Restricted buckling restrained brace with parallel energy-dissipation mild steel plate and manufacturing method thereof

A technology of anti-buckling braces and manufacturing methods, which is applied in the direction of earthquake resistance and building components, etc., can solve problems such as buckling-resistant brace instability, easy buckling of connecting parts, and difficulty in establishing buckling-resistant brace design methods, so as to eliminate instability and avoid The effect of overall instability and avoiding premature yielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

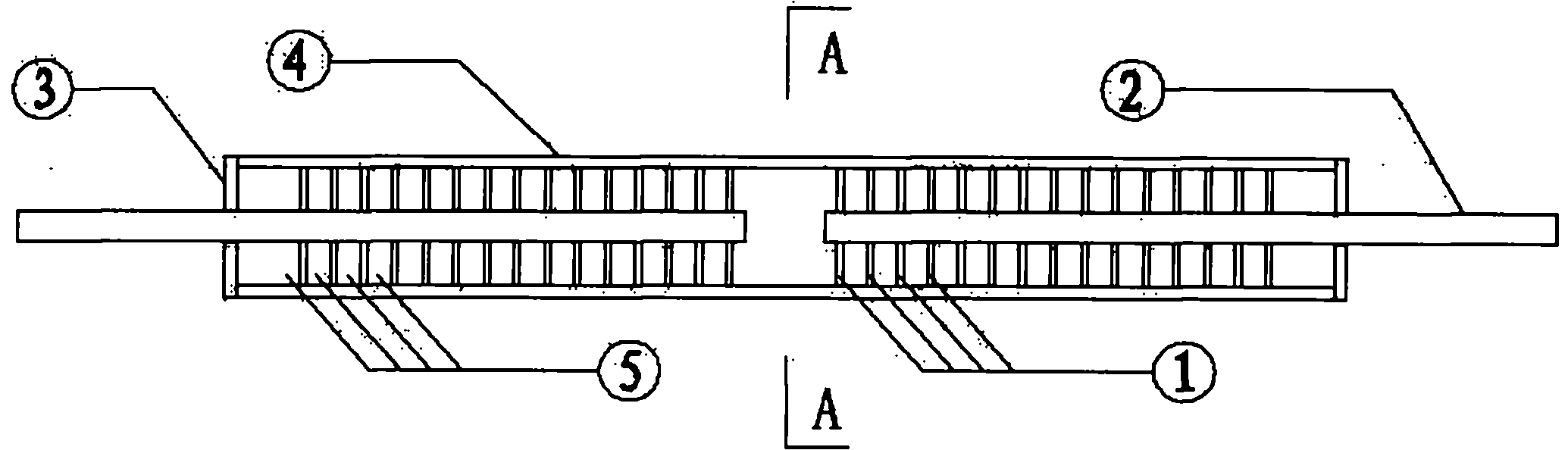

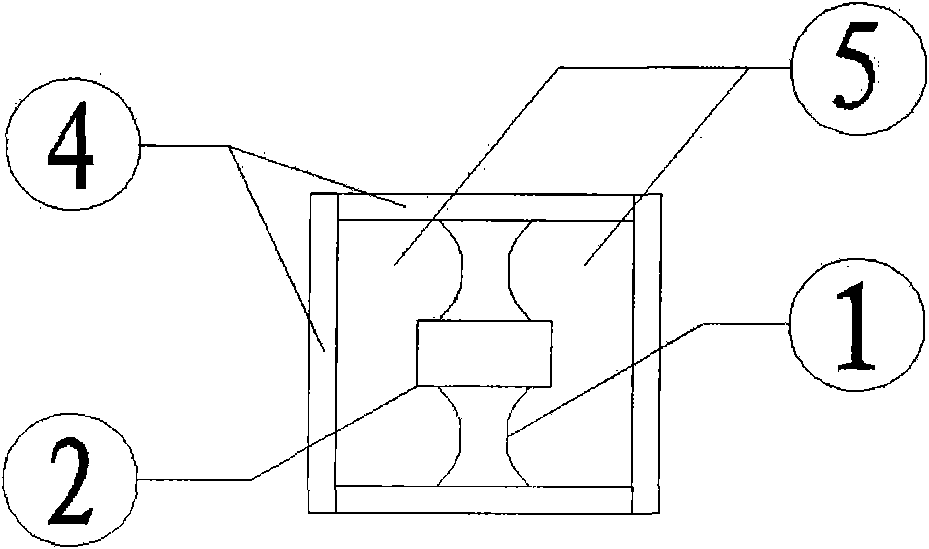

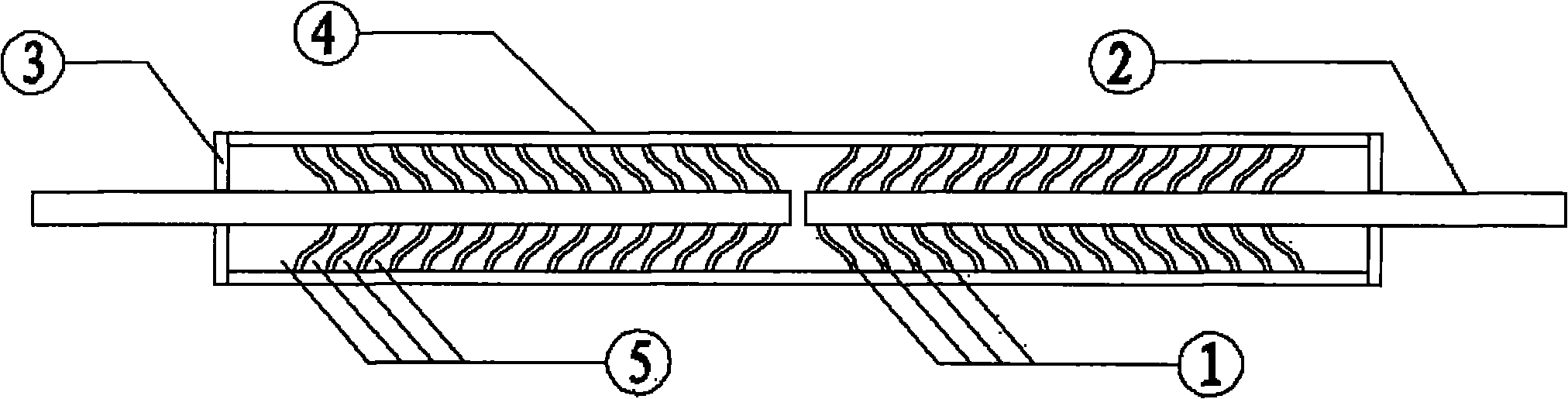

[0033] Both ends of the outer steel pipe are equipped with parallel energy-dissipating soft steel plate constrained buckling-resistant braces with inner steel plates, such as Figure 1 ~ Figure 4 . The parallel energy-dissipative mild steel plate constrained buckling-resistant brace of this embodiment includes an outer steel pipe, an inner steel plate 2 and a cluster of parallel energy-dissipative steel plates connecting these two parts. The outer steel pipe is welded by the outer steel pipe steel plate 4, and the outer Both ends of the steel pipe are provided with end steel plates 3 to seal the outer steel pipe. The inner steel plate 2 passes through the hole in the end steel plate 3 and is placed inside the outer steel pipe. Parallel energy-dissipating steel plates 1 arranged at equal intervals are vertically welded between them to form a cluster of parallel energy-dissipating steel plates. Foaming agent 5 is used to prevent moist air from contacting steel and welds. The p...

Embodiment 2

[0044] This example Figure 5 ~ Figure 7 , its structure and manufacturing method are basically the same as in Example 1, the only difference is that the inner steel plate 2 is one piece, and the inner steel plate 2 passes through the end steel plate 3 hole at one end of the outer steel pipe and is placed inside the steel pipe , the inner steel plate 2 keeps a certain distance from the end steel plate 3 at the other end of the outer steel pipe. That is, the internal steel plate 2 in this embodiment is only arranged at one end of the outer steel pipe, and the steel plate at the other end is closed and welded on it to the end connected with the structural member, thereby forming a parallel energy-dissipating mild steel plate-constrained anti-corrosion Buckling brace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com