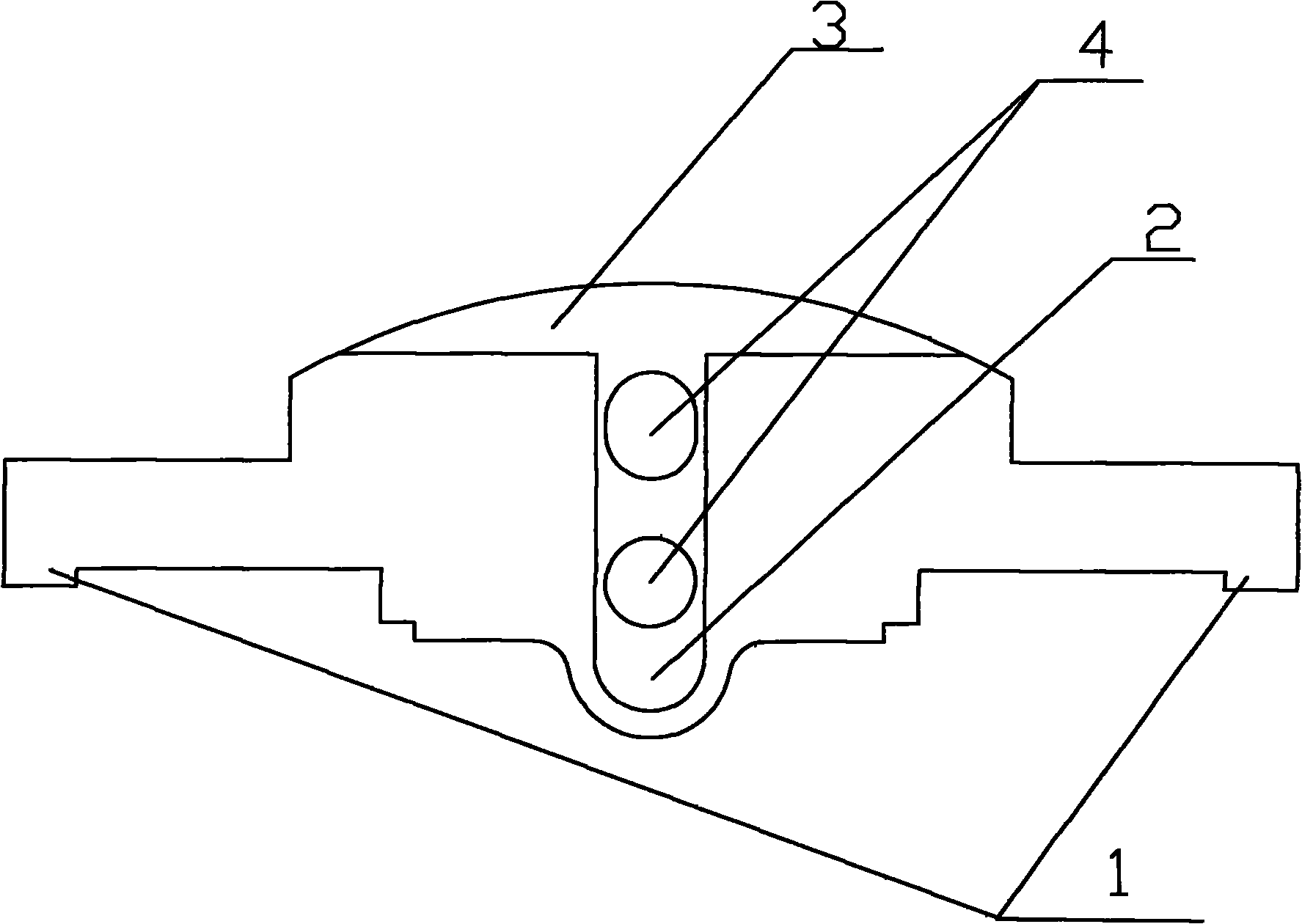

[0011] like figure 1 As shown, a grid used on the sliding tongue of the electromagnet glove machine has buckles 1 at both ends, and the buckles 1 are used to snap and install on the grid plate of the electromagnet glove machine; the longitudinal position of the middle of the grid is There is a chute 2, and the function of the chute 2 is just enough to place the sliding top block, which is used to jack up the swing rod; a movement groove 3 is arranged horizontally on the grid at the top of the chute 2, and the movement groove 3 is used for placing the bird pieces. ; There are two holes 4 on the chute 2 . The diameter of the hole 4 is 5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com